What is Rogers Material PCB?

Rogers PCB refers to printed circuit boards that are manufactured using materials from Rogers Corporation, a leading manufacturer of high-frequency and high-speed PCB materials. Rogers materials are known for their excellent electrical properties, low dielectric loss, and high thermal conductivity, making them ideal for high-frequency and high-speed applications.

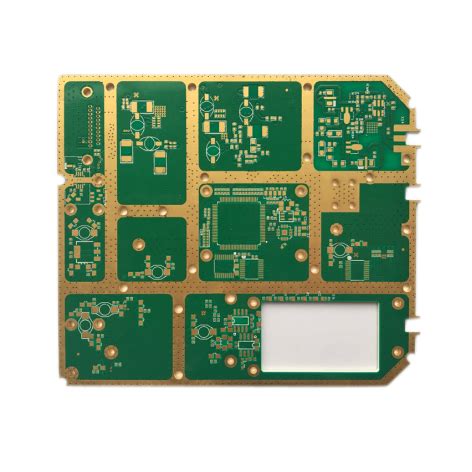

RAYPCB is a professional PCB manufacturer that specializes in producing high-quality Rogers PCB for various industries, including telecommunications, aerospace, defense, and medical devices. With state-of-the-art manufacturing facilities and a team of experienced engineers, RAYPCB can provide customized Rogers PCB solutions to meet the specific requirements of their clients.

Advantages of Rogers PCB

1. Low Dielectric Loss

One of the main advantages of Rogers PCB is its low dielectric loss. Dielectric loss refers to the energy lost as heat when an alternating electric field is applied to a dielectric material. In high-frequency applications, dielectric loss can significantly impact signal integrity and system performance.

Rogers materials have a very low dielectric loss, which means that they can maintain signal integrity even at high frequencies. This makes Rogers PCB ideal for applications such as 5G communications, radar systems, and satellite communications.

2. High Thermal Conductivity

Another advantage of Rogers PCB is its high thermal conductivity. Thermal conductivity refers to the ability of a material to conduct heat. In high-power applications, heat generation can be a significant problem, leading to reduced performance and reliability.

Rogers materials have a high thermal conductivity, which means that they can effectively dissipate heat away from critical components. This helps to maintain system performance and reliability, even under demanding conditions.

3. Excellent Mechanical Properties

Rogers PCB also has excellent mechanical properties, including high strength and dimensional stability. This makes them ideal for applications where mechanical stress and vibration are a concern, such as in aerospace and defense systems.

Rogers materials are also resistant to moisture and chemicals, which helps to ensure long-term reliability and performance.

Rogers PCB Materials

Rogers Corporation offers a wide range of PCB materials, each with its own unique properties and characteristics. Some of the most popular Rogers PCB materials include:

1. RO4000 Series

The RO4000 series is a popular choice for high-frequency applications, such as in telecommunications and radar systems. It offers a low dielectric constant and low loss tangent, making it ideal for applications where signal integrity is critical.

| Material | Dielectric Constant | Dissipation Factor | Thermal Conductivity (W/m/K) |

|---|---|---|---|

| RO4003C | 3.38 | 0.0027 | 0.71 |

| RO4350B | 3.48 | 0.0037 | 0.69 |

| RO4360G2 | 6.15 | 0.0038 | 0.66 |

2. RT/duroid 5870/5880

The RT/duroid 5870/5880 series is another popular choice for high-frequency applications. It offers a low dielectric constant and low loss tangent, as well as excellent thermal conductivity.

| Material | Dielectric Constant | Dissipation Factor | Thermal Conductivity (W/m/K) |

|---|---|---|---|

| RT/duroid 5870 | 2.33 | 0.0012 | 0.22 |

| RT/duroid 5880 | 2.20 | 0.0009 | 0.20 |

3. RO3000 Series

The RO3000 series is a cost-effective alternative to the RO4000 series, offering similar performance at a lower cost. It is often used in commercial and consumer electronics applications.

| Material | Dielectric Constant | Dissipation Factor | Thermal Conductivity (W/m/K) |

|---|---|---|---|

| RO3003 | 3.00 | 0.0013 | 0.50 |

| RO3006 | 6.15 | 0.0020 | 0.61 |

| RO3010 | 10.20 | 0.0023 | 0.66 |

RAYPCB’s Rogers PCB Manufacturing Capabilities

RAYPCB has extensive experience in manufacturing Rogers PCB for a wide range of applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing them to produce high-quality Rogers PCB with tight tolerances and high reliability.

Some of RAYPCB’s key manufacturing capabilities include:

1. Multi-Layer PCB

RAYPCB can produce multi-layer Rogers PCB with up to 28 layers, allowing for complex designs and high-density interconnects. They use advanced lamination techniques to ensure excellent layer-to-layer registration and high reliability.

2. Controlled Impedance

RAYPCB can produce Rogers PCB with controlled impedance, ensuring that the impedance of the transmission lines matches the desired value. This is critical for high-frequency applications where impedance matching is essential for signal integrity.

3. Fine Pitch

RAYPCB can produce Rogers PCB with fine pitch features, such as small vias and traces. This allows for higher density designs and improved signal integrity.

4. Blind and Buried Vias

RAYPCB can produce Rogers PCB with blind and buried vias, allowing for more complex routing and improved signal integrity. Blind vias connect an outer layer to an inner layer, while buried vias connect two inner layers.

5. Copper Thickness

RAYPCB can produce Rogers PCB with a wide range of copper thicknesses, from 0.5 oz to 6 oz. This allows for customized designs that meet specific electrical and thermal requirements.

Applications of Rogers PCB

Rogers PCB is used in a wide range of applications, including:

1. Telecommunications

Rogers PCB is widely used in telecommunications applications, such as 5G base stations, antennas, and filters. The low dielectric loss and high thermal conductivity of Rogers materials make them ideal for these high-frequency applications.

2. Aerospace and Defense

Rogers PCB is also used in aerospace and defense applications, such as radar systems, satellite communications, and avionics. The excellent mechanical properties and chemical resistance of Rogers materials make them ideal for these demanding applications.

3. Medical Devices

Rogers PCB is used in medical devices, such as MRI machines and other diagnostic equipment. The low dielectric loss and high thermal conductivity of Rogers materials help to ensure high-quality imaging and reliable performance.

4. Automotive Electronics

Rogers PCB is used in automotive electronics, such as advanced driver assistance systems (ADAS) and autonomous driving systems. The high-frequency capabilities and reliability of Rogers materials make them ideal for these safety-critical applications.

FAQ

1. What is the lead time for Rogers PCB at RAYPCB?

The lead time for Rogers PCB at RAYPCB varies depending on the complexity of the design and the quantity ordered. Typically, lead times range from 2-3 weeks for standard designs to 4-6 weeks for more complex designs.

2. What is the minimum order quantity for Rogers PCB at RAYPCB?

The minimum order quantity for Rogers PCB at RAYPCB varies depending on the specific material and design requirements. For standard materials and designs, the minimum order quantity is typically 5-10 pieces. For custom materials and designs, the minimum order quantity may be higher.

3. Can RAYPCB provide design support for Rogers PCB?

Yes, RAYPCB has a team of experienced engineers who can provide design support for Rogers PCB. They can work with customers to optimize designs for manufacturability, reliability, and performance.

4. What certifications does RAYPCB have for Rogers PCB manufacturing?

RAYPCB is ISO 9001:2015 and IATF 16949:2016 certified for quality management systems. They are also UL and RoHS compliant for safety and environmental standards.

5. How does RAYPCB ensure the quality of their Rogers PCB?

RAYPCB has a comprehensive quality control system in place to ensure the quality of their Rogers PCB. This includes incoming material inspection, in-process inspection, and final inspection. They also use advanced testing equipment, such as X-ray and impedance analyzers, to verify the quality of the finished product.

Conclusion

Rogers PCB is a high-performance material that offers excellent electrical, thermal, and mechanical properties for demanding applications. RAYPCB is a leading manufacturer of Rogers PCB, with state-of-the-art manufacturing facilities and a team of experienced engineers.

Whether you are designing for telecommunications, aerospace, medical devices, or automotive electronics, RAYPCB can provide customized Rogers PCB solutions to meet your specific requirements. With their extensive manufacturing capabilities and commitment to quality, RAYPCB is the ideal partner for your Rogers PCB needs.

Leave a Reply