Introduction to Circuit Board Headers

Circuit board headers are essential components in electronic systems, providing a reliable and efficient way to establish electrical connections between printed circuit boards (PCBs) and other devices or modules. These single-block connectors come in various shapes, sizes, and pin configurations to accommodate different design requirements. In this comprehensive article, we will explore the world of circuit board headers, their types, applications, and key considerations when selecting and using them in electronic projects.

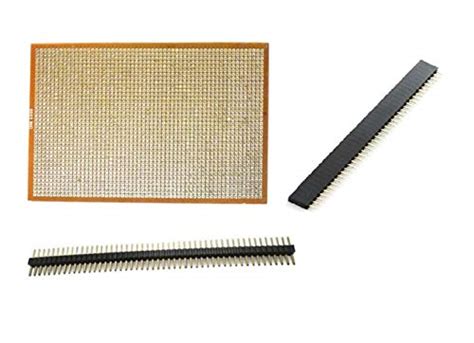

What are Circuit Board Headers?

Circuit board headers, also known as pin headers or header connectors, are single-block electrical connectors that consist of a row or matrix of male pins arranged in a specific pattern. These pins are typically made of gold-plated or tin-plated metal and are designed to be soldered onto a PCB. The header provides a connection point for mating with a corresponding female connector, such as a socket or a cable assembly.

Types of Circuit Board Headers

There are several types of circuit board headers available, each with its own characteristics and applications. Let’s explore some of the most common types:

1. Single Row Headers

Single row headers are the most basic type of circuit board headers. They consist of a single row of male pins, typically spaced at a pitch of 2.54mm (0.1 inches). Single row headers are commonly used for low-density connections, such as power supply, control signals, or low-speed data transmission.

2. Dual Row Headers

Dual row headers feature two parallel rows of male pins, allowing for a higher density of connections compared to single row headers. The pins are usually arranged in a staggered or in-line configuration, with a pitch of 2.54mm (0.1 inches) between rows. Dual row headers are widely used for applications that require more pins, such as microcontroller programming, data bus connections, or interfacing with displays and sensors.

3. Shrouded Headers

Shrouded headers, also known as box headers, are similar to single or dual row headers but feature a plastic shroud or housing that surrounds the pins. The shroud provides mechanical protection, prevents accidental contact with the pins, and helps guide the mating connector for proper alignment. Shrouded headers are commonly used in applications where increased reliability and protection are required, such as in automotive or industrial environments.

4. Surface Mount Headers

Surface mount headers are designed for surface mount technology (SMT) assembly processes. Instead of through-hole pins, surface mount headers have flat or gull-wing leads that are soldered directly onto the surface of the PCB. Surface mount headers offer several advantages, including reduced board space, improved mechanical stability, and compatibility with automated assembly processes.

Applications of Circuit Board Headers

Circuit board headers find applications in a wide range of electronic systems and devices. Some common applications include:

- Microcontroller and single-board computer interfacing

- Expansion boards and shields for development platforms like Arduino and Raspberry Pi

- Connecting displays, sensors, and actuators to PCBs

- Establishing power and ground connections

- Interfacing with communication modules (e.g., Wi-Fi, Bluetooth, GPS)

- Connecting multiple PCBs or modules in a stacked configuration

- Providing test points or programming interfaces for debugging and firmware updates

Selecting the Right Circuit Board Header

When choosing a circuit board header for your project, several factors should be considered to ensure optimal performance and reliability:

1. Pin Count and Pitch

Determine the number of pins required for your application and select a header with the appropriate pin count. Consider the available PCB space and the pitch of the pins (distance between adjacent pins) to ensure compatibility with your design.

2. Current Rating and Voltage Rating

Evaluate the current and voltage requirements of your application and choose a header with suitable ratings. Make sure the header can handle the maximum expected current and voltage levels without exceeding its specifications.

3. Plating Material

Circuit board headers are available with different plating materials, such as gold or tin. Gold-plated headers offer superior corrosion resistance and improved electrical conductivity, making them suitable for high-reliability applications. Tin-plated headers are more cost-effective and provide good solderability.

4. Mechanical Considerations

Consider the mechanical aspects of your design, such as the mating connector type, board-to-board spacing, and any physical constraints. Ensure that the selected header is compatible with the mating connector and provides secure and reliable connections.

5. Environmental Factors

Take into account the environmental conditions in which your electronic system will operate. If the device will be exposed to harsh environments, such as extreme temperatures, humidity, or vibrations, choose a header with appropriate ratings and protection features.

Best Practices for Using Circuit Board Headers

To ensure optimal performance and reliability when using circuit board headers, follow these best practices:

- Properly design the PCB layout, considering the header’s footprint, pin spacing, and any required clearances.

- Use appropriate soldering techniques, such as reflow soldering for surface mount headers or wave soldering for through-hole headers, to achieve reliable solder joints.

- Apply proper mating force when connecting the header to its corresponding connector to prevent damage to the pins or the PCB.

- Consider using strain relief mechanisms, such as cable ties or connector housings, to reduce mechanical stress on the header and the PCB.

- Follow the manufacturer’s recommendations for handling, storage, and assembly to maintain the integrity of the headers.

Frequently Asked Questions (FAQ)

1. What is the difference between a single row and a dual row header?

A single row header consists of a single row of male pins, while a dual row header features two parallel rows of pins. Dual row headers provide a higher density of connections compared to single row headers, allowing for more pins in a given PCB space.

2. Can I use a surface mount header in a through-hole PCB design?

While it is possible to use a surface mount header in a through-hole PCB design, it is not recommended. Surface mount headers are designed for surface mount assembly processes and may not provide the same mechanical stability or reliability when used with through-hole mounting. It is best to use headers specifically designed for through-hole mounting in such cases.

3. What is the purpose of a shrouded header?

A shrouded header, also known as a box header, features a plastic shroud or housing that surrounds the pins. The shroud provides mechanical protection, prevents accidental contact with the pins, and helps guide the mating connector for proper alignment. Shrouded headers are commonly used in applications where increased reliability and protection are required.

4. How do I determine the current rating of a circuit board header?

The current rating of a circuit board header depends on various factors, such as the pin size, plating material, and ambient temperature. Refer to the manufacturer’s datasheet or specifications to determine the maximum current rating for the specific header you are using. It is important to ensure that the header’s current rating is sufficient for your application’s requirements.

5. Can I mix and match headers from different manufacturers?

While it is possible to mix and match headers from different manufacturers, it is generally recommended to use headers from the same manufacturer to ensure compatibility and reliability. Different manufacturers may have slight variations in pin dimensions, tolerances, or materials, which could lead to issues with mating connectors or long-term reliability. If mixing and matching is necessary, thoroughly test the compatibility and performance of the headers before finalizing your design.

| Header Type | Pin Count | Pitch | Applications |

|---|---|---|---|

| Single Row | 2-40 | 2.54mm | Power supply, control signals, low-speed data |

| Dual Row | 4-80 | 2.54mm | Microcontrollers, data buses, displays, sensors |

| Shrouded | 2-40 | 2.54mm | Automotive, industrial, high-reliability |

| Surface Mount | 2-80 | Various | Space-constrained designs, automated assembly |

Conclusion

Circuit board headers are vital components in electronic systems, providing reliable and efficient electrical connections between PCBs and other devices. Understanding the different types of headers, their applications, and key selection criteria is essential for designing robust and reliable electronic projects. By following best practices and considering factors such as pin count, current rating, plating material, and mechanical requirements, you can ensure optimal performance and longevity of your circuit board header connections.

As technology advances and electronic systems become more complex, the role of circuit board headers continues to evolve. Manufacturers are developing new header designs and materials to meet the demands of emerging applications, such as high-speed data transmission, miniaturization, and harsh environment operation. By staying informed about the latest advancements in circuit board header technology, electronic designers and engineers can create innovative and reliable solutions for a wide range of industries and applications.

Leave a Reply