ALL ABOUT FLEX PCB

-

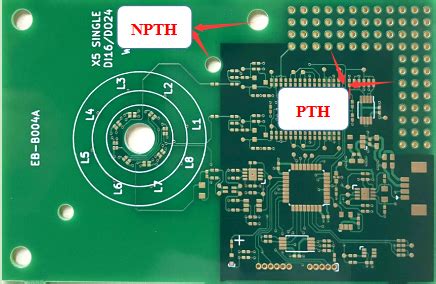

What is the finished hole size?

Posted by

–

Read more: What is the finished hole size?

Read more: What is the finished hole size?Factors Affecting Finished Hole Size Several factors can influence the finished hole size, leading to deviations from the intended diameter. These factors include: Drill Bit Size and Tolerance The drill bit size is the primary factor that determines the finished hole size. However, drill bits are manufactured with certain tolerances, […]

-

Technical Terms and Abbreviations

Posted by

–

Read more: Technical Terms and Abbreviations

Read more: Technical Terms and AbbreviationsWhat are Technical Terms? Technical terms are words or phrases that have a specific meaning within a particular field or industry. In the context of technology, technical terms are used to describe various concepts, processes, and tools related to computers, software, hardware, and other technological devices. Examples of Technical Terms […]

-

Read more: MCPCB: Metal Core PCB for LED and Thermal Management

Read more: MCPCB: Metal Core PCB for LED and Thermal ManagementIntroduction to MCPCB Metal Core Printed Circuit Boards (MCPCBs) are a specialized type of PCB that uses a metal substrate instead of the traditional FR-4 material. The metal substrate, typically aluminum, provides excellent Thermal Conductivity, making MCPCBs ideal for applications that generate significant heat, such as high-power LED lighting and […]

-

PCB Vias Types Design Covering

Posted by

–

Read more: PCB Vias Types Design Covering

Read more: PCB Vias Types Design CoveringWhat are PCB Vias? Printed Circuit Board (PCB) vias are small holes drilled through the board to create electrical connections between different layers of a multi-layer PCB. Vias allow signals to pass from one layer to another, enabling more complex circuit designs and more efficient use of board space. They […]

-

Assembly Manufacturing Technology

Posted by

–

Read more: Assembly Manufacturing Technology

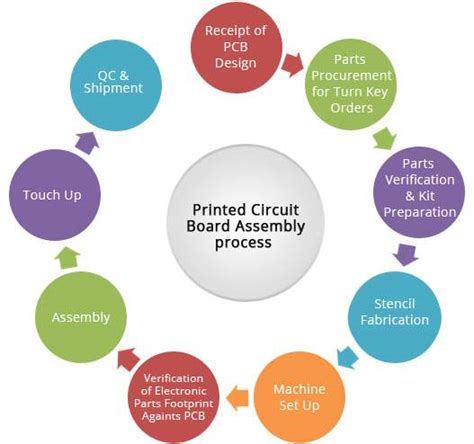

Read more: Assembly Manufacturing TechnologyHistory of Assembly Manufacturing The concept of assembly manufacturing dates back to the Industrial Revolution in the late 18th century. The introduction of interchangeable parts and the division of labor allowed for the mass production of goods, which revolutionized the manufacturing industry. In the early 20th century, the automotive industry […]

-

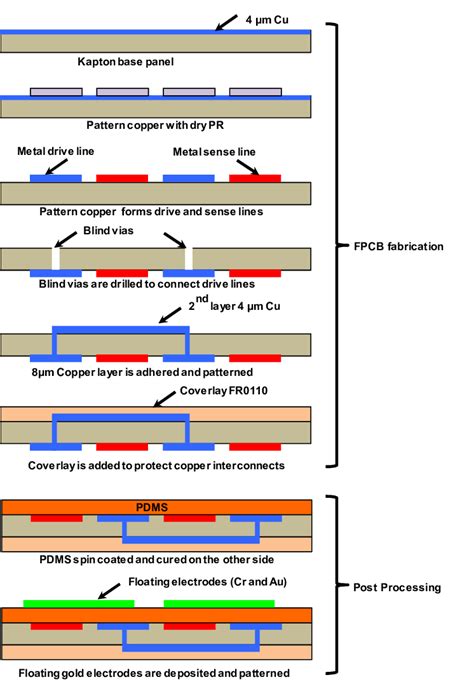

Read more: Flexible PCB Manufacturing Process: How to Fabricate FPC

Read more: Flexible PCB Manufacturing Process: How to Fabricate FPCWhat is a Flexible PCB? A flexible PCB, also known as an FPC, is a type of printed circuit board that consists of a thin, flexible substrate made of materials such as polyimide or polyester. These substrates are laminated with conductive copper traces, allowing for electrical connectivity between components. FPCs […]

-

Read more: 8 Types of PCB vias – A Complete Guide of PCB Vias

Read more: 8 Types of PCB vias – A Complete Guide of PCB ViasIntroduction to PCB Vias Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for interconnecting various electronic components. One crucial aspect of PCB design is the use of vias, which are conductive pathways that allow electrical signals to pass through different layers of the board. In […]

-

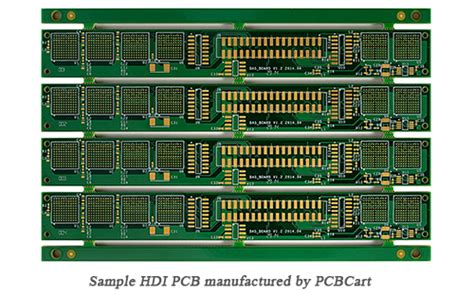

Read more: What is an HDI PCB? Its Structure and Manufacturing

Read more: What is an HDI PCB? Its Structure and ManufacturingIntroduction to HDI PCBs High Density Interconnect (HDI) Printed Circuit Boards (PCBs) are advanced circuit boards that offer higher component density and improved electrical performance compared to traditional PCBs. HDI PCBs are characterized by their fine line widths, small via sizes, and high layer counts, enabling the miniaturization of electronic […]

-

Solder Paste Something You Need to Know

Posted by

–

Read more: Solder Paste Something You Need to Know

Read more: Solder Paste Something You Need to KnowWhat is Solder Paste and Why is it Essential? Solder paste is a crucial component in the world of electronics manufacturing. It is a mixture of tiny solder particles suspended in a flux medium, which is applied to printed circuit boards (PCBs) before surface mount components are placed. The paste […]

-

Tolerances on Printed Circuit Boards

Posted by

–

Read more: Tolerances on Printed Circuit Boards

Read more: Tolerances on Printed Circuit BoardsUnderstanding PCB Tolerances and Their Importance Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing a platform for components to be mounted and interconnected. The performance and reliability of these devices heavily depend on the precision and accuracy of the PCB manufacturing process. This is where PCB […]