Introduction

Printed circuit boards (PCBs) play a critical role in electronics, providing the foundation for mounting and interconnecting electronic components. While historically much PCB fabrication has shifted overseas, there are still many strong domestic PCB manufacturers meeting the needs of American engineers and companies. This article explores the landscape of PCB manufacturing in the USA, examining the capabilities and services offered by a range of providers catering to different applications and volumes.

Overview of USA PCB Manufacturing

PCB manufacturing began in the United States in the 1950s to meet early electronics demands. Over time, much fabrication moved offshore to take advantage of lower labor costs and high volume economies of scale. However, the USA retains a robust PCB manufacturing base serving key niches.

Advantages of domestic PCB production include:

- Faster turnaround on prototype and low volume orders

- Better communication and customer service

- Protection of intellectual property

- Avoidance of long distance shipping delays

- Ability to handle specialized or challenging requirements

- Quality and consistency for high-reliability and complex boards

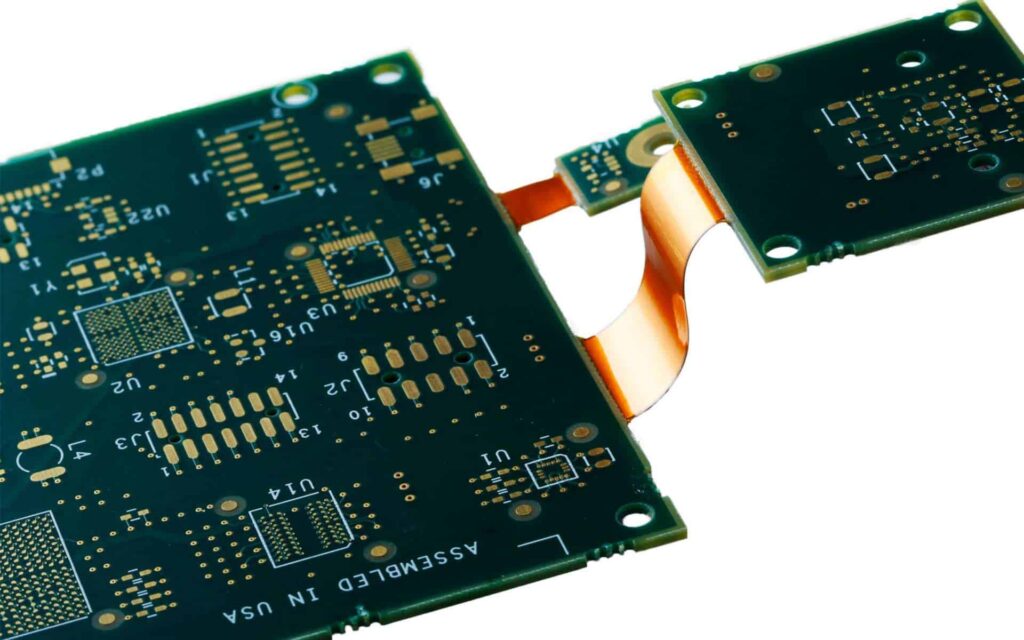

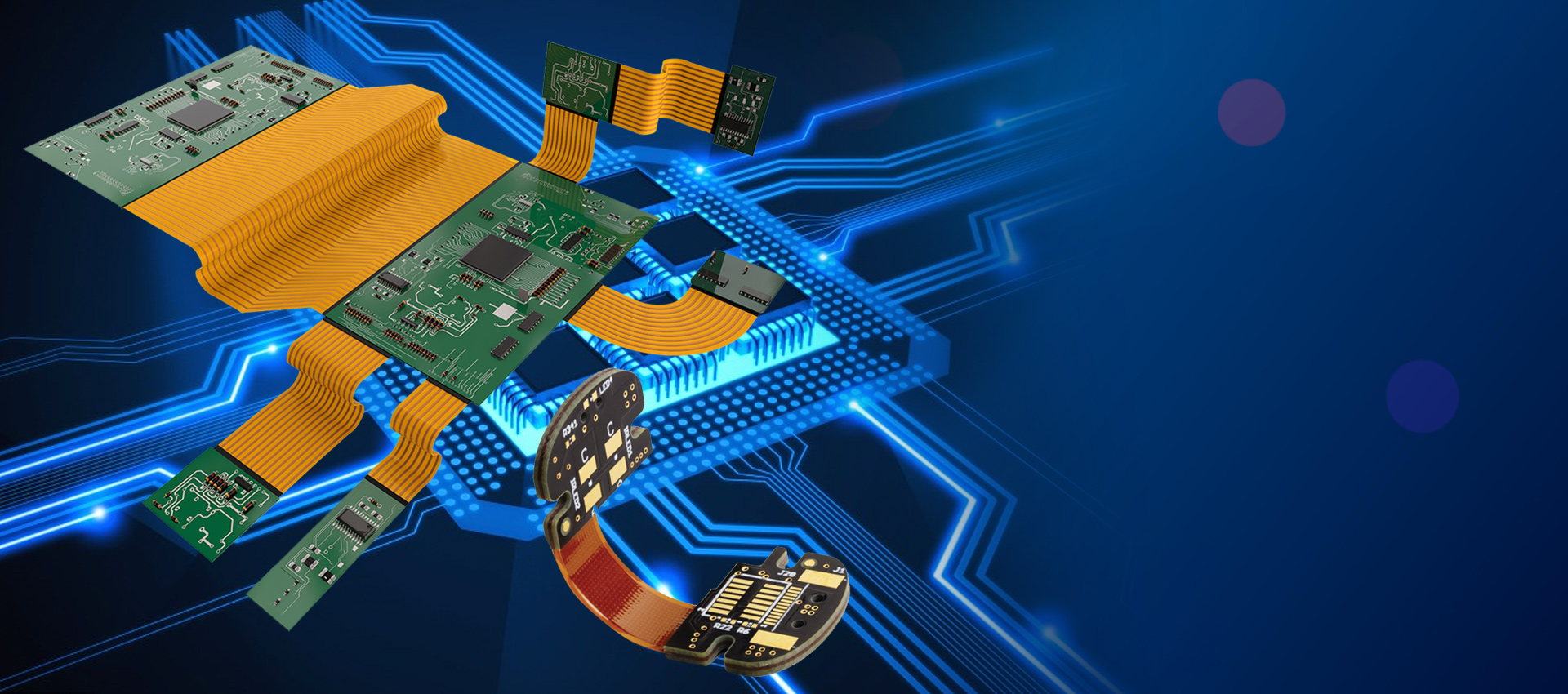

USA PCB suppliers offer the full range of rigid, flex, rigid-flex, and specialty circuit board fabrication. Both quickturn protoype runs and higher volume production orders can be fulfilled domestically.

For defense, aerospace, medical, and other quality-critical applications, North American sourcing is often mandated. The established infrastructure and expertise in American PCB fabrication facilities is well suited to handle these demanding technical needs.

Major USA PCB Manufacturers

Several large PCB fabricators with multiple facilities in the United States service high volume production orders. These domestic manufacturers offer scale to optimize costs while providing proximity and quality:

| Company | Headquarters | Facilities |

|---|---|---|

| TTM Technologies | Costa Mesa, CA | Chippewa Falls, WI<br>Dallas, TX<br>Logan, UT<br>Phoenix, AZ<br>Silicon Valley, CA |

| Sanmina Corporation | San Jose, CA | Colville, WA<br>Huntsville, AL |

| Flex | Santa Ana, CA | Plymouth, MN<br>Fremont, CA |

| Benchmark Electronics | Tempe, AZ | Hudson, NH<br>Moorpark, CA<br>Mexicali, Mexico (US border) |

| Plexus | Neenah, WI | Westminster, CO<br>Raleigh, NC<br>Tijuana, Mexico (US border) |

These large companies leverage multiple domestic plants to provide scale, redundancy, and geographic diversity when fulfilling high quantity PCB requirements for major OEMs and contract manufacturers.

Quickturn Prototype PCB Services

While offshore facilities focus primarily on high volume fabrication, the fast turnaround capabilities of American PCB shops make them ideal for prototyping and new product introduction. When rapid iterations and short lead times are critical, quickturn prototype services available domestically offer advantages.

Some leading USA PCB manufacturers specializing in quickturn fabrication include:

| Company | Location | Turnaround Time |

|---|---|---|

| Advanced Circuits | Aurora, CO | 24 hours |

| Sunstone Circuits | Mulino, OR | 24-48 hours |

| Aisler | Santa Clara, CA | 3-5 days |

| OSH Park | Lake Oswego, OR | 3-5 days |

| Epectec | Albuquerque, NM | 4-5 days |

| Voltera | Ontario, Canada | 5-10 days |

Rapid quote and ordering systems combined with optimized American manufacturing allows these PCB shops to deliver finished boards for prototyping in as fast as 24 hours when required.

Domestic facilities are better equipped to provide this degree of quickturn service versus overseas options bound by extended shipping times.

Small Batch PCB Production

For product development beyond initial prototyping but not yet requiring mass production, small batch PCB services available locally facilitate this transition. Smaller USA PCB shops provide lower volume fabrication ideal for intermediate builds and testing.

Typical characteristics of USA small batch PCB production:

- Volumes from ~25 to 1,000 boards

- Moderate lead times around ~7-15 days

- Smooth transfer to longer domestic or offshore high volume production

- Cost effective on these middle volume levels

- High quality for pre-production verification builds

- Flexibility for design modifications

Some USA PCB manufacturers catering to small batch orders include:

- 4pcb

- Royal Circuits

- AP Circuits

- Pad2Pad

- ExpressPCB

For low/middle volume fabrication needed in new product development, these domestic PCB providers deliver better pricing than quickturns but faster lead times than high volume overseas production.

Specialized and Prototyping Services

In addition to traditional board fabrication, there are PCB manufacturers in the USA offering specialized services ideal for more complex or demanding applications. These value-added capabilities facilitate overcoming technical challenges and getting innovative product designs to market.

Some examples include:

Advanced Assembly

- Full PCB assembly and box build services

- Component procurement – Design, assembly, and test offered as integrated solution

Defense/Aerospace

- ITAR-compliant fabrication facilities secured for defense work

- Rigorous quality control to meet military and avionics standards

Design Support

- PCB design reviews to improve manufacturability

- DFM analysis before manufacturing

- Quickturn engineering prototyping services

Special Materials

- Capability with Rogers, Polyimide, Arlon and other advanced laminates

- Large panel processing for reduced costs

- Flex and rigid-flex PCB fabrication skills

Access to these specialized offerings provides a key benefit of partnering with capable USA PCB manufacturers versus relying solely on offshore options.

Factors in Selecting a USA PCB Manufacturer

Choosing the right domestic PCB supplier involves balancing factors including:

Technical Capability

- Equipment and processes to meet application requirements (layer count, tolerances, etc.)

- Materials supported like high frequency laminates

- Available special services like assembly, rapid prototyping, etc.

Quality

- Consistent processes and controls to ensure defect-free product

- Testing capabilities

- Industry certifications

Cost

- Pricing model – low volume prototypes vs. high quantity production

- Value relative to product application needs

- Feasibility for project budget

Lead Time

- Turnaround time acceptable for project schedule

- On-time delivery history

Customer Service

- Responsiveness to discuss needs and ensure satisfaction

- Ease of doing business throughout the process

Selecting a PCB company balancing these aspects provides the greatest assurance of successful procurement.

Should You Use a PCB Manufacturer in the USA or Offshore?

Determining whether to source PCBs domestically or from overseas depends on balancing factors around cost, quality, lead time, and capabilities.

Reasons to choose a USA PCB manufacturer:

- Fast turnaround on lower volume or quickturn boards

- Complex, high reliability product needs demanding strict quality control

- Advanced or specialized technological capabilities required

- Need for close collaboration, design reviews, and engineering partnership

- Concerns over protection of intellectual property

- Import/export regulations preclude offshore sourcing

Reasons to choose an overseas PCB manufacturer:

- Requirement for high volume mass production fabrication

- Standardized, non-complex board designs where quality is less critical

- Very cost-driven project with minimal budget

- Early stages of product development with uncertainty requiring design tweaks

- Long project schedule allowing for extended lead times

There are excellent PCB manufacturers worldwide. The ideal partner balances cost, delivery, quality, and capabilities based on specific project needs and tradeoffs.

Conclusion

While the geography of PCB manufacturing has expanded globally, North America retains a strong base of domestic PCB fabrication capabilities. The quickturn, small batch, and specialized services offered by USA PCB companies make them an attractive option for meeting the needs of many electronics designers and engineers. Partnering with the right manufacturer domestically provides quality, communication, and speed benefits over importation from offshore facilities in the appropriate situations. Carefully weighing the factors around requirements, cost, lead time, and technical capabilities is necessary when deciding where to produce printed circuit boards for a project. With diligent selection, American PCB manufacturers can deliver a winning hardware foundation for innovative electronic products.

Frequently Asked Questions about USA PCB Manufacturing

What are typical lead times for USA made PCBs?

Lead times from USA PCB factories depend heavily on quantities and layer counts:

- Quickturn boards – 24-48 hours

- Simple 2-4 layer prototyping – 3-7 days

- Multilayer production boards – 1-4 weeks

For offshore factories, lead times generally range from 2-6 weeks but can be longer.

What PCB capabilities are commonly available from US manufacturers?

Most USA PCB suppliers offer a full range of rigid, rigid-flex, flex, and specialty board fabrication. Capabilities typically include:

- Layer counts from single to 20+ layers

- Line/space down to 3/3 mils

- Quickturn, low-mid volume, and higher volume production

- Solder mask, ENIG/Immersion tin plating, controlled impedance

- Testing/inspection services

- Design support and DFM analysis

What volumes make sense for domestic vs. overseas PCB production?

As an approximate guideline based on cost:

- Prototyping & low volume – <500 units use USA

- Medium volumes – 500-5,000 evaluate USA vs. offshore

- High volume – >5,000 favor overseas

But technical factors may justify USA production at higher quantities for quality-critical boards.

How much more expensive is USA vs. offshore PCB manufacturing?

For low volume boards, US pricing is comparable or only marginally higher than offshore. At production quantities, offshore factories can be 25-50% cheaper for high volume commodity boards without complex requirements. More advanced boards minimize the cost differential.

Are there any PCB manufacturers left in the USA?

Yes, a wide range of PCB manufacturers with facilities across the USA continues to thrive serving domestic needs. While offshore production handles high volume commodity work, American shops remain strong in early stage development through small-medium batch production where responsiveness provides value.

Conclusion

Despite outsourcing trends, capable PCB manufacturers steadfastly operate across America. Their unique advantages for prototyping, flexible services, and navigating complex requirements drive value for U.S. product developers. With careful partner selection, engineers can access world-class domestic PCB fabrication to meet technical needs and bring innovative electronic products to fruition.

Leave a Reply