What is a PCB?

A printed circuit board, or PCB, is a board made of insulating material like fiberglass with conductive copper traces printed onto it in a specific pattern. The copper traces on the PCB serve as wires to electrically connect the various components that are soldered onto the board.

PCBs are designed using special software for a specific circuit and then manufactured, usually in a factory. The pattern of copper traces connects the components in the proper configuration to make the circuit functional.

Advantages of PCBs

PCBs offer several advantages for electronic circuits:

- Compact and durable – Components mount directly on the board, allowing for smaller and more resilient packaging of the circuit

- Reliable connections – Soldered connections are permanent and less prone to loosening or breaking than other methods

- Reproducible – PCBs are manufactured based on the circuit design, so they can be consistently mass-produced

- Supports Surface Mount Devices – Smaller surface mount components can be used on a PCB to make the circuit even more compact

Disadvantages of PCBs

There are some potential downsides to using PCBs as well:

- Higher cost and effort to produce – Designing a PCB and having it manufactured takes more time, specialized skills, and expense compared to simpler options

- Difficult to modify – Once a PCB is fabricated, it cannot be easily changed, so the circuit design must be finalized before manufacturing

- Requires soldering – Components must be soldered to the PCB, which requires tools and skills that may pose a barrier for beginners

What is a Breadboard?

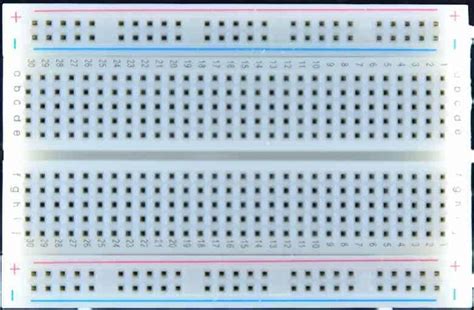

A breadboard is a rectangular plastic board with a grid of holes that can accept wire leads and component legs. Underneath the holes are metal strips that serve to connect holes in the shorter rows. Typically the metal strips run horizontally across the breadboard.

To build a circuit on a breadboard, the legs of components like resistors, capacitors, and Integrated Circuits are inserted into the holes. Wires can be used to make connections between components by inserting their ends into the appropriate holes. In this way, the components are interconnected to form a functional circuit.

Advantages of Breadboards

Breadboards provide several benefits, especially for prototyping:

- No soldering required – Components and wires are simply inserted into the breadboard holes, so no soldering tools or skills are needed

- Reusable – The components can be easily removed and the breadboard reused for other circuits

- Easy to modify – It’s simple to change connections or swap components while experimenting with a circuit design

- Low cost – Breadboards themselves are inexpensive and the components can be reused, making it an economical choice

Disadvantages of Breadboards

Breadboards have some limitations compared to other construction methods:

- Less durable – The connections are not as robust as with soldering, so breadboard circuits are better suited for temporary prototypes than long-term use

- Larger circuits can get messy – With many wires and components, a breadboard can become cluttered and confusing

- Not as compact – The breadboard itself and the components take up more space than with a PCB

- Not suitable for high frequency circuits – The capacitance and inductance of the metal strips can distort signals at high frequencies

PCB vs Breadboard Comparison

While PCBs and breadboards both have their place in electronics projects, they differ in some key aspects. This table summarizes the main differences between PCB and breadboard:

| Feature | PCB | Breadboard |

|---|---|---|

| Construction | Copper traces on insulating board | Plastic board with metal strips beneath holes |

| Component Mounting | Soldered | Inserted into holes |

| Modifications | Difficult once manufactured | Easy to change |

| Durability | High, suitable for permanent use | Lower, better for temporary prototyping |

| Size | Can be very compact | Larger, more spread out |

| Cost | Higher for design and fabrication | Low cost boards and reusable components |

| Skill Level | More advanced, requires PCB Design and soldering | Beginner-friendly, no special tools or skills needed |

| High Frequency Capability | Suitable for high frequency circuits | Problematic due to capacitance and inductance |

When to Use a PCB vs Breadboard

With those differences in mind, here are some recommendations for when it’s best to use a PCB or a breadboard:

Use a PCB if:

- You need a compact, durable, and permanent circuit

- The circuit design is finalized and ready for fabrication

- You are making multiples of the same circuit

- The circuit will be used in a commercial product

- You are comfortable with PCB design and have access to fabrication services

Use a breadboard if:

- You are a beginner learning circuits

- You need to experiment with the circuit design and make modifications

- The circuit is temporary or just for proof of concept

- You want to quickly test components or a small circuit

- Cost and time are concerns and you can’t justify fabricating a PCB

Of course, more complex projects may use a combination, such as starting with a breadboard to test the circuit design and then moving to a PCB for the final product. The right choice between PCB vs breadboard depends on your specific circuit needs and constraints.

Frequently Asked Questions (FAQ)

1. Can a breadboard circuit be converted to a PCB?

Yes, once you have a working circuit on a breadboard, you can translate that design into a schematic and PCB Layout to have it made into a printed circuit board. There is software available to help with this process.

2. Are there other prototyping methods besides breadboards?

Prototyping can also be done using other methods such as perfboard (a board with a grid of holes that is more durable than a breadboard but requires soldering) or wire-wrapping (making connections by wrapping wire around component leads). However, breadboards are one of the most common and beginner-friendly prototyping options.

3. How long does it take to get a PCB made?

The time to fabricate a PCB varies based on the complexity of the design and the service you use. Some quick-turn PCB Services can produce boards in a few days, while more complex designs or larger batches may take several weeks. It’s important to plan ahead and allow sufficient time for manufacturing.

4. Are there different types of PCBs?

Yes, PCBs come in different varieties based on the number of layers, the material used, and other features. Some common types are:

- Single layer – copper traces on one side of the board only

- Double layer – copper on both sides of the board

- Multi-layer – alternating layers of conducting and insulating material for more complex circuits

- Flexible – using a flexible insulating material for circuits that need to bend or fit into tight spaces

The type of PCB needed depends on the specific circuit requirements and operating conditions.

5. Can SMD components be used on a breadboard?

Surface mount devices (SMDs) are very small components that are designed to be soldered directly onto a PCB. While it is possible to use SMDs on a breadboard by soldering them to special adapters that plug into the breadboard holes, it is not very convenient. If your circuit will use many SMDs it’s better to design it as a PCB.

In conclusion, understanding the differences between PCBs and breadboards allows you to make an informed choice about the best construction method for your electronic circuits. While breadboards offer convenience and flexibility for prototyping and testing, PCBs provide a robust and compact solution for finished products. By weighing the advantages and limitations of each approach and considering the needs of your specific project, you can select the optimal balance of cost, durability, and ease of use. With the right tools and techniques, you can bring your circuit ideas to life using either PCBs or breadboards.

Leave a Reply