ALL ABOUT FLEX PCB

-

The Strength and Flexibility of Polyimide Films

Posted by

–

Read more: The Strength and Flexibility of Polyimide Films

Read more: The Strength and Flexibility of Polyimide FilmsPolyimide film, often referred to by the DuPont tradename Kapton, is an incredibly versatile material known for its outstanding thermal, mechanical, and chemical properties. Polyimide films are used in a wide variety of industries and applications including flexible printed circuits (flex PCBs), wire and cable insulation, automotive engine components, aerospace […]

-

Dual Layer PCBs: A Complete Guide

Posted by

–

Read more: Dual Layer PCBs: A Complete Guide

Read more: Dual Layer PCBs: A Complete GuideIntroduction Printed circuit boards (PCBs) form the backbone of most modern electronic devices. From smartphones to TVs to computers, PCBs provide the platform to mount and connect electronic components using conductive copper traces. As electronic devices become more complex and packed with features, PCBs too have evolved to accommodate more […]

-

Factors That Determine Flex PCB Cost

Posted by

–

Read more: Factors That Determine Flex PCB Cost

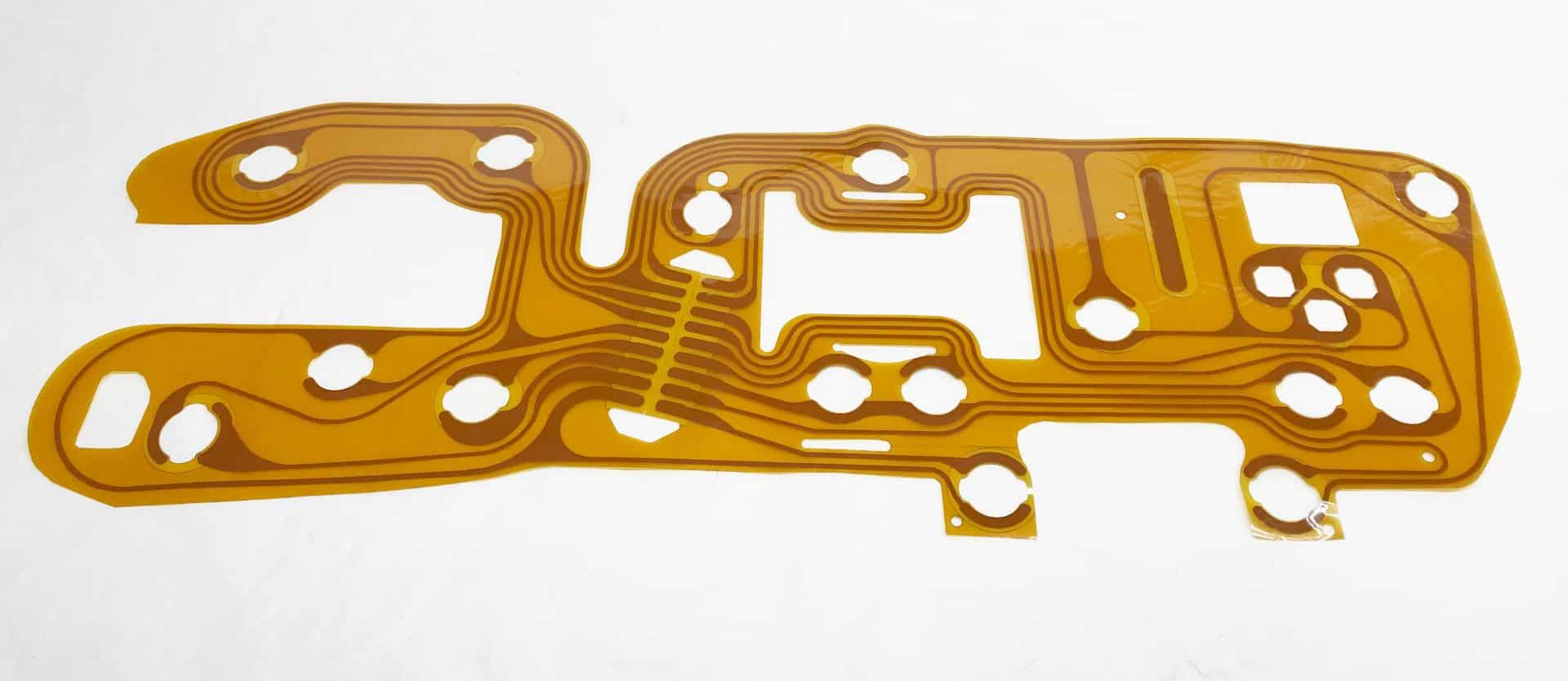

Read more: Factors That Determine Flex PCB CostIntroduction Printed circuit boards (PCBs) are essential components in nearly all modern electronic devices. Flexible PCBs, also known as flex PCBs, offer advantages over rigid PCBs in applications where flexibility is required. As flex PCBs become more widely used, understanding the factors that determine their cost is important for designers […]

-

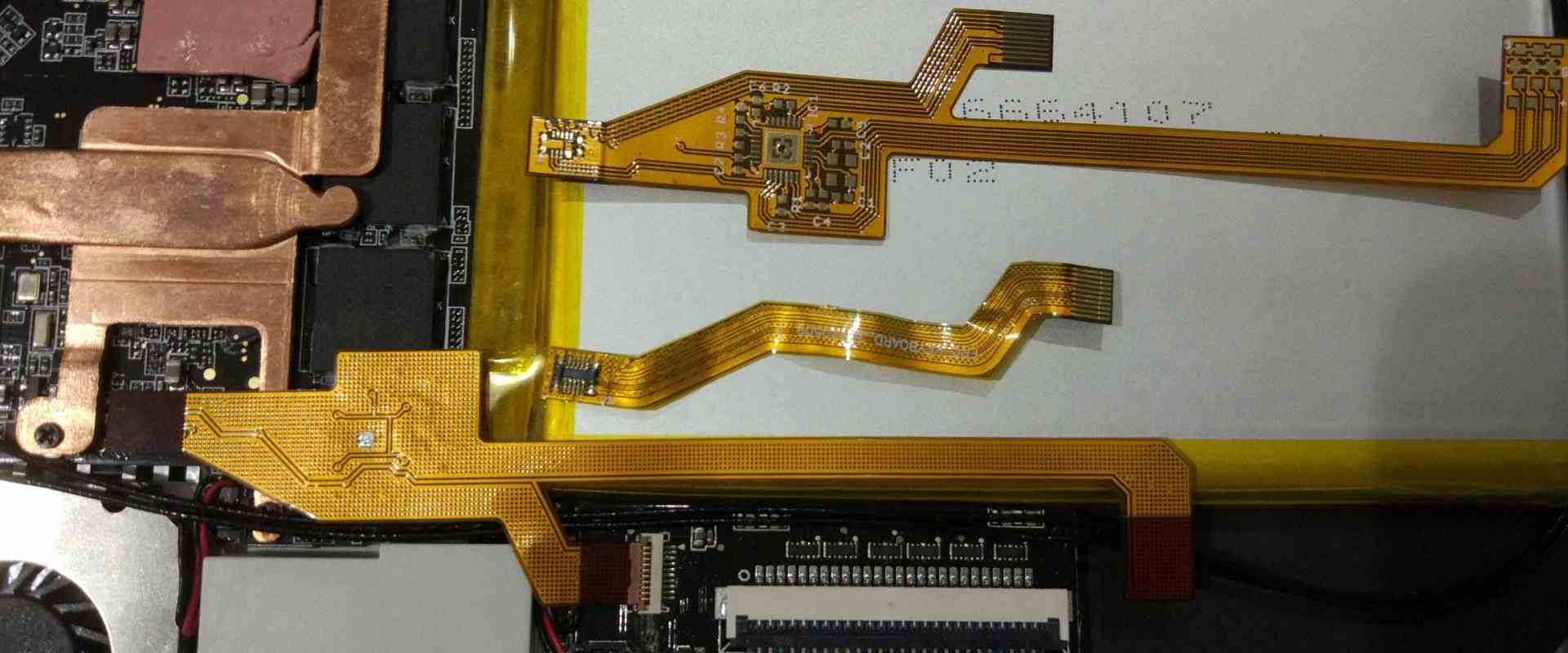

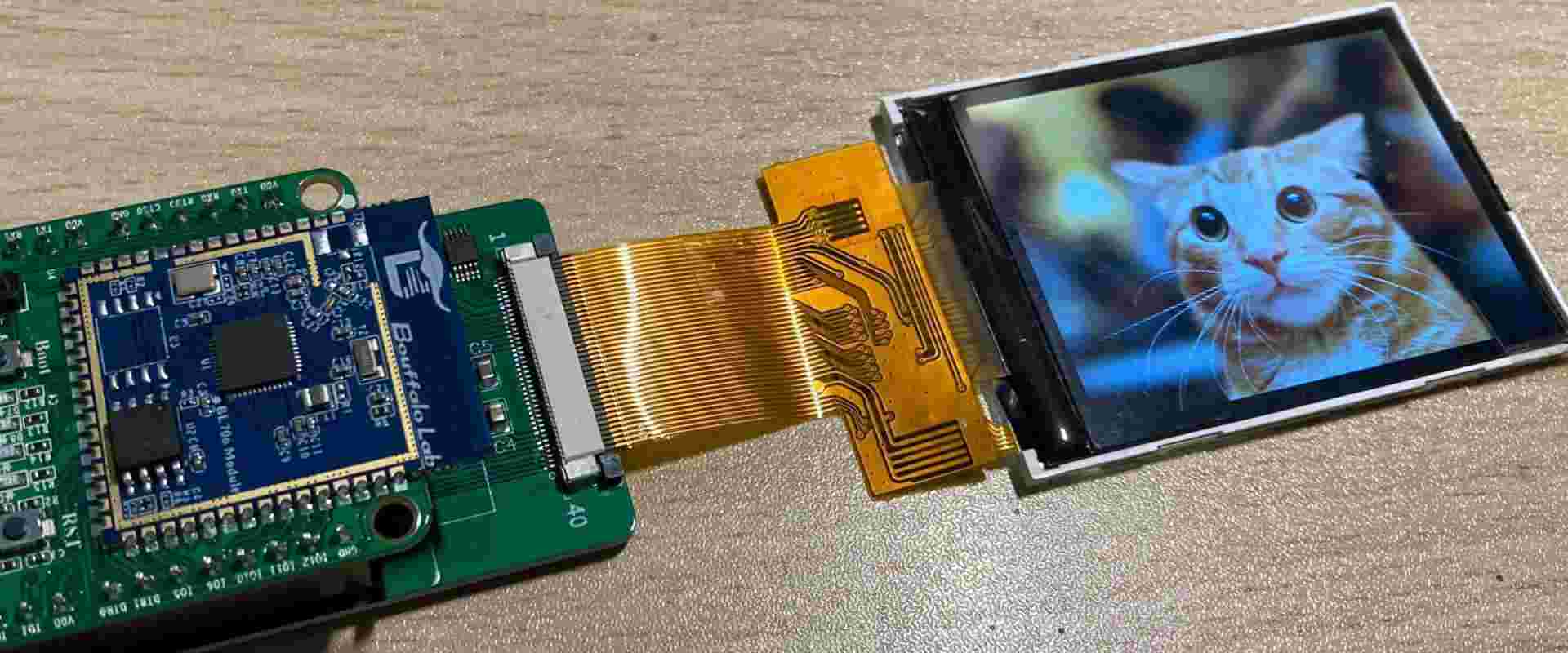

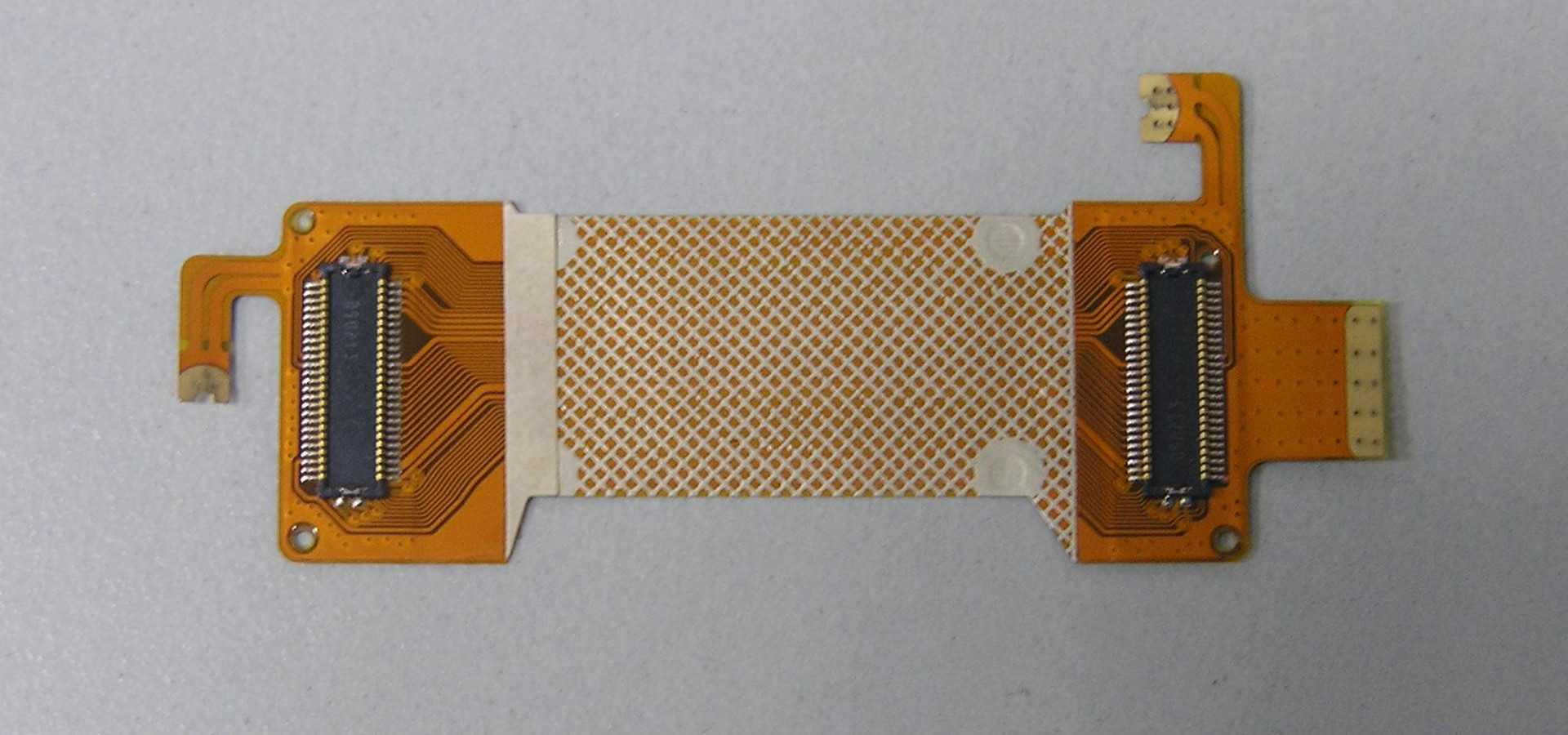

Read more: Flexible Printed Circuit Board (Flex PCB) Manufacturing

Read more: Flexible Printed Circuit Board (Flex PCB) ManufacturingFlexible printed circuit boards (flex PCBs) are a type of printed circuit board made with flexible substrate materials such as polyimide and polyester. Flex PCBs can be bent, folded, and twisted to fit into tight spaces and movable configurations. They are commonly used in consumer electronics, medical devices, automotive electronics, […]

-

The Role of FR4 Stiffeners in PCB Design

Posted by

–

Read more: The Role of FR4 Stiffeners in PCB Design

Read more: The Role of FR4 Stiffeners in PCB DesignWhat is FR4? FR4 is a grade designation assigned to glass-reinforced epoxy laminate sheets, tubes, and rods. It is one of the most common materials used as an electrical insulator in the production of printed circuit boards (PCBs). The FR in FR4 stands for flame resistant, indicating that the material […]

-

Top rigid flex PCB suppliers in 2023

Posted by

–

Read more: Top rigid flex PCB suppliers in 2023

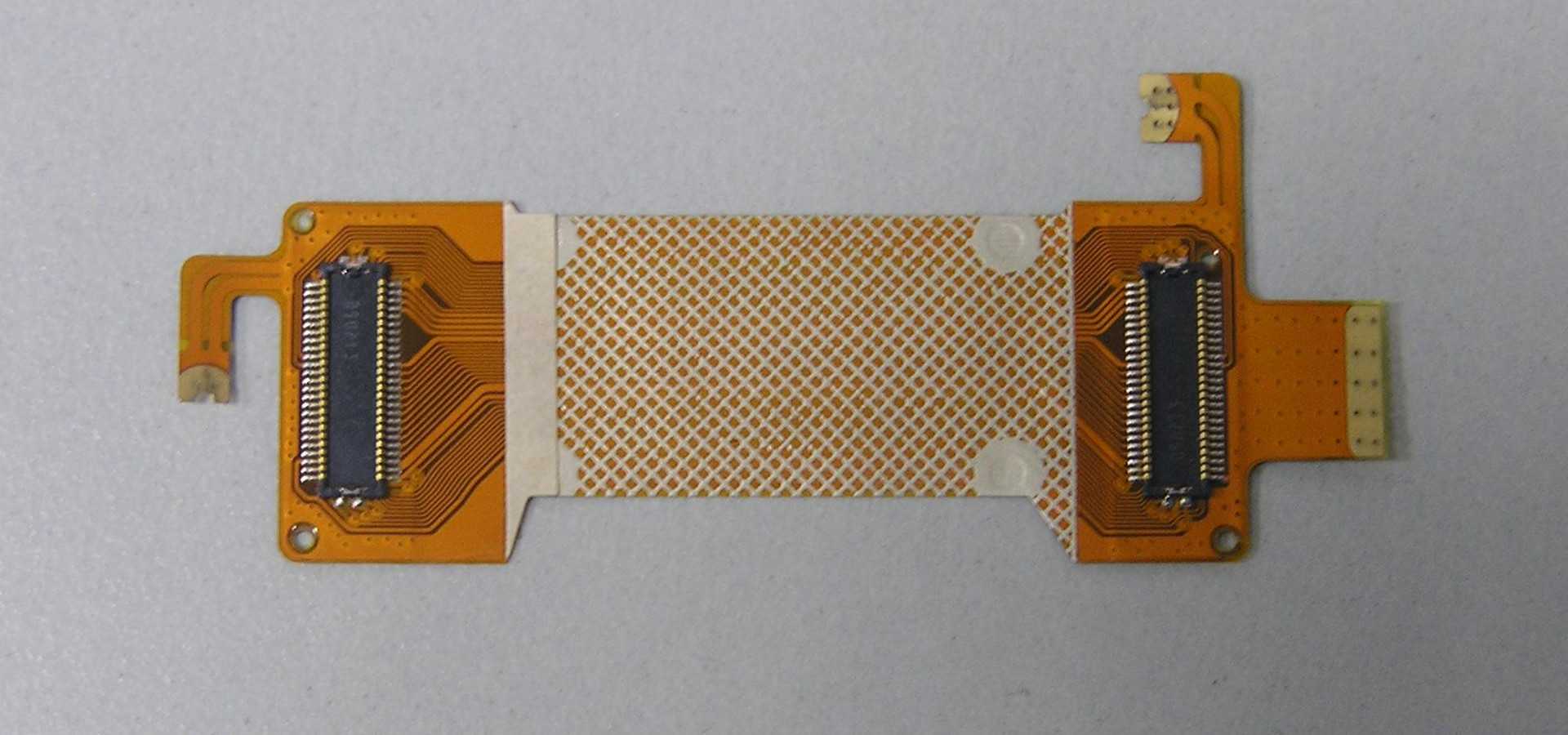

Read more: Top rigid flex PCB suppliers in 2023FQA Q1: What is a rigid flex PCB? A rigid flex PCB is a printed circuit board that consists of rigid and flexible substrates laminated together. It provides solutions for applications that require dynamics movements and mechanical complexity while maintaining high durability and reliability. The rigid sections provide structural support […]

-

The Cost of Rigid Flex PCBs

Posted by

–

Read more: The Cost of Rigid Flex PCBs

Read more: The Cost of Rigid Flex PCBsRigid flex PCBs, also known as rigid flexible printed circuit boards, combine rigid and flexible circuitry into a single component. They provide design flexibility and can optimize electronic devices by conforming to space constraints. However, rigid flex PCBs can have a higher cost than rigid PCBs. This article will examine […]

-

Flex Rigid PCB Manufacturer Selection Guide

Posted by

–

Read more: Flex Rigid PCB Manufacturer Selection Guide

Read more: Flex Rigid PCB Manufacturer Selection GuideIntroduction Flex rigid PCBs combine rigid and flexible circuitry into a single board, providing solutions for complex electronics and packaging requirements. Choosing the right flex rigid PCB manufacturer is crucial to get high-quality boards that meet design specifications. This guide covers key considerations when selecting a flex rigid PCB manufacturer, […]

-

Designing Flexible Printed Circuit Boards

Posted by

–

Read more: Designing Flexible Printed Circuit Boards

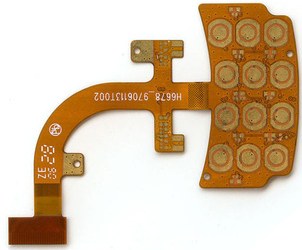

Read more: Designing Flexible Printed Circuit BoardsIntroduction Flexible printed circuit boards (PCBs) represent an important enabling technology for modern electronic devices that require flexible form factors. While rigid PCBs were historically dominant, flexible circuits are increasingly being used in consumer electronics, automotive systems, industrial equipment, and medical devices where bending, flexing, or twisting is required. Designing […]

-

The Essential Guide to PCB Assembly Flexible

Posted by

–

Read more: The Essential Guide to PCB Assembly Flexible

Read more: The Essential Guide to PCB Assembly FlexibleWhat is PCB Assembly Flexible? Printed circuit board (PCB) assembly is the process of soldering electronic components to a PCB. PCB assembly flexible refers to assembling components on flexible PCB substrates rather than traditional rigid substrates. Flexible PCBs, also known as flex circuits, are made of flexible dielectric materials such […]