What is IATF Certification?

IATF (International Automotive Task Force) certification is a globally recognized quality management system standard specifically designed for the automotive industry. It is based on the ISO 9001 standard but includes additional requirements that are specific to the automotive sector. The IATF 16949 standard, which is the current version, was developed by the IATF in collaboration with major automotive manufacturers and suppliers to ensure the highest quality standards throughout the automotive supply chain.

Benefits of IATF Certification

Obtaining IATF certification offers numerous benefits for companies in the automotive industry, including:

- Improved quality management systems

- Enhanced customer satisfaction

- Increased efficiency and productivity

- Reduced costs associated with defects and rework

- Better risk management and continual improvement

- Improved market competitiveness and global recognition

RAYPCB’s Journey to IATF Certification

RAYPCB, a leading PCB manufacturer, has successfully achieved IATF 16949 certification, demonstrating its commitment to delivering high-quality products and services to its automotive customers. The company’s journey to IATF certification involved several key steps:

1. Gap Analysis and Planning

The first step in RAYPCB’s IATF certification journey was conducting a thorough gap analysis to identify areas where the company’s existing quality management system needed improvement to meet the IATF 16949 requirements. This analysis helped the company develop a comprehensive plan to address any gaps and ensure compliance with the standard.

2. Training and Awareness

To ensure a successful implementation of the IATF 16949 standard, RAYPCB invested in extensive training and awareness programs for its employees. This included:

- Training sessions on the IATF 16949 requirements and their importance

- Workshops on specific topics such as risk management, continual improvement, and customer focus

- Regular communication and updates on the progress of the certification process

3. Process Improvement and Documentation

RAYPCB conducted a thorough review of its existing processes and procedures to identify areas for improvement and ensure alignment with the IATF 16949 requirements. This involved:

- Updating and creating new documentation, such as quality manuals, work instructions, and records

- Implementing new processes and tools to enhance quality control and risk management

- Establishing key performance indicators (KPIs) to monitor and measure the effectiveness of the quality management system

4. Internal Audits and Management Review

To ensure the effectiveness of its quality management system and prepare for the IATF certification audit, RAYPCB conducted regular internal audits and management reviews. These activities helped the company:

- Identify and address any non-conformities or areas for improvement

- Evaluate the performance of the quality management system against the IATF 16949 requirements

- Make necessary adjustments and improvements based on the audit findings and management input

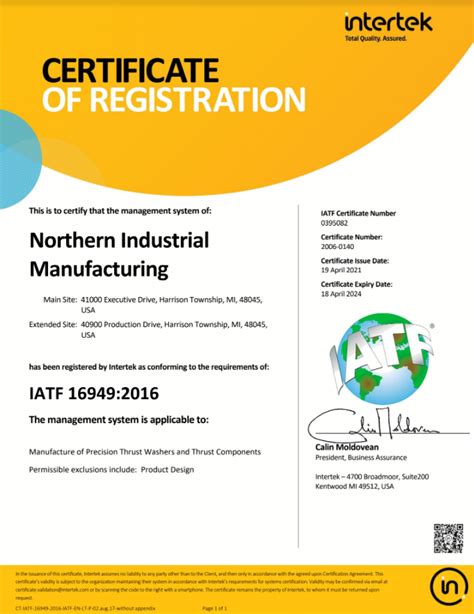

5. IATF Certification Audit

After completing the necessary preparations, RAYPCB underwent the IATF certification audit, which was conducted by an accredited third-party certification body. The audit process included:

- A thorough review of the company’s quality management system documentation

- On-site assessments of the company’s processes, facilities, and operations

- Interviews with employees at various levels of the organization

Upon successful completion of the audit, RAYPCB was awarded the IATF 16949 certificate, recognizing its compliance with the standard and its commitment to quality excellence in the automotive industry.

The Impact of IATF Certification on RAYPCB’s Operations

Achieving IATF certification has had a significant impact on RAYPCB’s operations, leading to numerous improvements and benefits, such as:

1. Enhanced Quality Control

With the implementation of the IATF 16949 standard, RAYPCB has strengthened its quality control processes, leading to:

- Reduced defects and non-conformities

- Improved product consistency and reliability

- Faster detection and resolution of quality issues

2. Increased Customer Satisfaction

By consistently delivering high-quality PCBs that meet or exceed customer requirements, RAYPCB has experienced:

- Higher customer satisfaction rates

- Increased customer loyalty and repeat business

- Positive feedback and testimonials from automotive customers

3. Improved Efficiency and Productivity

The streamlined processes and continual improvement approach fostered by the IATF 16949 standard have enabled RAYPCB to:

- Optimize its production processes and reduce waste

- Improve communication and collaboration among departments

- Achieve higher productivity levels and shorter lead times

4. Reduced Costs and Risks

By focusing on defect prevention and risk management, RAYPCB has been able to:

- Minimize the costs associated with rework, scrap, and warranty claims

- Identify and mitigate potential risks before they impact the business

- Allocate resources more effectively to support quality objectives

5. Competitive Advantage and Growth Opportunities

Having achieved IATF certification, RAYPCB has gained a significant competitive advantage in the automotive PCB Market, leading to:

- Increased market share and new business opportunities

- Improved reputation and brand recognition in the automotive industry

- Stronger relationships with existing and potential automotive customers

RAYPCB’s Commitment to Continual Improvement

One of the key principles of the IATF 16949 standard is continual improvement, and RAYPCB has embraced this philosophy wholeheartedly. The company has established a robust continual improvement framework that includes:

1. Regular Management Reviews

RAYPCB’s top management conducts regular reviews of the quality management system to:

- Assess its effectiveness and identify areas for improvement

- Set quality objectives and targets

- Allocate resources and support for continual improvement initiatives

2. Employee Engagement and Empowerment

RAYPCB actively involves its employees in the continual improvement process by:

- Encouraging them to suggest ideas and improvements

- Providing training and resources to support their participation

- Recognizing and rewarding their contributions to quality excellence

3. Ongoing Monitoring and Measurement

To ensure the effectiveness of its continual improvement efforts, RAYPCB:

- Monitors key performance indicators (KPIs) related to quality, efficiency, and customer satisfaction

- Conducts regular internal audits and assessments

- Analyzes data and trends to identify improvement opportunities

4. Benchmarking and Best Practices

RAYPCB stays up-to-date with industry best practices and trends by:

- Participating in automotive industry events and conferences

- Collaborating with customers, suppliers, and industry partners

- Benchmarking its performance against industry leaders and standards

FAQ

-

What is the difference between IATF 16949 and ISO 9001?

IATF 16949 is based on the ISO 9001 standard but includes additional requirements specific to the automotive industry. While ISO 9001 is a general quality management system standard applicable to various industries, IATF 16949 focuses on the unique needs and expectations of automotive customers. -

How long does it take to achieve IATF certification?

The time required to achieve IATF certification varies depending on factors such as the size and complexity of the organization, the current state of its quality management system, and the resources allocated to the certification process. On average, it can take 6 to 12 months to prepare for and successfully complete the IATF certification audit. -

Is IATF certification mandatory for automotive suppliers?

While IATF certification is not legally mandatory, it is often required by major automotive manufacturers as a condition of doing business. Many automotive OEMs (Original Equipment Manufacturers) and Tier 1 suppliers prefer to work with IATF-certified suppliers to ensure the highest quality standards and minimize supply chain risks. -

How often do companies need to renew their IATF certification?

IATF certification is valid for three years from the date of the initial certification audit. To maintain the certification, companies must undergo annual surveillance audits in the first and second years, followed by a recertification audit in the third year. This cycle ensures that companies continue to meet the IATF 16949 requirements and demonstrate ongoing commitment to quality excellence. -

What are the consequences of losing IATF certification?

Losing IATF certification can have serious consequences for a company in the automotive industry. It may lead to the loss of existing customers, difficulty in attracting new business, and damage to the company’s reputation. In some cases, automotive OEMs may even terminate contracts with suppliers that fail to maintain their IATF certification. Therefore, it is crucial for companies to consistently adhere to the IATF 16949 requirements and address any non-conformities promptly to avoid losing their certification.

Conclusion

RAYPCB’s successful achievement of IATF certification is a testament to the company’s unwavering commitment to quality excellence and customer satisfaction in the automotive industry. By embracing the principles and requirements of the IATF 16949 standard, RAYPCB has not only enhanced its quality management system but also unlocked numerous benefits, including improved efficiency, reduced costs, and increased competitiveness.

As RAYPCB continues its journey of continual improvement, the company remains dedicated to providing its automotive customers with the highest-quality PCBs and services. With its IATF certification and strong focus on quality, RAYPCB is well-positioned to meet the evolving needs of the automotive industry and strengthen its position as a trusted partner for Automotive PCB solutions.

| Benefit | Description |

|---|---|

| Improved quality management systems | IATF certification helps companies establish robust quality management systems that ensure consistent product quality and meet customer requirements. |

| Enhanced customer satisfaction | By consistently delivering high-quality products and services, IATF-certified companies can improve customer satisfaction and loyalty. |

| Increased efficiency and productivity | The streamlined processes and continual improvement approach fostered by the IATF 16949 standard lead to higher efficiency and productivity levels. |

| Reduced costs and risks | IATF certification focuses on defect prevention and risk management, helping companies minimize costs associated with quality issues and mitigate potential risks. |

| Competitive advantage and growth opportunities | Achieving IATF certification gives companies a competitive edge in the automotive industry, leading to increased market share and new business opportunities. |

In conclusion, RAYPCB’s IATF certification is a significant milestone that demonstrates the company’s dedication to delivering the highest-quality PCBs and services to its automotive customers. By embracing the principles of continual improvement and maintaining its commitment to the IATF 16949 standard, RAYPCB is well-equipped to navigate the challenges and opportunities of the automotive industry and continue its success story as a leading PCB manufacturer.

Leave a Reply