Introduction to Conductive Threads

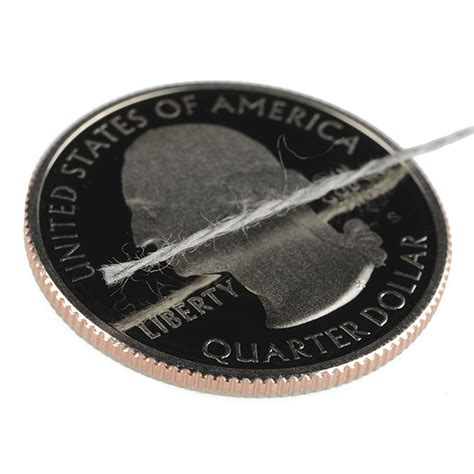

Conductive threads are revolutionizing the world of smart textiles by providing flexible and seamless electrical pathways that can be easily integrated into fabrics. These innovative threads, made from materials like silver, copper, or carbon, allow for the creation of wearable technology, interactive garments, and high-tech fabrics with unique functionalities.

In this comprehensive article, we will delve into the world of conductive threads, exploring their properties, applications, and the potential they hold for the future of smart textiles. We will also discuss the challenges and considerations associated with using conductive threads in various projects.

Properties of Conductive Threads

Conductivity and Resistance

One of the key properties of conductive threads is their ability to conduct electricity. The conductivity of a thread depends on the material it is made from and its cross-sectional area. Silver and copper threads generally have higher conductivity compared to carbon-based threads.

The resistance of a conductive thread is another important factor to consider. Resistance is the measure of a material’s opposition to the flow of electric current. The resistance of a thread depends on its length, cross-sectional area, and the inherent resistivity of the material. Longer threads and threads with smaller cross-sectional areas will have higher resistance.

Flexibility and Durability

Conductive threads are designed to be flexible, allowing them to be easily sewn, embroidered, or woven into fabrics without compromising their electrical properties. This flexibility is crucial for creating comfortable and wearable smart textiles that can conform to the body’s movements.

Durability is another essential property of conductive threads. They must be able to withstand repeated bending, stretching, and washing without losing their conductivity or breaking. High-quality conductive threads are often coated with protective layers to enhance their durability and resistance to wear and tear.

Applications of Conductive Threads

Wearable Electronics

Conductive threads have opened up a world of possibilities for wearable electronics. By integrating these threads into garments, designers and engineers can create smart clothing that can monitor vital signs, control devices, or provide interactive experiences.

Some examples of wearable electronics using conductive threads include:

- Fitness trackers embedded in athletic wear

- Touch-sensitive control panels on jacket sleeves

- LED displays on t-shirts

- Heated gloves and jackets for cold weather

Soft Sensors

Conductive threads can also be used to create soft sensors that can detect various stimuli, such as pressure, strain, or temperature. These sensors are highly flexible and can be seamlessly integrated into fabrics, making them ideal for a wide range of applications.

Examples of soft sensors using conductive threads include:

- Pressure-sensitive insoles for gait analysis

- Strain sensors for monitoring joint movements

- Temperature sensors for measuring body or environmental temperature

Smart Textiles for Healthcare

The healthcare industry is increasingly exploring the potential of smart textiles powered by conductive threads. These innovative fabrics can be used for remote patient monitoring, rehabilitation, and assistive technologies.

Some examples of smart textiles for healthcare include:

- ECG monitoring garments for continuous heart rate tracking

- Compression stockings with integrated pressure sensors for managing lymphedema

- Smart bandages that can detect wound healing progress

Interactive Art and Fashion

Conductive threads have also found their way into the world of art and fashion, enabling designers to create interactive and expressive garments and installations. By combining conductive threads with sensors, actuators, and microcontrollers, artists and fashion designers can push the boundaries of creativity and user engagement.

Examples of interactive art and fashion using conductive threads include:

- Dresses that change color based on the wearer’s movements

- Interactive tapestries that respond to touch or proximity

- Light-up costumes for performers and dancers

Challenges and Considerations

Washing and Maintenance

One of the challenges associated with using conductive threads in smart textiles is washing and maintenance. Exposure to water, detergents, and mechanical stress during washing can potentially damage the conductive threads or affect their electrical properties.

To address this challenge, researchers and manufacturers are developing washable conductive threads and protective coatings that can withstand multiple wash cycles. It is also essential to follow proper care instructions and consider the placement of electronic components to minimize damage during washing.

Electrical Insulation

When working with conductive threads, electrical insulation is a crucial consideration. Unintended contact between conductive threads can lead to short circuits, which can damage electronic components or cause malfunctions.

To prevent short circuits, conductive threads can be insulated using materials like silicone, polyurethane, or enamel. Insulation also helps to protect the threads from abrasion and environmental factors that can degrade their performance over time.

Connectivity and Power Supply

Integrating conductive threads into smart textiles often requires connecting them to electronic components, such as sensors, actuators, or microcontrollers. Ensuring reliable and stable connections between the threads and these components is essential for the proper functioning of the system.

Various methods can be used to establish connections, including soldering, crimping, or using conductive adhesives. It is important to choose the appropriate method based on the project requirements and the compatibility of the materials involved.

Powering smart textiles is another consideration. Depending on the application, smart textiles may require a power source, such as a battery or energy harvesting system. The power supply should be carefully selected to ensure sufficient capacity, safety, and compatibility with the conductive threads and electronic components.

Table: Comparison of Common Conductive Thread Materials

| Material | Conductivity | Durability | Flexibility | Cost |

|---|---|---|---|---|

| Silver | High | High | High | High |

| Copper | High | Medium | Medium | Medium |

| Stainless Steel | Medium | High | Low | Low |

| Carbon | Low | Medium | High | Low |

Frequently Asked Questions (FAQ)

1. What is the difference between conductive threads and regular threads?

Conductive threads are specially designed threads that can conduct electricity, while regular threads are not conductive. Conductive threads are made from materials like silver, copper, or carbon, which allow them to carry electrical current, enabling the creation of electrical pathways in fabrics.

2. Can conductive threads be sewn using a regular sewing machine?

Yes, conductive threads can be sewn using a regular sewing machine. However, it is essential to use a needle suitable for the thread material and adjust the tension settings accordingly. It is also recommended to use a dedicated bobbin and spool for conductive threads to avoid contamination with regular threads.

3. How do I choose the right conductive thread for my project?

Choosing the right conductive thread depends on several factors, including the desired conductivity, flexibility, durability, and cost. Consider the specific requirements of your project, such as the level of electrical resistance needed, the amount of strain the thread will be subjected to, and the overall budget. Refer to the comparison table in this article for a general overview of common conductive thread materials and their properties.

4. Can conductive threads be used for outdoor applications?

Conductive threads can be used for outdoor applications, but it is essential to consider the environmental factors that may affect their performance and durability. Exposure to moisture, UV radiation, and extreme temperatures can degrade the conductive properties of the threads over time. To ensure the longevity of outdoor projects, choose conductive threads with appropriate protective coatings and follow proper encapsulation techniques to shield the threads from the elements.

5. Are there any safety concerns when working with conductive threads?

When working with conductive threads, it is crucial to take necessary safety precautions to avoid electrical hazards. Always ensure proper insulation of the conductive threads to prevent short circuits and unintended electrical contact. Be cautious when connecting conductive threads to power sources and electronic components, and follow the manufacturer’s guidelines for handling and usage. If you are unsure about the safety aspects of your project, consult with an experienced electrical engineer or refer to relevant safety standards and guidelines.

Conclusion

Conductive threads have emerged as a game-changer in the field of smart textiles, enabling the creation of flexible, wearable, and interactive electronic systems. With their unique properties and diverse applications, conductive threads are transforming the way we interact with clothing and fabrics.

From wearable electronics and soft sensors to healthcare monitoring and interactive art installations, the possibilities offered by conductive threads are vast and exciting. As research and development in this field continue to advance, we can expect to see even more innovative and revolutionary applications of conductive threads in the future.

However, working with conductive threads also presents certain challenges and considerations, such as washing and maintenance, electrical insulation, and connectivity. By understanding these challenges and adopting appropriate strategies, designers, engineers, and makers can successfully harness the potential of conductive threads in their projects.

As the world of smart textiles continues to evolve, conductive threads will undoubtedly play a pivotal role in shaping the future of wearable technology and interactive fabrics. Embracing the opportunities offered by conductive threads will lead to the development of more seamless, functional, and expressive smart textile solutions that blend technology with the comfort and aesthetics of traditional fabrics.

Leave a Reply