Introduction to RAYPCB+Stackup”>RAYPCB Stackup

RAYPCB, a leading manufacturer of printed circuit boards (PCBs), has recently updated its standard stackup for multi-layer PCBs. This update aims to provide customers with enhanced reliability, improved signal integrity, and better overall performance for their PCB Designs.

What is a PCB Stackup?

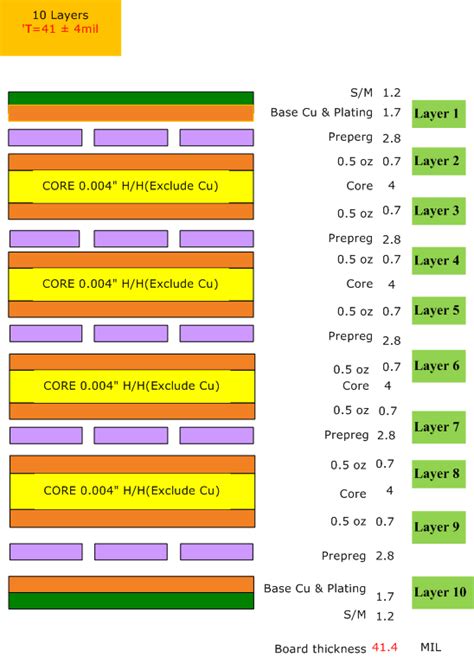

A PCB stackup refers to the arrangement of copper layers and insulating materials that make up a multi-layer PCB. The stackup defines the number of layers, their order, and the thickness of each layer. It also specifies the type of material used for the insulating layers, such as FR-4, Rogers, or Isola.

Why is a PCB Stackup Important?

The PCB stackup plays a crucial role in determining the performance and reliability of a multi-layer PCB. It affects several key aspects, including:

- Signal integrity: The stackup influences the impedance, crosstalk, and signal attenuation of the PCB.

- Power distribution: The arrangement of power and ground layers in the stackup affects the PCB’s ability to provide stable power to components.

- Thermal management: The stackup can impact the PCB’s ability to dissipate heat generated by components.

- Manufacturing feasibility: The stackup must be designed in a way that is feasible for manufacturing and assembly.

RAYPCB’s Updated Standard Stackup

RAYPCB has updated its standard stackup for multi-layer PCBs to address the evolving needs of its customers. The updated stackup offers several improvements over the previous version:

Increased Number of Layers

The updated stackup now supports up to 16 layers, compared to the previous limit of 12 layers. This increase allows for more complex designs and higher component densities.

| Number of Layers | Previous Stackup | Updated Stackup |

|---|---|---|

| 4 | Supported | Supported |

| 6 | Supported | Supported |

| 8 | Supported | Supported |

| 10 | Supported | Supported |

| 12 | Supported | Supported |

| 14 | Not Supported | Supported |

| 16 | Not Supported | Supported |

Improved Impedance Control

RAYPCB has optimized the dielectric thickness and copper weight of each layer to improve impedance control. This enhancement ensures better signal integrity and reduces signal distortion.

| Layer Type | Previous Dielectric Thickness | Updated Dielectric Thickness |

|---|---|---|

| Signal Layer | 0.2mm | 0.15mm |

| Power Layer | 0.3mm | 0.2mm |

| Ground Layer | 0.3mm | 0.2mm |

Enhanced Power Distribution

The updated stackup features dedicated power and ground layers for improved power distribution. These layers are strategically placed to minimize impedance and reduce voltage drop.

| Layer Type | Previous Stackup | Updated Stackup |

|---|---|---|

| Power Layer | 1 | 2 |

| Ground Layer | 1 | 2 |

Expanded Material Options

RAYPCB now offers a wider range of insulating materials to choose from, catering to different application requirements. In addition to the standard FR-4, customers can select from high-performance materials such as Rogers and Isola.

| Material | Previous Stackup | Updated Stackup |

|---|---|---|

| FR-4 | Supported | Supported |

| Rogers | Not Supported | Supported |

| Isola | Not Supported | Supported |

Benefits of RAYPCB’s Updated Stackup

The updated standard stackup brings several benefits to RAYPCB’s customers:

Improved Signal Integrity

With optimized dielectric thickness and copper weight, the updated stackup ensures better signal integrity. This improvement minimizes signal distortion, crosstalk, and attenuation, resulting in more reliable PCB Performance.

Enhanced Power Distribution

The dedicated power and ground layers in the updated stackup provide stable power distribution to components. This enhancement reduces voltage drop and improves overall power integrity, leading to better PCB performance and reliability.

Increased Design Flexibility

The increased number of layers and expanded material options in the updated stackup offer greater design flexibility. Customers can now design more complex PCBs with higher component densities, catering to a wider range of applications.

Better Thermal Management

The updated stackup’s optimized layer arrangement and material selection contribute to better thermal management. This improvement helps dissipate heat generated by components more effectively, ensuring the PCB operates within acceptable temperature ranges.

RAYPCB’s Commitment to Quality

RAYPCB is committed to providing its customers with high-quality PCBs that meet their specific requirements. The updated standard stackup is a testament to this commitment, as it demonstrates RAYPCB’s continuous efforts to improve its products and services.

Rigorous Testing and Quality Control

All PCBs manufactured by RAYPCB undergo rigorous testing and quality control procedures to ensure they meet the highest standards. These procedures include:

- Visual inspection

- Electrical testing

- Impedance testing

- Thermal stress testing

- Microsectioning

Certifications and Standards

RAYPCB holds several industry certifications and adheres to international standards, ensuring the quality and reliability of its PCBs. These certifications and standards include:

- ISO 9001

- UL

- IPC Class 2 and 3

- RoHS

- REACH

Customer Support and Service

RAYPCB prides itself on providing excellent customer support and service. The company’s experienced team of engineers and support staff are always ready to assist customers with their PCB design and manufacturing needs.

FAQ

1. What is the maximum number of layers supported by RAYPCB’s updated standard stackup?

RAYPCB’s updated standard stackup supports up to 16 layers for multi-layer PCBs.

2. What materials are available for the insulating layers in RAYPCB’s updated stackup?

RAYPCB offers a range of insulating materials, including FR-4, Rogers, and Isola, to cater to different application requirements.

3. How does the updated stackup improve signal integrity?

The updated stackup features optimized dielectric thickness and copper weight, which minimize signal distortion, crosstalk, and attenuation, resulting in better signal integrity.

4. Does the updated stackup offer better thermal management?

Yes, the updated stackup’s optimized layer arrangement and material selection contribute to better thermal management, helping to dissipate heat generated by components more effectively.

5. What quality control measures does RAYPCB employ to ensure the reliability of its PCBs?

RAYPCB employs rigorous testing and quality control procedures, including visual inspection, electrical testing, impedance testing, thermal stress testing, and microsectioning, to ensure the highest standards of quality and reliability.

Conclusion

RAYPCB’s updated standard stackup for multi-layer PCBs demonstrates the company’s commitment to providing its customers with high-quality, reliable, and performance-optimized PCBs. With an increased number of layers, improved impedance control, enhanced power distribution, and expanded material options, the updated stackup offers numerous benefits to customers.

As a trusted manufacturer of PCBs, RAYPCB continuously strives to improve its products and services to meet the evolving needs of its customers. The updated standard stackup is just one example of how RAYPCB stays at the forefront of the PCB industry, delivering innovative solutions that enable its customers to create cutting-edge electronic products.

Leave a Reply