What is a Start-Stop Circuit?

A start-stop circuit is an electrical control system that allows for the safe and efficient operation of machinery or equipment. It consists of a series of components that work together to ensure that the machine starts and stops in a controlled manner, preventing damage to the equipment and ensuring the safety of the operator.

The basic components of a start-stop circuit include:

- A power source (usually AC)

- A start button

- A stop button

- A contactor or relay

- Overload protection (thermal or electronic)

When the start button is pressed, it sends a signal to the contactor or relay, which then closes the circuit and allows power to flow to the motor or other load. When the stop button is pressed, it interrupts the signal to the contactor or relay, causing it to open the circuit and stop the flow of power to the load.

Components of a Start-Stop Circuit

Power Source

The power source for a start-stop circuit is typically an AC supply, either single-phase or three-phase, depending on the requirements of the motor or load. The voltage and frequency of the power supply must match the specifications of the motor or load to ensure proper operation and prevent damage.

Start Button

The start button is a normally open (NO) contact that is used to initiate the start sequence of the circuit. When the button is pressed, it closes the contact and allows current to flow through the circuit, energizing the contactor or relay and starting the motor or load.

Stop Button

The stop button is a normally closed (NC) contact that is used to initiate the stop sequence of the circuit. When the button is pressed, it opens the contact and interrupts the flow of current through the circuit, de-energizing the contactor or relay and stopping the motor or load.

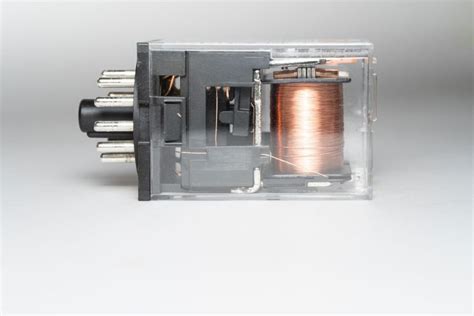

Contactor or Relay

The contactor or relay is an electromechanical switch that is used to control the flow of power to the motor or load. It consists of a coil that, when energized, creates a magnetic field that attracts a set of contacts, closing the circuit and allowing power to flow. When the coil is de-energized, the contacts open, interrupting the flow of power and stopping the motor or load.

Overload Protection

Overload protection is a critical component of a start-stop circuit that is used to protect the motor or load from damage due to excessive current. There are two main types of overload protection:

-

Thermal overload protection: This type of protection uses a bimetallic strip that heats up and bends when exposed to excessive current, opening the circuit and stopping the flow of power to the motor or load.

-

Electronic overload protection: This type of protection uses electronic sensors to monitor the current flowing through the circuit and will trip the circuit if the current exceeds a predetermined threshold.

Working of a Start-Stop Circuit

The basic operation of a start-stop circuit is as follows:

-

When the start button is pressed, it closes the normally open contact and allows current to flow through the circuit, energizing the contactor or relay coil.

-

The energized coil creates a magnetic field that attracts the contacts, closing the circuit and allowing power to flow to the motor or load.

-

The motor or load starts and continues to run as long as the start button is held down or until the stop button is pressed.

-

When the stop button is pressed, it opens the normally closed contact and interrupts the flow of current through the circuit, de-energizing the contactor or relay coil.

-

The de-energized coil releases the contacts, opening the circuit and stopping the flow of power to the motor or load.

-

If the motor or load experiences an overload condition, the overload protection will trip, opening the circuit and stopping the flow of power to prevent damage.

Control of Start-stop Circuits

Start-stop circuits can be controlled in a variety of ways, depending on the specific application and requirements of the system. Some common control methods include:

Manual Control

Manual control is the simplest and most basic form of control for a start-stop circuit. It involves the use of a start button and a stop button that are manually operated by the user. When the start button is pressed, the circuit is energized and the motor or load starts. When the stop button is pressed, the circuit is de-energized and the motor or load stops.

Automatic Control

Automatic control involves the use of sensors, timers, or other devices to automatically start and stop the circuit based on predetermined conditions or events. For example, a temperature sensor could be used to automatically start a cooling fan when the temperature reaches a certain level and stop the fan when the temperature drops below a certain level.

Remote Control

Remote control involves the use of a remote device, such as a wireless transmitter or a smartphone app, to start and stop the circuit from a distance. This type of control is useful in situations where the user needs to control the circuit from a remote location or where it is not practical or safe to manually operate the start and stop buttons.

Programmable Logic Controller (PLC) Control

PLC control involves the use of a programmable logic controller to control the start-stop circuit based on a set of pre-programmed instructions. The PLC can be programmed to monitor various inputs, such as sensors or switches, and control the output of the circuit based on these inputs. This type of control is commonly used in industrial automation applications where complex control schemes are required.

Advantages of Start-Stop Circuits

Start-stop circuits offer several advantages over other types of control systems, including:

Safety

Start-stop circuits provide a safe and reliable way to control the operation of machinery or equipment. The use of a stop button allows the user to quickly and easily stop the machine in the event of an emergency or malfunction, preventing damage to the equipment and ensuring the safety of the operator.

Energy Efficiency

Start-stop circuits can help to reduce energy consumption by allowing the motor or load to be turned off when not in use. This can result in significant energy savings over time, particularly in applications where the motor or load is not required to run continuously.

Reduced Wear and Tear

Start-stop circuits can help to reduce wear and tear on the motor or load by allowing it to be turned off when not in use. This can extend the life of the equipment and reduce maintenance costs over time.

Flexibility

Start-stop circuits can be easily customized to meet the specific requirements of the application. The use of different control methods, such as manual, automatic, remote, or PLC control, allows the circuit to be tailored to the specific needs of the user.

Applications of Start-Stop Circuits

Start-stop circuits are used in a wide range of applications, including:

Industrial Machinery

Start-stop circuits are commonly used to control the operation of industrial machinery, such as conveyors, pumps, and compressors. They provide a safe and reliable way to start and stop the machinery as needed, ensuring efficient operation and reducing the risk of accidents or injuries.

HVAC Systems

Start-stop circuits are used to control the operation of heating, ventilation, and air conditioning (HVAC) systems. They allow the system to be turned on and off as needed, based on factors such as temperature, humidity, and air quality, ensuring optimal performance and energy efficiency.

Lighting Systems

Start-stop circuits are used to control the operation of lighting systems, such as street lights, parking lot lights, and building lights. They allow the lights to be turned on and off as needed, based on factors such as time of day, occupancy, and ambient light levels, reducing energy consumption and maintenance costs.

Irrigation Systems

Start-stop circuits are used to control the operation of irrigation systems, such as sprinklers and drip irrigation systems. They allow the system to be turned on and off as needed, based on factors such as soil moisture levels, weather conditions, and plant requirements, ensuring optimal water usage and plant health.

FAQ

Q1. What is the purpose of a start-stop circuit?

A1. The purpose of a start-stop circuit is to provide a safe and efficient way to control the operation of machinery or equipment. It allows the user to start and stop the machine as needed, preventing damage to the equipment and ensuring the safety of the operator.

Q2. What are the basic components of a start-stop circuit?

A2. The basic components of a start-stop circuit include a power source, a start button, a stop button, a contactor or relay, and overload protection (thermal or electronic).

Q3. What types of overload protection are used in start-stop circuits?

A3. The two main types of overload protection used in start-stop circuits are thermal overload protection, which uses a bimetallic strip that heats up and bends when exposed to excessive current, and electronic overload protection, which uses electronic sensors to monitor the current flowing through the circuit.

Q4. What are some common control methods used for start-stop circuits?

A4. Common control methods used for start-stop circuits include manual control, automatic control, remote control, and programmable logic controller (PLC) control.

Q5. What are some advantages of using start-stop circuits?

A5. Some advantages of using start-stop circuits include improved safety, energy efficiency, reduced wear and tear on equipment, and flexibility in customizing the circuit to meet specific application requirements.

| Component | Function |

|---|---|

| Power Source | Provides the electrical power needed to operate the circuit |

| Start Button | Initiates the start sequence of the circuit |

| Stop Button | Initiates the stop sequence of the circuit |

| Contactor or Relay | Controls the flow of power to the motor or load |

| Overload Protection | Protects the motor or load from damage due to excessive current |

| Control Method | Description |

|---|---|

| Manual Control | Uses a start button and stop button that are manually operated by the user |

| Automatic Control | Uses sensors, timers, or other devices to automatically start and stop the circuit based on predetermined conditions or events |

| Remote Control | Uses a remote device, such as a wireless transmitter or a smartphone app, to start and stop the circuit from a distance |

| PLC Control | Uses a programmable logic controller to control the start-stop circuit based on a set of pre-programmed instructions |

In conclusion, start-stop circuits are a critical component of many industrial and commercial applications, providing a safe and efficient way to control the operation of machinery and equipment. By understanding the basic components, working principles, and control methods of start-stop circuits, users can ensure optimal performance, energy efficiency, and safety in their applications.

Leave a Reply