Introduction to Start-stop Circuits

Start-stop circuits are an essential component in various electrical and electronic systems. They are designed to control the operation of devices by allowing them to be started and stopped as needed. These circuits find applications in a wide range of fields, including industrial automation, motor control, and power management.

In this comprehensive article, we will dive deep into the world of start-stop circuits. We will explore their fundamental concepts, working principles, and practical applications. Whether you are an electrical engineer, a technician, or simply curious about how these circuits work, this article will provide you with a solid understanding of start-stop circuits.

What are Start-Stop Circuits?

Start-stop circuits are electrical circuits that enable the control of a device’s operation by providing a means to start and stop it as required. These circuits typically consist of a power source, a switch or relay, and the controlled device itself.

The primary purpose of a start-stop circuit is to allow the user to initiate or halt the operation of a device based on specific conditions or triggers. This control mechanism is crucial in many applications where precise timing, safety, or energy efficiency is important.

Key Components of Start-Stop Circuits

To understand how start-stop circuits work, let’s take a closer look at their key components:

-

Power Source: The power source provides the necessary electrical energy to the circuit. It can be a battery, a power supply unit, or a connection to the main electrical grid.

-

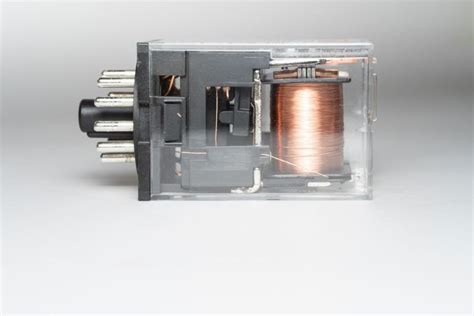

Switch or Relay: The switch or relay acts as the control element in the start-stop circuit. It is responsible for making or breaking the electrical connection between the power source and the controlled device. Switches can be manually operated, while relays are typically controlled by an external signal or voltage.

-

Controlled Device: The controlled device is the component that is being started or stopped by the start-stop circuit. It can be an electric motor, a lighting system, a heating element, or any other electrical device that requires controlled operation.

Types of Start-Stop Circuits

Start-stop circuits can be classified into different types based on their design and functionality. Some common types include:

-

Push Button Start-Stop Circuit: In this type of circuit, the controlled device is started by pressing a momentary push button switch. The device continues to operate until the stop button is pressed or the power is disconnected.

-

Maintained Contact Start-Stop Circuit: This circuit uses a maintained contact switch, such as a toggle switch, to start and stop the controlled device. When the switch is in the “on” position, the device remains operational until the switch is flipped back to the “off” position.

-

Automatic Start-Stop Circuit: Automatic start-stop circuits employ sensors or timers to control the operation of the device based on predefined conditions. For example, a temperature-controlled start-stop circuit can automatically start a cooling fan when the temperature exceeds a certain threshold and stop it when the temperature drops below the desired level.

Working Principle of Start-Stop Circuits

To gain a better understanding of how start-stop circuits function, let’s explore their working principle in more detail.

Basic Operation

In a basic start-stop circuit, the power source is connected to the controlled device through a switch or relay. When the switch is closed or the relay is energized, the electrical current flows from the power source to the controlled device, causing it to start operating. When the switch is opened or the relay is de-energized, the electrical connection is broken, and the controlled device stops.

Latching and Interlocking

In some start-stop circuits, additional features such as latching and interlocking are implemented to enhance safety and prevent unintended operation.

Latching refers to the ability of the circuit to maintain its state even after the initiating signal is removed. For example, in a latching start-stop circuit, once the start button is pressed, the controlled device continues to operate until the stop button is pressed, regardless of whether the start button is released or not.

Interlocking is a safety feature that prevents the simultaneous operation of conflicting devices or actions. In an interlocked start-stop circuit, the start and stop buttons are interconnected in such a way that pressing one button disables the other. This ensures that the controlled device cannot be accidentally started while it is being stopped, or vice versa.

Time Delay and Sequencing

Start-stop circuits can also incorporate time delay and sequencing functionalities to control the timing and order of operations.

Time delay circuits introduce a predetermined time lag between the initiation of the start signal and the actual starting of the controlled device. This delay can be used to allow other processes to complete before the device starts or to provide a grace period for the operator to safely clear the area.

Sequencing circuits control the order in which multiple devices are started or stopped. They ensure that the devices are activated or deactivated in a specific sequence to maintain proper system operation and avoid potential conflicts or damage.

Applications of Start-Stop Circuits

Start-stop circuits find applications in a wide range of industries and settings. Let’s explore some common applications:

Industrial Automation

In industrial automation, start-stop circuits are extensively used to control the operation of machinery, conveyor systems, and production lines. These circuits enable operators to start and stop equipment as needed, ensuring efficient and safe operation.

For example, in a packaging plant, a start-stop circuit can be used to control the operation of a filling machine. The operator can press the start button to initiate the filling process and press the stop button to halt it when the desired quantity is reached.

Motor Control

Start-stop circuits are commonly used in motor control applications. They allow the operator to start and stop electric motors as required, providing precise control over the motor’s operation.

In a pumping system, for instance, a start-stop circuit can be used to control the operation of the pump motor. The circuit can be designed to start the pump when the water level in a tank falls below a certain level and stop it when the tank is full, ensuring efficient water management.

Lighting Control

Start-stop circuits are also employed in lighting control systems. They enable the user to turn lights on and off as needed, providing energy efficiency and convenience.

In a commercial building, a start-stop circuit can be used to control the lighting in common areas such as hallways and lobbies. The circuit can be programmed to turn the lights on during business hours and turn them off during off-hours, saving energy and reducing operational costs.

HVAC Systems

Start-stop circuits play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They control the operation of compressors, fans, and other components to maintain a comfortable and efficient indoor environment.

In a residential HVAC system, a start-stop circuit can be used to control the operation of the air conditioning unit. The circuit can be triggered by a thermostat to start the compressor when the room temperature rises above the set point and stop it when the desired temperature is reached.

Designing Start-Stop Circuits

Designing effective start-stop circuits requires careful consideration of various factors such as the electrical characteristics of the controlled device, the desired control functionality, and safety requirements. Here are some key considerations when designing start-stop circuits:

Electrical Ratings

It is crucial to select components with appropriate electrical ratings to ensure the safe and reliable operation of the start-stop circuit. The switch or relay should be rated to handle the voltage and current requirements of the controlled device.

Control Logic

The control logic of the start-stop circuit determines how the controlled device is started and stopped based on the input signals and conditions. It is important to design the control logic to meet the specific requirements of the application, such as interlocking, time delay, or sequencing.

Safety Considerations

Safety is a paramount concern when designing start-stop circuits. The circuit should incorporate appropriate safety features such as emergency stop buttons, overload protection, and fault detection to prevent accidents and equipment damage.

Wiring and Connections

Proper wiring and connections are essential for the reliable operation of start-stop circuits. The wiring should be properly sized and insulated to handle the expected current and voltage levels. Secure and reliable connections should be made using appropriate terminals, connectors, or soldering techniques.

Troubleshooting Start-Stop Circuits

Despite careful design and installation, start-stop circuits may sometimes encounter problems. Effective troubleshooting skills are essential to identify and resolve issues promptly. Here are some common troubleshooting steps:

Visual Inspection

Start by visually inspecting the start-stop circuit for any obvious signs of damage, loose connections, or burnt components. Check for frayed wires, damaged insulation, or signs of overheating.

Continuity Testing

Use a multimeter to perform continuity tests on the wiring and components of the start-stop circuit. This helps to identify any open or short circuits that may be preventing proper operation.

Voltage Measurements

Measure the voltage levels at various points in the start-stop circuit to ensure that the proper voltage is being supplied to the controlled device. Check for voltage drops or fluctuations that may indicate a problem with the power source or wiring.

Component Testing

Test individual components of the start-stop circuit, such as switches, relays, and sensors, to verify their proper functioning. Replace any faulty components with compatible replacements.

Logical Troubleshooting

Follow the control logic of the start-stop circuit to identify where the problem may be occurring. Systematically test each step of the control sequence to pinpoint the source of the issue.

Frequently Asked Questions (FAQ)

-

What is the difference between a maintained and momentary start-stop circuit?

In a maintained start-stop circuit, the controlled device continues to operate as long as the start switch is in the “on” position. In a momentary start-stop circuit, the controlled device operates only while the start button is being pressed and stops when the button is released. -

Can a start-stop circuit be used with AC and DC power sources?

Yes, start-stop circuits can be designed to work with both AC and DC power sources. However, the specific components and design considerations may vary depending on the type of power source being used. -

What is the purpose of interlocking in a start-stop circuit?

Interlocking is a safety feature in start-stop circuits that prevents the simultaneous operation of conflicting devices or actions. It ensures that the controlled device cannot be accidentally started while it is being stopped, or vice versa, reducing the risk of accidents or equipment damage. -

How can I add a time delay to a start-stop circuit?

To add a time delay to a start-stop circuit, you can incorporate a time delay relay or a Timer Circuit. These components introduce a predetermined time lag between the initiation of the start signal and the actual starting of the controlled device, allowing for necessary processes to complete or providing a grace period for safety. -

What should I do if my start-stop circuit is not working properly?

If your start-stop circuit is not functioning as intended, you should follow a systematic troubleshooting approach. Start by visually inspecting the circuit for any obvious signs of damage or loose connections. Perform continuity tests and voltage measurements to identify potential issues. Test individual components and follow the control logic to pinpoint the source of the problem. If the issue persists, consult the manufacturer’s documentation or seek assistance from a qualified technician.

Conclusion

Start-stop circuits are fundamental components in various electrical and electronic systems, providing a means to control the operation of devices as needed. Understanding their working principles, applications, and design considerations is essential for effective implementation and troubleshooting.

In this comprehensive article, we have explored the key aspects of start-stop circuits, including their components, types, working principles, and practical applications. We have also discussed the design considerations and troubleshooting techniques to ensure the reliable and safe operation of these circuits.

By mastering the concepts and principles of start-stop circuits, electrical engineers, technicians, and enthusiasts can design, install, and maintain efficient and robust control systems across a wide range of industries and applications.

Remember, safety should always be the top priority when working with electrical circuits. Follow proper safety guidelines, use appropriate personal protective equipment, and consult professional assistance when necessary.

With a solid understanding of start-stop circuits, you can contribute to the development of innovative and reliable control systems that drive the modern world.

Leave a Reply