What is FFC?

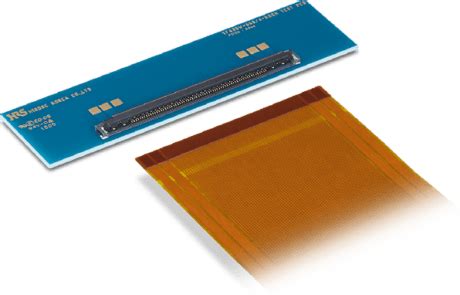

FFC, or Flexible Flat Cable, is a type of cable that consists of a flat, flexible plastic film with embedded parallel conductors. These conductors are typically made of copper or tinned copper and are evenly spaced across the width of the cable. FFCs are designed to provide a simple, lightweight, and cost-effective solution for connecting components in various electronic devices.

Characteristics of FFC

- Flat and flexible design

- Parallel conductors embedded in a plastic film

- Typically used for shorter distances and lower frequencies

- Cost-effective and easy to install

- Available in various pitches and conductor counts

What is FPC?

FPC, or Flexible Printed Circuit, is a more advanced and versatile type of flexible circuit. Unlike FFCs, which have a simple construction with parallel conductors, FPCs feature a complex layout of copper traces printed on a flexible substrate. This allows for greater design flexibility, enabling the creation of intricate circuits with multiple layers and components.

Characteristics of FPC

- Complex layout of copper traces printed on a flexible substrate

- Can incorporate multiple layers and components

- Suitable for longer distances and higher frequencies

- Offers greater design flexibility and customization

- More expensive than FFCs due to their complex manufacturing process

Key Differences Between FFC and FPC

Now that we have a basic understanding of FFC and FPC, let’s dive into the main differences between the two:

Construction

The most significant difference between FFC and FPC lies in their construction. FFCs have a simple design with parallel conductors embedded in a flat, flexible plastic film. On the other hand, FPCs feature a complex layout of copper traces printed on a flexible substrate, allowing for greater design flexibility and the incorporation of multiple layers and components.

Applications

Due to their different constructions and capabilities, FFC and FPC are suited for different applications. FFCs are commonly used in applications that require simple, short-distance connections, such as:

- Connecting displays to motherboards in smartphones and tablets

- Connecting keyboards and touchpads in laptops

- Connecting various components in consumer electronics, such as digital cameras and portable audio devices

FPCs, with their advanced design and higher performance, are better suited for more demanding applications, such as:

- High-speed data transmission in aerospace and military equipment

- Medical devices that require compact and reliable connections

- Automotive electronics, including infotainment systems and sensors

- Wearable technology, where flexibility and durability are crucial

Performance

Another key difference between FFC and FPC is their performance. FFCs are generally limited to shorter distances and lower frequencies due to their simple construction. They are not suitable for high-speed data transmission or applications that require a high degree of signal integrity.

FPCs, on the other hand, can handle longer distances and higher frequencies thanks to their advanced design and the ability to incorporate shielding and other performance-enhancing features. They offer better signal integrity and can support high-speed data transmission, making them ideal for demanding applications.

Cost

The cost difference between FFC and FPC is another important factor to consider. FFCs are generally more cost-effective than FPCs due to their simpler construction and manufacturing process. They are an excellent choice for applications that require a large number of connections and where cost is a primary concern.

FPCs, with their complex design and advanced features, are more expensive to manufacture than FFCs. However, their higher cost is often justified by their superior performance and the ability to create custom designs tailored to specific applications.

Flexibility and Durability

Both FFC and FPC offer flexibility, which is essential for applications where space is limited or where the cable needs to bend and flex repeatedly. However, FPCs generally offer greater flexibility and durability compared to FFCs.

FPCs can be designed with a thinner substrate and can incorporate strain relief features, making them more resistant to damage caused by repeated flexing. They can also be reinforced with additional layers or materials to enhance their durability in harsh environments.

FFCs, while still flexible, may be more susceptible to damage from repeated bending and may have a shorter lifespan in applications that require constant flexing.

Comparison Table

| Feature | FFC | FPC |

|---|---|---|

| Construction | Parallel conductors embedded in a flat, flexible plastic film | Complex layout of copper traces printed on a flexible substrate |

| Applications | Simple, short-distance connections in consumer electronics | Demanding applications in aerospace, medical, and automotive |

| Performance | Limited to shorter distances and lower frequencies | Can handle longer distances, higher frequencies, and better signal integrity |

| Cost | More cost-effective due to simpler construction | More expensive due to complex design and advanced features |

| Flexibility | Flexible, but may be more susceptible to damage from repeated bending | Offers greater flexibility and can incorporate strain relief features |

| Durability | May have a shorter lifespan in applications with constant flexing | Can be reinforced for enhanced durability in harsh environments |

Choosing Between FFC and FPC

When deciding between FFC and FPC for your application, consider the following factors:

-

Application requirements: Assess the specific needs of your application, such as the distance between components, the required signal integrity, and the operating environment. This will help you determine whether FFC or FPC is more suitable.

-

Design complexity: If your application requires a simple, short-distance connection, FFC may be sufficient. However, if you need a more complex design with multiple layers and components, FPC is the better choice.

-

Cost considerations: Evaluate the cost implications of using FFC or FPC in your application. While FFCs are generally more cost-effective, the higher cost of FPCs may be justified if your application demands superior performance and durability.

-

Flexibility and durability: Consider the flexibility and durability requirements of your application. If your cable needs to withstand repeated bending or harsh environmental conditions, FPC may be the more suitable option.

FAQ

-

Can FFC and FPC be used interchangeably?

While FFC and FPC serve similar purposes in providing flexible connections, they are not always interchangeable. The choice between FFC and FPC depends on the specific requirements of your application, such as design complexity, performance, and cost. -

What are the typical pitches available for FFC?

FFCs are available in various pitches, with common options being 0.5mm, 1.0mm, 1.25mm, and 2.54mm. The pitch refers to the distance between the centers of adjacent conductors. -

Can FPCs incorporate components directly on the flexible substrate?

Yes, one of the advantages of FPCs is the ability to mount components directly on the flexible substrate. This allows for greater design flexibility and the creation of more compact and integrated solutions. -

How do I terminate FFC and FPC?

Both FFC and FPC can be terminated using various methods, such as zero insertion force (ZIF) connectors, low insertion force (LIF) connectors, or soldering. The choice of termination method depends on factors such as the application requirements, the available space, and the ease of assembly. -

Are there any limitations to the length of FFC and FPC?

The maximum length of FFC and FPC is limited by factors such as signal integrity, voltage drop, and electromagnetic interference (EMI). In general, FFCs are more suitable for shorter distances (up to a few meters), while FPCs can support longer distances (up to several meters) with proper design and shielding.

Conclusion

Understanding the differences between FFC and FPC is crucial when selecting the most suitable flexible circuit solution for your application. While both offer flexibility and space-saving benefits, they differ in their construction, applications, performance, cost, and durability.

FFCs are a cost-effective choice for simple, short-distance connections in consumer electronics, while FPCs are better suited for demanding applications that require advanced design, higher performance, and greater durability.

By carefully considering the specific requirements of your application and weighing the advantages and limitations of FFC and FPC, you can make an informed decision that ensures optimal performance, reliability, and cost-effectiveness in your electronic devices.

Leave a Reply