ALL ABOUT FLEX PCB

-

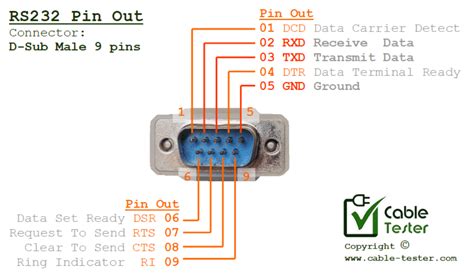

Regal ABS serial data circuit diagram and table

Posted by

–

Read more: Regal ABS serial data circuit diagram and table

Read more: Regal ABS serial data circuit diagram and tableIntroduction to Regal ABS Serial Data Circuit The Regal ABS (Anti-lock Braking System) is a critical safety feature found in modern vehicles. It helps prevent the wheels from locking up during sudden or heavy braking, allowing the driver to maintain steering control and reduce stopping distances. The Regal ABS system […]

-

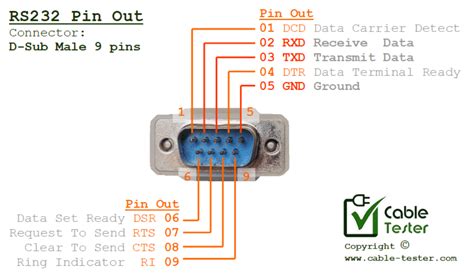

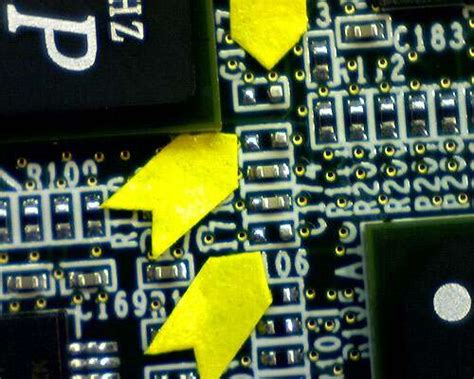

High speed PCB layout topology

Posted by

–

Read more: High speed PCB layout topology

Read more: High speed PCB layout topologyIntroduction to PCB Topology for High Speed Designs Printed circuit board (PCB) layout topology is critical for high speed electronic designs. As signal speeds and frequencies increase, the physical layout and routing of traces, planes, and components on the PCB becomes increasingly important to maintain signal integrity, minimize crosstalk and […]

-

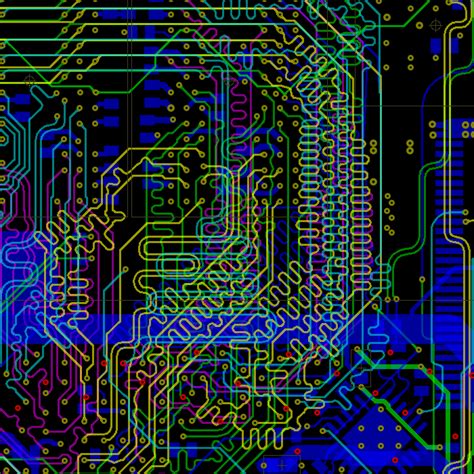

Ultraviolet Lasers In PCB Manufacturing

Posted by

–

Read more: Ultraviolet Lasers In PCB Manufacturing

Read more: Ultraviolet Lasers In PCB ManufacturingIntroduction to PCB-UV-Lasers Printed Circuit Boards (PCBs) are the backbone of modern electronics, found in virtually every electronic device we use today. The manufacturing process of PCBs has evolved significantly over the years, with new technologies emerging to improve efficiency, precision, and quality. One such technology is the use of […]

-

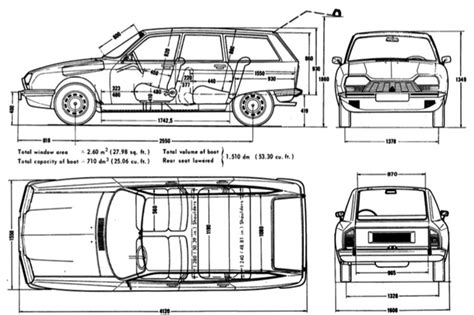

Citroen TU3F2K engine schematics

Posted by

–

Read more: Citroen TU3F2K engine schematics

Read more: Citroen TU3F2K engine schematicsIntroduction to the Citroen TU3F2K Engine The Citroen TU3F2K is a four-cylinder, inline gasoline engine that has been widely used in various Citroen models, including the Saxo, 106, and C3. This engine is known for its reliability, fuel efficiency, and compact size, making it a popular choice among car enthusiasts […]

-

Read more: The question about magnetic tape erase record circuit

Read more: The question about magnetic tape erase record circuitWhat is Magnetic tape erase? Magnetic tape erase is the process of removing previously recorded data from a magnetic tape. This is done by exposing the tape to a strong magnetic field, which effectively scrambles the magnetic particles on the tape, erasing any previously recorded information. Magnetic tape has been […]

-

PCB design of DFM some matters needing attention

Posted by

–

Read more: PCB design of DFM some matters needing attention

Read more: PCB design of DFM some matters needing attentionWhat is DFM in PCB Design? DFM, which stands for “Design for Manufacturability”, is a crucial principle in PCB design that aims to optimize the design process to ensure the manufacturability, reliability, and cost-effectiveness of the end product. By considering DFM guidelines during the design phase, engineers can avoid potential […]

-

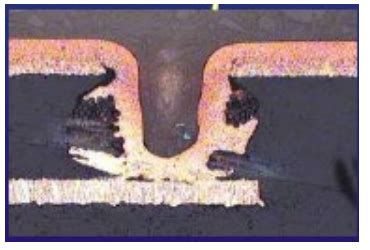

Selective Soldering

Posted by

–

Read more: Selective Soldering

Read more: Selective SolderingWhat is Selective Soldering? Selective soldering, also known as Selsoldering, is a process used in electronics manufacturing to solder specific components onto printed circuit boards (PCBs). Unlike wave soldering, which solders all components simultaneously, selective soldering targets individual components or groups of components, allowing for greater precision and flexibility in […]

-

Read more: IPC-A-600 Acceptability of Printed Boards: Classes

Read more: IPC-A-600 Acceptability of Printed Boards: ClassesIntroduction to IPC-A-600 Standards IPC-A-600 is the industry standard for establishing acceptability requirements for printed circuit boards (PCBs). Developed by the Association Connecting Electronics Industries (IPC), this standard provides visual quality acceptability requirements and illustrations for PCBs. It covers various aspects of PCB manufacturing, including materials, workmanship, solderability, and surface […]

-

Blind and Buried Vias

Posted by

–

Read more: Blind and Buried Vias

Read more: Blind and Buried ViasWhat are Blind-Buried-Vias? Blind and buried vias are two types of interconnects used in printed circuit board (PCB) design. These vias provide electrical connections between different layers of a multi-layer PCB, allowing for more complex and compact designs. Unlike through-hole vias, which span the entire thickness of the board, blind […]

-

What is Pad to Pad (PP)?

Posted by

–

Read more: What is Pad to Pad (PP)?

Read more: What is Pad to Pad (PP)?Why is Pad to Pad Spacing Important? Pad-to-Pad spacing plays a crucial role in several aspects of PCB design and manufacturing: 1. Component Placement The pad-to-pad distance directly affects the placement of components on the PCB. It determines how closely components can be placed next to each other without causing […]