Finding high-quality, yet affordable flexible printed circuit boards (flex PCBs) can be a challenge. Flex PCBs enable creative and compact product designs by allowing circuitry to bend and flex. However, the manufacturing process requires special materials and techniques, which can drive up costs. With some savvy sourcing strategies, you can find flex PCBs that meet your budget without sacrificing on quality.

What Are Flex PCBs and Why Are They More Expensive?

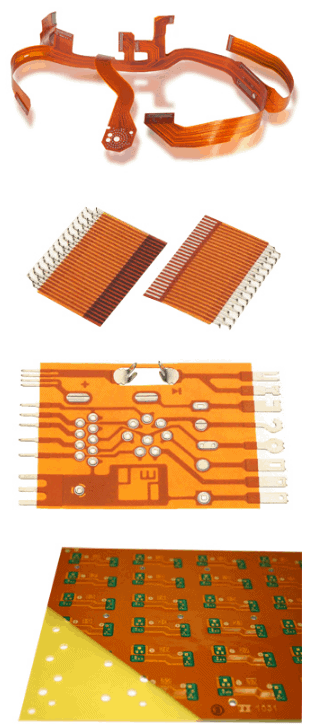

A flex PCB uses a flexible base material, usually a polyimide film, with conductive traces etched or printed on top. Here are some key properties and manufacturing requirements that make flex PCBs more costly than their rigid counterparts:

- Flexible base material – The flexible substrate materials are more expensive than the rigid FR-4 used in most PCBs. Polyimide films like Kapton are most commonly used.

- More complex processing – Flex PCB fabrication requires additional steps like laser direct imaging (LDI) and specialized etching processes. Handling thinner and flexible materials also requires more careful processing.

- Lower economies of scale – As flex PCB production volumes are lower than rigid PCBs, there are fewer economies of scale to help drive down costs.

- Testing challenges – It’s harder to test flex PCBs as the boards can’t be probed using pins. Testing needs to accommodate flexibility.

- Specialized design – Designing flex PCBs requires expertise to account for flexure, thermal expansion, and impedance control.

Tips for Sourcing Budget-Friendly Flex PCBs

While flex PCB costs are inherently higher, here are some tips for keeping costs down while still getting quality boards:

Choose an Experienced Flex PCB Manufacturer

Go with an established manufacturer that specializes in flex PCBs. They have the expertise to fabricate complex flexible boards cost-effectively. Avoid vendors that focus on rigid PCBs and only offer flex PCBs as an ancillary service.

Evaluate Location and Shipping

Pick a manufacturer with a location that offers affordable shipping to your location. For example, a China-based provider may offer low manufacturing costs, but shipping and customs can erase those savings. A vendor in your region may be pricier on manufacturing but have lower logistics costs.

Optimize Designs

Work closely with your vendor to optimize flex PCB designs. Simpler layouts and fewer layers will be cheaper. Also, minimize complex bends and thickness variations.

Order Larger Volumes

The more flex PCBs you order, the lower the cost per unit will be. Bulk ordering gives you better economies of scale. Though, make sure to balance lower costs with the risk of ordering too much inventory.

Consider Panelizing

Panelizing involves grouping multiple smaller PCBs together on a large panel that is manufactured, then separated. This allows more efficient processing of small flex PCBs, cutting costs.

Use Standard Materials and Thicknesses

Sticking to common materials like Polyimide and standard thicknesses will keep costs lower. Custom materials and thicknesses often have higher minimum order requirements too.

Allow Sufficient Lead Times

Rushing production with extremely short lead times will increase costs. Build in adequate lead time buffers to avoid expediting fees.

Leverage Purchasing Agreements

Larger buyers can negotiate purchasing agreements with defined pricing and terms upfront. This is a good way to lock in lower costs for scheduled procurements.

Avoid Unneeded High-End Features

Only pay for flex PCB features you actually require. Avoid specifications like extra dense interconnect (EDI) or lamination if not needed.

Where to Find Budget Flex PCB Manufacturing Services

Here are some recommendations on where to source lower cost, but quality flex PCBs:

- Local manufacturers – Look for providers in your area to save on shipping. They may offer competitive pricing.

- China manufacturers – Many China-based companies offer budget pricing for flex PCBs, though account for added shipping/duties.

- Online manufacturing marketplaces – Sites like PCBWay and PCBCart allow you to compare quotes from multiple providers.

- EDA vendor referrals – Consulting the flex PCB design software vendors you use for manufacturer recommendations can be helpful.

When reaching out to potential vendors, be sure to provide all the details on your flex PCB requirements, including:

- Layer count

- Board dimensions

- Bend radii

- Material type

- Thickness

- Quantity Needed

- Any other special requirements

This allows the manufacturer to accurately quote pricing based on your project’s complexity.

Key Flex PCB Specifications to Get Right

While seeking budget pricing, don’t sacrifice on quality by overlooking key specifications:

Number of Layers

The number of conductive copper layers in the flex PCB stackup impacts flexibility, thickness, and cost. Limit layers where possible.

Minimum Bend Radius

Specify how tight of a bend the PCB must withstand. Tighter bends limit material and thickness choices.

Board Thickness

Thicker boards are generally more expensive but offer better data performance. Find the right balance for your design.

Copper Weight

Heavier copper means thicker copper traces and has higher material costs. Only specify thicker copper (2 oz+) where needed.

Dielectric Material

Make sure the base polyimide film meets your flexibility and temperature requirements.

Board Dimensional Tolerances

Tighter tolerances on board dimensions and features will increase cost. Allow looser tolerances where possible.

Testing

Determine what testing needs to be performed, like netlist testing or AOI. This impacts cost.

Certifications

Any special certifications like UL recognition will increase cost. Only require necessary certs.

Carefully defining these parameters will help you get an accurate assessment of the manufacturing costs for your particular flex PCB design.

Evaluating Flex PCB Quality

When you receive flex PCB samples and production boards, here are some key aspects to inspect to ensure quality:

- Visually inspect boards for any damage, nicks, scuffs, or debris.

- Use a microscope to check trace definition, spacing, and etching.

- Verify board dimensional accuracy, including thickness.

- Confirm plating quality on vias and through-holes.

- Review lamination for any delamination or adhesive leakage.

- Functionally test boards with simple connectivity or continuity checks.

- Assess flexibility by bending boards to match intended radii.

- If possible, perform automated optical inspection (AOI).

Catching any quality issues early allows you to address them with your supplier promptly.

FQA about Cheap Flex PCBs

Here are answers to some frequently asked questions about sourcing budget flex PCBs:

Q: How cheap can I realistically get flex PCBs?

There is no one cheapest price as it depends on your particular design’s complexity. As a rough estimate, basic 2-4 layer flex boards in small volumes can range from $100 – $500 for ~10 boards. The key is finding the optimal balance of design, materials, volume, and manufacturer to minimize costs.

Q: Should I be wary of extremely cheap flex PCB pricing?

Very cheap flex PCBs may seem appealing but could signal quality problems down the road. Incredibly low pricing likely means cut corners in materials, testing, or processes. Prioritize quality vendors known for making reliable, functional boards in your budget range.

Q: Are there any hidden gotchas with lower-cost flex PCB suppliers?

Watch out for vendors that seem to have very attractive pricing but then charge exorbitant shipping fees or other hidden costs. Also beware of vendors advertising unusually fast lead times – this can mean they pre-build boards before receiving your order, creating risk of errors.

Q: Can I design a flex PCB myself to save costs?

While DIY designs may seem cheaper, they require extensive expertise to get right. Design flaws that require multiple manufacturing iterations to fix can become quite costly. Leveraging an experienced design firm for your flex PCB layout is recommended, despite the higher upfront cost.

Q: Should I avoid budget flex PCB manufacturers in China?

Not necessarily. Many reputable Chinese companies offer quality flex PCB production at competitive prices. Just do your homework to vet the supplier based on experience, certifications, customer reviews, communication practices, etc. Some indicate lower quality but there are plenty of “diamond in the rough” vendors to find.

Conclusion

Finding flexible PCB solutions to fit small budgets is achievable with careful sourcing techniques. Focus first on optimizing your design, then look for experienced manufacturers that can fabricate your boards reliably and cost-effectively. With a strategic approach, you can acquire high-quality flex PCBs to enable your product’s unique form and function without breaking the bank.

Leave a Reply