Introduction to Multilayer PCB

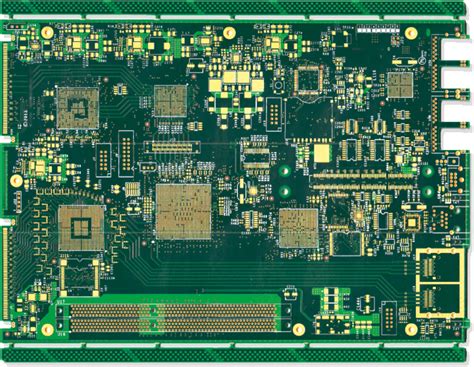

A Multilayer PCB, also known as a multilayer printed circuit board, is a complex and highly advanced type of PCB that consists of multiple layers of conductive material, typically copper, separated by insulating layers. These layers are laminated together to form a single, compact board that can accommodate a high density of components and intricate circuit designs.

Multilayer PCBs have become increasingly popular in recent years, particularly in industries that require high-performance, reliability, and miniaturization, such as telecommunications, aerospace, and medical devices. They offer several advantages over traditional single or double-layer PCBs, including:

- Increased circuit density and complexity

- Improved signal integrity and reduced crosstalk

- Better thermal management and power distribution

- Reduced overall size and weight of the final product

Understanding the Structure of Multilayer PCBs

Basic Layers in a Multilayer PCB

A typical multilayer PCB consists of several key layers, each serving a specific purpose:

-

Copper Layers: These are the conductive layers that form the actual circuit patterns. The number of copper layers can vary depending on the complexity of the design, but most multilayer PCBs have at least four layers (two inner layers and two outer layers).

-

Insulating Layers: Also known as substrate or dielectric layers, these are the non-conductive layers that separate the copper layers and provide electrical insulation. The most common insulating material is FR-4, a glass-reinforced epoxy laminate.

-

Solder Mask: This is a thin, protective layer applied to the outer surfaces of the PCB to prevent accidental short circuits and protect the copper traces from oxidation and damage. It also provides a surface for printing component labels and other markings.

-

Silkscreen: This is a text and symbol layer printed on top of the solder mask to identify components, test points, and other features of the PCB.

Advanced Layers in High-Density Multilayer PCBs

In addition to the basic layers, high-density multilayer PCBs may incorporate additional specialized layers to enhance performance and functionality:

-

Power and Ground Planes: These are solid copper layers that provide low-impedance power distribution and grounding for the circuit. They help to reduce noise, improve signal integrity, and minimize EMI/RFI issues.

-

Signal Layers: These are the layers that contain the actual signal traces for the circuit. They are typically arranged in pairs (e.g., top and bottom layers) to provide a balanced and symmetrical design.

-

Blind and Buried Vias: These are special types of interconnects that connect inner layers without extending to the outer layers of the PCB. Blind vias connect an outer layer to an inner layer, while buried vias connect two or more inner layers without reaching the surface.

Designing Multilayer PCBs

Layer Stackup and Material Selection

The first step in designing a multilayer PCB is to determine the appropriate layer stackup and materials based on the specific requirements of the application. This involves considering factors such as:

- Number of layers required for the circuit complexity

- Desired board thickness and overall dimensions

- Required impedance and signal integrity performance

- Operating environment and temperature range

- Manufacturing capabilities and cost constraints

The choice of materials, particularly the insulating layers, is critical to the performance and reliability of the final product. Factors such as dielectric constant, dissipation factor, and thermal expansion coefficient must be carefully considered to ensure compatibility with the circuit design and manufacturing process.

Signal Integrity and Crosstalk Management

One of the primary challenges in designing multilayer PCBs is ensuring signal integrity and minimizing crosstalk between adjacent traces. This requires careful management of trace geometry, spacing, and impedance, as well as the use of specialized techniques such as:

- Microstrip and stripline routing

- Differential pair routing

- Controlled impedance design

- Ground plane stitching and via shielding

Simulations using electromagnetic field solvers can help to optimize the design and identify potential signal integrity issues before fabrication.

Thermal Management and Power Distribution

Multilayer PCBs often have to dissipate significant amounts of heat generated by high-power components and circuitry. Proper thermal management is essential to ensure reliable operation and prevent component failure. This can be achieved through the use of:

- Thermal vias and heat sinks

- Copper pours and power planes

- Thermal interface materials and heat spreaders

The power distribution network must also be carefully designed to provide stable and low-impedance power delivery to all parts of the circuit. This involves the use of power and ground planes, decoupling capacitors, and proper via placement and sizing.

Manufacturing Multilayer PCBs

Lamination and Pressing

The manufacturing process for multilayer PCBs involves several key steps, starting with the lamination and pressing of the individual layers. The copper foil and prepreg (pre-impregnated) insulating layers are stacked in the proper sequence and aligned using registration holes. The stack is then placed in a heated hydraulic press, where high pressure and temperature are applied to bond the layers together into a solid board.

Drilling and Plating

Once the board has been laminated, the next step is to drill the via holes and plate them with copper to create electrical connections between the layers. This is typically done using computer-controlled drilling machines and electroplating processes. The holes are then filled with a conductive material, such as copper or conductive epoxy, to create a solid interconnect.

Patterning and Etching

The final step in the manufacturing process is to create the actual circuit patterns on the outer and inner layers of the board. This is done using a photolithographic process, where a photoresist coating is applied to the copper layers and exposed to light through a patterned mask. The unexposed areas are then chemically etched away, leaving behind the desired Circuit Traces.

Quality Control and Testing

Throughout the manufacturing process, strict quality control measures are employed to ensure the integrity and reliability of the final product. This includes visual inspections, electrical testing, and destructive testing of sample boards to verify the mechanical and thermal properties of the materials.

Advantages and Applications of Multilayer PCBs

Benefits of Using Multilayer PCBs

Multilayer PCBs offer several key advantages over traditional single or double-layer boards:

-

Increased Circuit Density: By using multiple layers, designers can pack more components and circuitry into a smaller space, enabling more compact and lightweight products.

-

Improved Signal Integrity: The use of dedicated signal layers and proper routing techniques helps to minimize crosstalk and maintain signal integrity, even at high frequencies and data rates.

-

Better Thermal Management: The incorporation of thermal management features such as heat sinks and thermal vias helps to dissipate heat more effectively, improving reliability and performance.

-

Enhanced Mechanical Strength: The laminated construction of multilayer PCBs provides greater mechanical strength and durability compared to single-layer boards.

Applications and Industries

Multilayer PCBs are used in a wide range of applications and industries, including:

- Telecommunications and networking equipment

- Aerospace and defense systems

- Medical devices and instruments

- Automotive electronics and sensors

- Industrial control and automation systems

- Consumer electronics and mobile devices

Frequently Asked Questions (FAQ)

-

What is the typical number of layers in a multilayer PCB?

The number of layers in a multilayer PCB can vary depending on the complexity of the design and the specific requirements of the application. Most multilayer PCBs have at least four layers (two inner layers and two outer layers), but boards with 8, 12, or even 20+ layers are not uncommon in high-density applications. -

What materials are used for the insulating layers in multilayer PCBs?

The most common insulating material used in multilayer PCBs is FR-4, a glass-reinforced epoxy laminate. Other materials such as polyimide, PTFE, and ceramics may be used in high-performance or specialized applications. -

What are blind and buried vias, and why are they used in multilayer PCBs?

Blind and buried vias are special types of interconnects that connect inner layers without extending to the outer layers of the PCB. Blind vias connect an outer layer to an inner layer, while buried vias connect two or more inner layers without reaching the surface. They are used to increase circuit density and minimize the size of the board. -

How are signal integrity and crosstalk managed in multilayer PCB design?

Signal integrity and crosstalk are managed through careful control of trace geometry, spacing, and impedance, as well as the use of specialized routing techniques such as microstrip, stripline, and differential pairs. Ground plane stitching and via shielding may also be employed to minimize noise and interference. -

What are the key steps in the manufacturing process for multilayer PCBs?

The key steps in the manufacturing process for multilayer PCBs include lamination and pressing of the individual layers, drilling and plating of the via holes, and patterning and etching of the circuit traces. Strict quality control measures are employed throughout the process to ensure the integrity and reliability of the final product.

Conclusion

Multilayer PCBs are a critical enabling technology for a wide range of advanced applications and industries. By providing increased circuit density, improved signal integrity, better thermal management, and enhanced mechanical strength, they offer significant advantages over traditional single or double-layer boards.

However, designing and manufacturing multilayer PCBs is a complex and challenging process that requires careful consideration of materials, layer stackup, signal integrity, thermal management, and power distribution. Specialized knowledge and tools, such as electromagnetic field simulators and high-precision manufacturing equipment, are essential for success.

As the demand for high-performance, miniaturized, and reliable electronic products continues to grow, the importance of multilayer PCBs will only continue to increase. By understanding the fundamentals of multilayer PCB design and manufacturing, engineers and designers can unlock new possibilities for innovation and advancement in a wide range of fields.

Leave a Reply