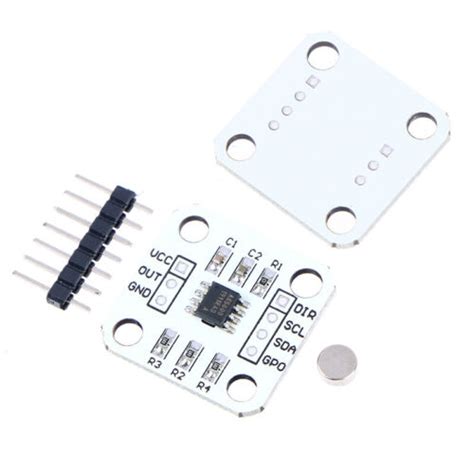

Introduction to the AS5600 Magnetic Sensor

The AS5600 is a state-of-the-art magnetic rotary position sensor developed by ams AG, a leading provider of high-performance sensor solutions. This sensor utilizes Hall effect technology to detect the angular position of a magnetic field, enabling precise and contactless measurement of rotary motion. With its 12-bit resolution, the AS5600 offers exceptional accuracy and reliability, making it an ideal choice for a wide range of applications.

Key Features of the AS5600

- 12-bit angular resolution (0.088° per step)

- Contactless sensing technology

- Wide operating voltage range (3.3V to 5V)

- Low power consumption (< 10 mA)

- High-speed I2C interface (up to 1 MHz)

- Programmable zero position and magnetic field range

- Built-in temperature compensation

- Compact package (TSSOP-16)

Working Principle of the AS5600

The AS5600 magnetic sensor operates based on the Hall effect principle, which states that a voltage difference is generated across a conductor when it is placed in a magnetic field perpendicular to the current flow. The sensor consists of a set of Hall elements arranged in a circular pattern, allowing it to detect the angular position of a rotating magnetic field.

Hall Effect Sensing

The Hall elements in the AS5600 are made of a semiconductor material, typically silicon. When a current flows through these elements in the presence of a magnetic field, a voltage difference is generated across them. The magnitude of this voltage is proportional to the strength of the magnetic field and the angle between the field and the Hall elements.

Magnetic Field Detection

The AS5600 is designed to detect the angular position of a rotating magnet placed above the sensor. The magnet generates a magnetic field that interacts with the Hall elements, causing a change in their output voltage. By measuring this voltage change, the sensor can determine the angular position of the magnet with high precision.

Signal Processing and Output

The output voltages from the Hall elements are processed by the AS5600’s internal circuitry, which includes an analog-to-digital converter (ADC) and a digital signal processor (DSP). The ADC converts the analog voltage signals into digital values, while the DSP performs various calculations and compensations to improve the accuracy and stability of the sensor’s output.

The processed data is then made available through the sensor’s I2C interface, which allows easy integration with microcontrollers and other digital systems. The AS5600 provides a 12-bit angular position value, representing the magnet’s angle with a resolution of 0.088° per step.

Benefits of Using the AS5600 Magnetic Sensor

The AS5600 offers several advantages over traditional rotary position sensing methods, such as potentiometers and optical encoders. Some of the key benefits include:

-

Contactless Sensing: The AS5600 provides contactless position sensing, eliminating the need for physical contact between the sensor and the rotating component. This reduces wear and tear, increases reliability, and extends the sensor’s lifespan.

-

High Accuracy: With its 12-bit resolution, the AS5600 offers exceptional accuracy in angular measurement. This allows for precise control and monitoring of rotary motion in various applications.

-

Low Power Consumption: The AS5600 is designed for low power operation, consuming less than 10 mA during normal operation. This makes it suitable for battery-powered and energy-efficient systems.

-

Compact Size: The sensor comes in a compact TSSOP-16 package, measuring only 6.4 mm x 5.0 mm x 1.2 mm. This small footprint enables easy integration into space-constrained designs.

-

Programmability: The AS5600 allows users to program the zero position and magnetic field range, providing flexibility in system design and calibration.

-

Temperature Compensation: The sensor features built-in temperature compensation, ensuring stable and accurate performance over a wide temperature range.

Applications of the AS5600 Magnetic Sensor

The AS5600 finds applications in various fields where precise rotary position sensing is required. Some of the common applications include:

-

Industrial Automation: The sensor can be used in robotics, CNC machines, and other automated systems for precise angular position control and feedback.

-

Automotive Systems: The AS5600 is suitable for automotive applications such as throttle position sensing, steering angle measurement, and pedal position detection.

-

Medical Devices: The sensor’s contactless and high-precision capabilities make it ideal for medical equipment, such as robotic surgical tools and rehabilitation devices.

-

Consumer Electronics: The AS5600 can be used in consumer products like joysticks, rotary encoders, and digital potentiometers for high-resolution angular sensing.

-

Aerospace and Defense: The sensor’s robustness and reliability make it suitable for aerospace and defense applications, such as gimbal systems and antenna positioning.

Implementing the AS5600 Magnetic Sensor

Integrating the AS5600 into a system involves several steps, including hardware connection, software configuration, and calibration. Here’s a general overview of the implementation process:

Hardware Connection

The AS5600 communicates via the I2C protocol, requiring only four connections to the host microcontroller:

- VDD: Power supply (3.3V to 5V)

- GND: Ground

- SDA: I2C serial data line

- SCL: I2C serial clock line

The sensor also requires a rotating magnet to be placed above it for angular position sensing. The magnet should be positioned at a suitable distance from the sensor, typically between 1 mm and 3 mm, to ensure optimal performance.

Software Configuration

To communicate with the AS5600, the host microcontroller must be programmed to support the I2C protocol. The sensor’s I2C address is fixed at 0x36, and it supports standard (100 kHz) and fast (400 kHz) I2C modes.

The AS5600 provides several configuration registers that allow users to customize its behavior, such as setting the zero position, adjusting the magnetic field range, and enabling/disabling specific features. These registers can be accessed and modified through I2C commands.

Calibration

To ensure accurate angular position measurements, the AS5600 must be calibrated after installation. The calibration process involves determining the magnet’s zero position and the sensor’s output range.

The zero position can be set by placing the magnet at the desired reference angle and writing the corresponding value to the sensor’s zero position register. The output range can be adjusted by setting the appropriate magnetic field range in the configuration register.

Performance Characteristics

The AS5600 offers excellent performance in terms of accuracy, resolution, and speed. Here are some key performance characteristics:

| Parameter | Value |

|---|---|

| Resolution | 12 bits (0.088° per step) |

| Accuracy | ± 1.4° (full-scale) |

| Linearity | ± 0.5% (full-scale) |

| Update Rate | Up to 1 kHz |

| Operating Temperature | -40°C to +125°C |

These performance figures demonstrate the AS5600’s suitability for high-precision rotary position sensing applications, where accuracy and reliability are critical.

Magnetic Sensor Comparison

The AS5600 is one of several magnetic rotary position sensors available in the market. Here’s a comparison of the AS5600 with some other popular magnetic sensors:

| Sensor | Resolution | Interface | Package |

|---|---|---|---|

| AS5600 | 12 bits | I2C | TSSOP-16 |

| AS5048A | 14 bits | SPI | TSSOP-14 |

| TLV493D | 12 bits | I2C | TSOP-6 |

| MA730 | 14 bits | Analog | TSSOP-16 |

While each sensor has its own unique features and advantages, the AS5600 stands out for its high resolution, I2C interface, and compact package, making it a versatile choice for many applications.

FAQ

-

What is the maximum operating voltage of the AS5600?

The AS5600 can operate with a supply voltage range of 3.3V to 5V. -

How does the AS5600 communicate with a microcontroller?

The AS5600 uses the I2C communication protocol to exchange data with a microcontroller. It supports standard (100 kHz) and fast (400 kHz) I2C modes. -

What is the resolution of the AS5600?

The AS5600 offers a 12-bit angular resolution, which translates to 0.088° per step. -

Can the zero position of the AS5600 be programmed?

Yes, the AS5600 allows users to program the zero position by writing the desired value to the sensor’s zero position register. -

What is the typical current consumption of the AS5600?

The AS5600 has a low current consumption, typically less than 10 mA during normal operation.

Conclusion

The AS5600 is a high-performance magnetic rotary position sensor that offers precise, contactless angular measurement with 12-bit resolution. Its Hall effect sensing technology, combined with advanced signal processing, provides accurate and reliable position data for a wide range of applications.

With its low power consumption, compact size, and programmable features, the AS5600 is an attractive choice for designers seeking a versatile and efficient rotary position sensing solution. Whether used in industrial automation, automotive systems, or consumer electronics, the AS5600 delivers exceptional performance and reliability.

By understanding the working principles, benefits, and implementation details of the AS5600, engineers and developers can effectively integrate this sensor into their designs, unlocking new possibilities for precise rotary position control and feedback.

Leave a Reply