What is a Breadboard?

A breadboard is a reusable prototyping board used for building and testing electronic circuits without the need for soldering. It consists of a plastic board with a grid of holes, into which electronic components and jumper wires can be inserted to create temporary connections.

Advantages of Breadboards

- Quick and easy prototyping: Breadboards allow you to quickly assemble and modify circuits without soldering, making it easy to experiment and iterate on your designs.

- Reusability: Components can be easily removed and reused in other projects, saving time and money.

- Beginner-friendly: Breadboards are an excellent choice for those new to electronics, as they provide a low-risk environment for learning and experimentation.

Disadvantages of Breadboards

- Limited complexity: As circuits become more complex, breadboards can become cluttered and difficult to manage, leading to errors and signal integrity issues.

- Lack of durability: Breadboards are not suitable for permanent installations or rough handling, as components can easily become dislodged.

- No support for high frequencies: The long jumper wires and lack of proper shielding make breadboards unsuitable for high-frequency circuits or sensitive analog designs.

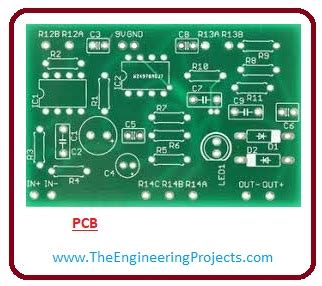

What is a PCB?

A printed circuit board (PCB) is a custom-designed board that provides a permanent and reliable way to connect electronic components. PCBs are made by etching conductive traces onto a non-conductive substrate, such as fiberglass or plastic, and then soldering components onto the board.

Advantages of PCBs

- Durability and reliability: PCBs offer a sturdy and permanent solution for electronic circuits, making them suitable for long-term use and harsh environments.

- Compact and space-efficient: PCBs can be designed to minimize space and optimize component placement, resulting in smaller and more efficient devices.

- High-frequency performance: The short traces and proper shielding of PCBs make them suitable for high-frequency circuits and sensitive analog designs.

- Mass production: Once a PCB design is finalized, it can be easily replicated for mass production, reducing costs and increasing consistency.

Disadvantages of PCBs

- Higher initial costs: Designing and manufacturing PCBs require specialized software, tools, and services, which can be more expensive than using breadboards, especially for small-scale projects.

- Longer development time: Creating a PCB involves designing, fabricating, and assembling the board, which can take significantly longer than prototyping with breadboards.

- Limited flexibility: Once a PCB is manufactured, making changes to the circuit can be difficult and costly, often requiring a new board to be designed and produced.

Comparing Breadboards and PCBs

| Feature | Breadboard | PCB |

|---|---|---|

| Prototyping speed | Fast | Slow |

| Reusability | High | Low |

| Durability | Low | High |

| Complexity support | Low | High |

| High-frequency performance | Poor | Good |

| Cost (small-scale) | Low | High |

| Cost (large-scale) | High | Low |

| Development time | Short | Long |

| Flexibility | High | Low |

As you can see, breadboards and PCBs have their own strengths and weaknesses. Breadboards excel at rapid prototyping and experimentation, while PCBs offer durability, reliability, and better performance for complex and high-frequency circuits. The choice between the two depends on your specific project requirements, budget, and timeline.

When to Use a Breadboard

Breadboards are the ideal choice when:

- You’re learning electronics or teaching others: Breadboards provide a safe and easy way to explore electronic concepts and build simple circuits.

- You need to quickly test an idea or prototype a circuit: Breadboards allow you to assemble and modify circuits rapidly, without the need for soldering or custom PCB design.

- You’re working on a small-scale, low-complexity project: Breadboards are perfect for simple projects that don’t require high performance or durability.

- You have a limited budget: Breadboards are inexpensive and reusable, making them a cost-effective choice for small-scale projects or personal use.

When to Use a PCB

PCBs are the preferred choice when:

- You’re working on a complex or high-performance circuit: PCBs offer better signal integrity, shielding, and component placement for complex designs and high-frequency circuits.

- You need a durable and reliable solution: PCBs are designed to withstand harsh environments and long-term use, making them ideal for finished products or permanent installations.

- You’re designing a compact or space-constrained device: PCBs can be designed to minimize space and optimize component placement, resulting in smaller and more efficient devices.

- You plan to mass-produce your design: Once a PCB design is finalized, it can be easily replicated for mass production, reducing costs and ensuring consistency across units.

Combining Breadboards and PCBs

In some cases, it may be beneficial to use both breadboards and PCBs in your project development process. You can start by prototyping your circuit on a breadboard, allowing you to quickly test and refine your design. Once you have a working prototype, you can then transition to a PCB for a more permanent and reliable solution.

This approach combines the best of both worlds: the flexibility and speed of breadboards for prototyping, and the durability and performance of PCBs for the final product. It also helps minimize the risk of errors and redesigns, as you can verify your circuit on a breadboard before committing to a PCB.

FAQ

- Can I use a breadboard for a permanent installation?

-

While it is possible to use a breadboard for a permanent installation, it is not recommended. Breadboards are designed for temporary prototyping and lack the durability and reliability needed for long-term use or harsh environments. For permanent installations, it is best to use a PCB.

-

Are PCBs more expensive than breadboards?

-

The cost comparison between PCBs and breadboards depends on the scale of your project. For small-scale or one-off projects, PCBs can be more expensive due to the initial design and manufacturing costs. However, for large-scale production, PCBs become more cost-effective as the per-unit cost decreases with volume.

-

Can I convert my breadboard circuit to a PCB?

-

Yes, you can convert your breadboard circuit to a PCB. Once you have a working prototype on a breadboard, you can use PCB design software to create a schematic and layout for your circuit. This design can then be sent to a PCB manufacturer for fabrication and assembly.

-

Do I need to know how to solder to work with PCBs?

-

While soldering is necessary for assembling components onto a PCB, you don’t necessarily need to know how to solder to work with PCBs. Many PCB manufacturers offer assembly services, where they will solder the components onto the board for you based on your design files.

-

Can I reuse components from a PCB?

- Reusing components from a PCB is possible but can be more difficult and time-consuming than with breadboards. Desoldering components from a PCB requires specialized tools and skills, and there is a risk of damaging the components or the board in the process. In most cases, it is easier and more cost-effective to use new components for each PCB.

Conclusion

Choosing between a breadboard and a PCB for your electronic projects depends on various factors, including your project’s complexity, durability requirements, budget, and timeline. Breadboards are ideal for quick prototyping, learning, and small-scale projects, while PCBs are better suited for complex, high-performance circuits, permanent installations, and mass production.

By understanding the strengths and weaknesses of each option, you can make an informed decision that best fits your project’s needs. In some cases, using a combination of breadboards for prototyping and PCBs for the final product can provide the best balance of flexibility, speed, and reliability.

Regardless of your choice, both breadboards and PCBs are essential tools in the world of electronics, enabling hobbyists, students, and professionals alike to bring their ideas to life and create innovative solutions to real-world problems.

Leave a Reply