Introduction to CAD2CAM4PCB

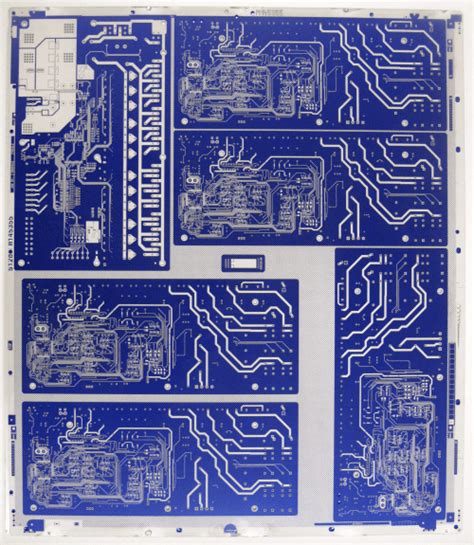

CAD2CAM4PCB is an innovative software solution that streamlines the PCB design and manufacturing process by seamlessly integrating computer-aided design (CAD) with computer-aided manufacturing (CAM). This powerful tool enables engineers and designers to efficiently create high-quality printed circuit boards (PCBs) while minimizing errors and reducing overall production time.

The recent CAD2CAM4PCB seminar, held at the state-of-the-art technology center, attracted a diverse group of attendees, including PCB designers, engineers, and industry professionals. The event provided an excellent opportunity for participants to learn about the latest advancements in PCB design and manufacturing technology, as well as network with their peers.

Key Features of CAD2CAM4PCB

CAD2CAM4PCB offers a wide range of features that make it an indispensable tool for PCB design and manufacturing. Some of the key features include:

- Seamless integration between CAD and CAM

- Intelligent design rule checks (DRC)

- Automated component placement and routing

- 3D visualization and simulation

- Comprehensive library management

- Flexible output options for various manufacturing processes

Seamless Integration Between CAD and CAM

One of the most significant advantages of CAD2CAM4PCB is its ability to bridge the gap between CAD and CAM. By integrating these two essential aspects of PCB design and manufacturing, the software enables users to create designs that are optimized for manufacturability from the outset. This integration helps to minimize errors, reduce iterations, and ultimately, save time and money.

Intelligent Design Rule Checks (DRC)

CAD2CAM4PCB features intelligent design rule checks that help to ensure the integrity and reliability of PCB designs. These checks automatically detect and flag potential issues, such as signal integrity problems, electromagnetic interference (EMI), and thermal management concerns. By identifying these issues early in the design process, engineers can make the necessary adjustments to prevent costly rework and delays down the line.

Automated Component Placement and Routing

The software’s advanced algorithms for component placement and routing significantly reduce the time and effort required to create complex PCB layouts. CAD2CAM4PCB can automatically place components based on user-defined constraints and optimize routing to minimize signal interference and maximize board space utilization. This automation allows designers to focus on higher-level aspects of the design, such as functionality and performance.

3D Visualization and Simulation

CAD2CAM4PCB offers powerful 3D visualization and simulation capabilities that enable users to view their designs from every angle and test their performance under various conditions. This feature is particularly useful for identifying potential issues related to component clearance, thermal management, and mechanical stress. By simulating the behavior of the PCB in a virtual environment, designers can make informed decisions and optimize their designs for real-world applications.

Comprehensive Library Management

The software includes a comprehensive library management system that allows users to organize and access a wide range of components, footprints, and symbols. This feature enables designers to quickly locate and incorporate the necessary elements into their designs, saving time and ensuring consistency across projects. Additionally, CAD2CAM4PCB supports the import and export of popular library formats, making it easy to collaborate with external partners and suppliers.

Flexible Output Options for Various Manufacturing Processes

CAD2CAM4PCB supports a variety of output options to cater to different manufacturing processes and requirements. Users can generate industry-standard output files, such as Gerber, ODB++, and IPC-2581, which are compatible with most PCB fabrication and assembly equipment. This flexibility ensures that designs can be seamlessly transferred to manufacturing partners, reducing the risk of errors and delays.

Benefits of Using CAD2CAM4PCB

Implementing CAD2CAM4PCB in the PCB design and manufacturing process offers numerous benefits, including:

- Improved design efficiency and accuracy

- Reduced time-to-market

- Enhanced collaboration between design and manufacturing teams

- Lower production costs

- Increased product quality and reliability

| Benefit | Description |

|---|---|

| Improved design efficiency and accuracy | CAD2CAM4PCB’s intelligent features and automation capabilities help to streamline the design process, reducing the time and effort required to create high-quality PCB layouts. The software’s design rule checks and simulation tools also help to minimize errors and ensure the accuracy of the final product. |

| Reduced time-to-market | By integrating CAD and CAM, CAD2CAM4PCB enables designers to create manufacturing-ready designs from the outset. This approach minimizes the need for iterations and rework, ultimately reducing the overall time required to bring a product to market. |

| Enhanced collaboration between design and manufacturing teams | CAD2CAM4PCB’s comprehensive library management and flexible output options facilitate seamless collaboration between design and manufacturing teams. This collaboration helps to ensure that designs are optimized for manufacturability and that any potential issues are identified and addressed early in the process. |

| Lower production costs | The software’s automation features and optimization capabilities help to minimize material waste, reduce the need for manual intervention, and increase overall production efficiency. These improvements translate into lower production costs and higher profit margins. |

| Increased product quality and reliability | CAD2CAM4PCB’s advanced simulation and analysis tools enable designers to test and refine their designs in a virtual environment, ensuring that the final product meets the highest standards of quality and reliability. This approach helps to minimize the risk of field failures and warranty claims, protecting the company’s reputation and bottom line. |

Real-World Applications of CAD2CAM4PCB

CAD2CAM4PCB has been successfully implemented in a wide range of industries, including:

- Consumer electronics

- Automotive

- Aerospace and defense

- Medical devices

- Industrial automation

Consumer Electronics

In the fast-paced world of consumer electronics, CAD2CAM4PCB has proven to be an invaluable tool for companies looking to stay ahead of the competition. By enabling designers to create complex, high-density PCB layouts quickly and accurately, the software helps to reduce development cycles and bring new products to market faster. Additionally, CAD2CAM4PCB’s simulation capabilities allow designers to test and optimize their designs for factors such as signal integrity and thermal management, ensuring that the final product meets the demanding performance and reliability requirements of the consumer electronics industry.

Automotive

The automotive industry relies heavily on advanced electronics to power the latest safety, entertainment, and navigation systems. CAD2CAM4PCB plays a critical role in the development of these systems, enabling designers to create robust, reliable PCB layouts that can withstand the harsh environmental conditions encountered in automotive applications. The software’s automated design rule checks and 3D visualization features help to ensure that designs meet the stringent quality and safety standards required by the industry.

Aerospace and Defense

In the aerospace and defense sector, PCBs must be designed to operate reliably in extreme conditions, including high altitudes, extreme temperatures, and exposure to radiation. CAD2CAM4PCB’s advanced simulation and analysis tools enable designers to test and optimize their designs for these challenging environments, ensuring that the final product meets the rigorous performance and reliability requirements of the industry. The software’s comprehensive library management and collaboration features also make it easier for teams to work together on complex, multi-disciplinary projects.

Medical Devices

Medical devices require the highest levels of quality, reliability, and safety, as they are often used in life-critical applications. CAD2CAM4PCB helps medical device manufacturers to meet these demanding requirements by providing a powerful, integrated platform for PCB design and manufacturing. The software’s intelligent design rule checks and simulation capabilities help to ensure that designs are optimized for manufacturability and performance, while its flexible output options make it easy to collaborate with external partners and suppliers.

Industrial Automation

In the world of industrial automation, PCBs play a crucial role in controlling and monitoring complex machinery and processes. CAD2CAM4PCB enables designers to create robust, reliable PCB layouts that can withstand the harsh conditions encountered in industrial environments, such as vibration, dust, and extreme temperatures. The software’s advanced features, such as automated component placement and routing, help to streamline the design process and ensure that designs are optimized for manufacturability and performance.

CAD2CAM4PCB Seminar Highlights

The recent CAD2CAM4PCB seminar provided attendees with a wealth of information and insights into the latest advancements in PCB design and manufacturing technology. Some of the key highlights of the event included:

- In-depth product demonstrations

- Expert-led training sessions

- Real-world case studies

- Networking opportunities

In-Depth Product Demonstrations

Throughout the seminar, attendees had the opportunity to see CAD2CAM4PCB in action through a series of in-depth product demonstrations. These demonstrations showcased the software’s powerful features and capabilities, including its seamless integration between CAD and CAM, intelligent design rule checks, and advanced simulation tools. Attendees were able to ask questions and get hands-on experience with the software, gaining a deeper understanding of how it can be used to streamline their PCB design and manufacturing processes.

Expert-Led Training Sessions

In addition to product demonstrations, the seminar featured a series of expert-led training sessions designed to help attendees get the most out of CAD2CAM4PCB. These sessions covered a wide range of topics, from basic software navigation and setup to advanced design techniques and best practices. Attendees had the opportunity to learn from experienced professionals and gain the skills and knowledge needed to effectively use CAD2CAM4PCB in their own organizations.

Real-World Case Studies

One of the highlights of the seminar was the presentation of real-world case studies showcasing the successful implementation of CAD2CAM4PCB in various industries. These case studies provided valuable insights into how the software has been used to overcome complex design challenges, improve efficiency, and reduce costs. Attendees were able to learn from the experiences of their peers and gain a better understanding of the tangible benefits that CAD2CAM4PCB can provide.

Networking Opportunities

In addition to the formal presentations and training sessions, the CAD2CAM4PCB seminar provided attendees with ample opportunities to network with their peers and industry experts. These networking sessions allowed attendees to share their experiences, discuss common challenges, and learn from one another in a collaborative and supportive environment. Many attendees left the seminar with new contacts and valuable insights that will help them to further their careers and drive success in their organizations.

FAQ

-

What is CAD2CAM4PCB?

CAD2CAM4PCB is an innovative software solution that integrates computer-aided design (CAD) with computer-aided manufacturing (CAM) to streamline the PCB design and manufacturing process. It offers a wide range of features, including intelligent design rule checks, automated component placement and routing, 3D visualization and simulation, and comprehensive library management. -

What are the benefits of using CAD2CAM4PCB?

Using CAD2CAM4PCB offers numerous benefits, including improved design efficiency and accuracy, reduced time-to-market, enhanced collaboration between design and manufacturing teams, lower production costs, and increased product quality and reliability. The software’s advanced features and automation capabilities help to streamline the design process, minimize errors, and ensure that designs are optimized for manufacturability. -

In which industries is CAD2CAM4PCB commonly used?

CAD2CAM4PCB is used in a wide range of industries, including consumer electronics, automotive, aerospace and defense, medical devices, and industrial automation. The software’s powerful features and flexibility make it well-suited for applications that require high levels of quality, reliability, and performance. -

What types of output files does CAD2CAM4PCB support?

CAD2CAM4PCB supports a variety of industry-standard output files, such as Gerber, ODB++, and IPC-2581. These file formats are compatible with most PCB fabrication and assembly equipment, ensuring that designs can be seamlessly transferred to manufacturing partners. -

How can I learn more about CAD2CAM4PCB and its capabilities?

To learn more about CAD2CAM4PCB and its capabilities, you can attend a seminar or training session, visit the official website, or contact a sales representative for more information. Additionally, many online resources, such as tutorials, user forums, and case studies, can provide valuable insights into how the software can be used to improve PCB design and manufacturing processes.

Conclusion

The recent CAD2CAM4PCB seminar was a resounding success, providing attendees with valuable insights, hands-on experience, and networking opportunities. The event showcased the powerful capabilities of CAD2CAM4PCB and demonstrated how the software can be used to streamline PCB design and manufacturing processes, reduce costs, and improve product quality and reliability.

As the demands on PCB designers and manufacturers continue to grow, tools like CAD2CAM4PCB will become increasingly essential for staying competitive in today’s fast-paced, innovation-driven market. By adopting this powerful software solution, companies can position themselves for success and ensure that they are able to meet the evolving needs of their customers and stakeholders.

Whether you are a seasoned PCB designer or a newcomer to the field, investing in CAD2CAM4PCB is a smart choice that can pay dividends for years to come. With its advanced features, comprehensive support, and proven track record of success, CAD2CAM4PCB is the ultimate tool for anyone looking to take their PCB design and manufacturing capabilities to the next level.

Leave a Reply