Introduction

Printed circuit boards (PCBs) are the backbone of electronic devices. They provide the interconnections between components and integrate circuits into functional products. However, PCBs can be vulnerable to mechanical stresses like vibration, shock, and flexing. These forces can cause trace fractures, pad lifting, and other reliability issues.

PCB stiffeners are support structures added to the PCB to reinforce it against mechanical stresses. They help prevent board flexing and strengthen solder joints. Stiffeners allow PCBs to withstand greater forces, enhancing product durability and reliability. This article will examine when and how to use PCB stiffeners to create robust, long-lasting circuit boards.

When to Use a PCB Stiffener

There are several situations where utilizing a stiffener is recommended or even required:

Large or Thin PCBs

Larger PCBs are more prone to flexing and bowing when handled or during assembly. Thinner boards are also more pliable. Stiffeners help strengthen these boards and prevent warpage or cracks. They are commonly used on PCBs larger than 100 x 100 mm or with a thickness under 1.6 mm.

High Component Density

Boards with many tall components, like connectors or capacitors, are prone to flexing. The components concentrate mechanical stresses onto small areas. Stiffeners help distribute these forces across the whole board. They are useful when there are >100 components per square inch.

Exposed to Vibration or Shock

Devices like handheld electronics or automotive electronics experience frequent vibrations. PCBs in these products need reinforcement against dynamic forces. Stiffeners help dampen vibrations and prevent fractures. They are necessary for electronics in high vibration environments.

Federally Regulated Products

Some industries like defense and aerospace have mandated standards for PCB stiffness. For example, MIL-STD-275 details stiffener requirements for military electronics. Using stiffeners ensures designs meet federal regulations.

High-Reliability Products

Mission-critical electronics like medical devices demand high reliability and durability. Adding stiffeners provides extra mechanical reinforcement as a conservative design choice. They help ensure long operational life for high-reliability products.

In summary, PCB stiffeners should be utilized whenever a board may be exposed to flexing, warpage, or dynamic stresses in its application. They provide inexpensive insurance against mechanical failure.

Stiffener Materials and Design

There are two main options when selecting a PCB stiffener material:

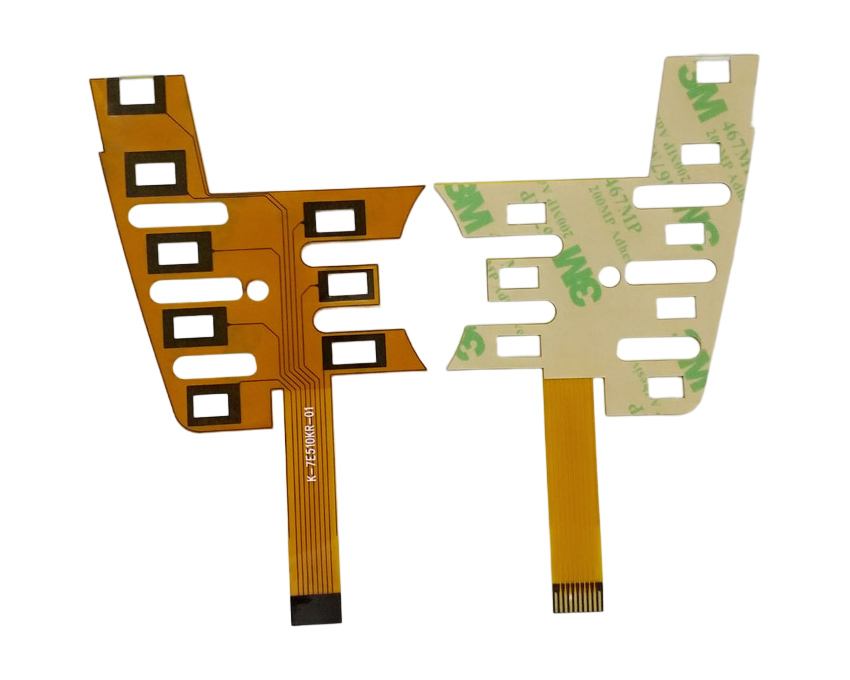

Plastic: such as FR4, PET, acrylic, PVC, and polycarbonates. Plastics are inexpensive and easily formed into shapes. However, their stiffness is temperature dependent. They become soft at higher temperatures.

Metal: such as steel, aluminum, copper, and brass. Metals provide excellent stiffness and remain rigid at high temps. However, they are heavier and more costly than plastics. Some may corrode over time.

The optimal material depends on cost, weight, max temperature, and other requirements. FR4 and aluminum provide a good cost/performance balance for most applications.

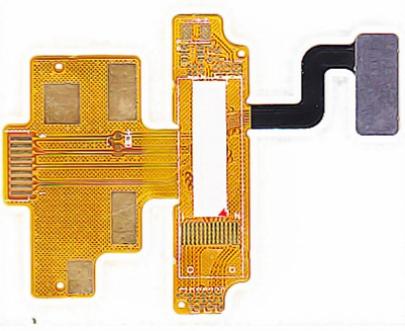

The stiffener shape can vary widely. Here are some common design forms:

- Flat panel – Simple flat plate attached to PCB surface. Easy to manufacture.

- Enclosing frame – Surrounds board perimeter. Good for thin/flexible PCBs.

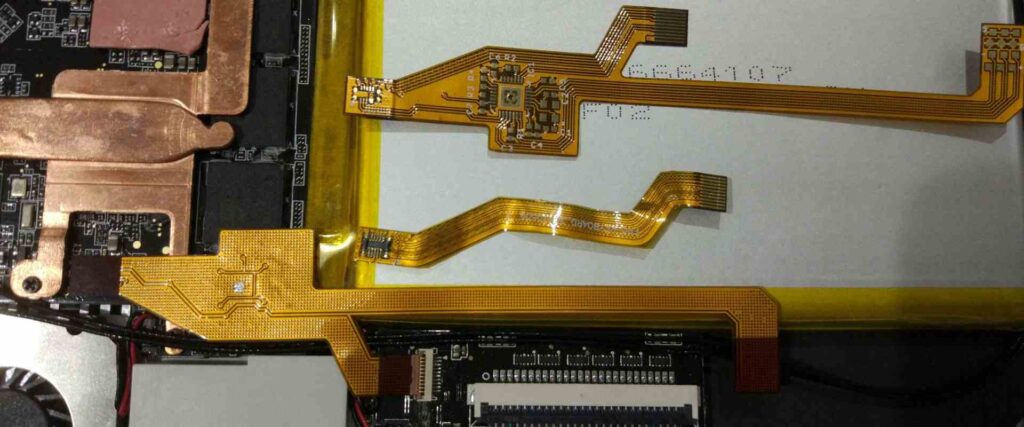

- Beams – Runs under components rows. Provides localized support.

- Ribs – Cross beams for targeted reinforcement. Help distribute stresses.

- Metal backplate – Plate covering entire backside. Maximum stiffness and shielding.

Ideally, stiffeners should:

- Be located behind tallest components

- Span areas prone to bending

- Have cutouts to allow access to PCB features

- Be affixed securely using adhesive or mechanical means

By tailoring the material, shape, and location, stiffeners can be designed to suit the specific reinforcement needs of the PCB application.

Best Practices for Implementation

Here are some guidelines to ensure stiffeners are implemented effectively:

- Simulate stresses – Use FEA tools early in design to identify weak points needing reinforcement.

- Attach securely – Use thick adhesive or solder if possible. Ensure no gaps between stiffener and PCB.

- Include cutouts – Allow access to components, test points, and other features blocked by the stiffener.

- Watch for shorts – Ensure metal stiffeners do not contact traces or pads, creating shorts. Use insulation if needed.

- Mind thermal expansion – Account for differential expansion of PCB vs. stiffener to avoid bowed boards.

- Work with your PCB manufacturer – They can help design optimal stiffener solutions tailored for your specific board.

- Test performance – Validate stiffener enhances reliability by testing vibration resilience, cycle life, drop impact, etc.

- Use selectively – Only use stiffeners where needed as they add cost and weight. Avoid over-engineering.

Following best practices for design and implementation will maximize the benefits of PCB stiffeners while avoiding potential pitfalls.

Effect on Manufacturing and Cost

Adding stiffeners does impact the PCB fabrication and assembly process:

- Increased layers – Additional mechanical layers are required to accommodate stiffener designs.

- More complex panelization – Board outlines must allow for stiffeners and their tolerances.

- Extra process steps – Material must be bonded to the PCB either during lamination or afterward.

- Altered thermomechanics – Stiffeners affect warp and stress patterns during lamination.

- Extra handling precautions – Boards with protruding stiffeners require more care in handling to avoid damage.

These factors will increase production time and cost. However, the rise is usually reasonable as stiffeners provide vital reinforcement. Typical increases are:

- PCB fabrication cost – 10-35% higher cost per board depending on stiffener complexity

- Assembly cost – Negligible impact

- Total BOM cost – Around 3-5% increase

This is quite affordable compared to the reliability enhancement and failure cost avoidance stiffeners provide. Discussing options with your PCB manufacturer early in the design process can help optimize cost.

Conclusion

PCB stiffeners provide vital reinforcement against mechanical stresses like shock, vibration, and flexing. They prevent failures and enhance product reliability. Stiffeners are recommended for large, thin, or high component density boards which will experience significant stresses. Careful design optimization and integration with manufacturing processes can mitigate the moderate cost increases stiffeners incur. The benefits of improved durability and reliability are well worth the extra expense in most applications. As PCBs become thinner and more densely populated, stiffeners are an increasingly essential element of robust electronic product designs.

Frequently Asked Questions

Here are some common questions about PCB stiffeners:

Q: How do I know if my PCB needs a stiffener?

A: Factors like large size (>100x100mm), thinness (<1.6mm), high component density (>100 per in2), vibrations, and flexing indicate stiffeners are recommended. FEA stress simulation can also identify weak areas needing reinforcement.

Q: What’s the best stiffener material to use?

A: Aluminum and FR4 fiberglass are good cost-effective options for most designs. Metals provide the greatest stiffness while plastics are lighter and cheaper. Select material based on temperature, weight, cost and stiffness needs.

Q: Where should I place stiffeners on the PCB?

A: Locate them under tall components like connectors which concentrate stresses. Also place along zones prone to bending or vibration. Stiffeners should span areas needing reinforcement but allow component access.

Q: How do stiffeners affect the PCB fabrication process?

A: Extra mechanical layers, panelization considerations, bonding steps, and handling precautions are needed. This typically increases cost by 10-35%. Work closely with your PCB manufacturer to optimize integration.

Q: Is it possible to overuse PCB stiffeners?

A: Yes, stiffeners should only be utilized where needed to avoid excessive cost and weight. Over-engineering with stiffeners everywhere wastes money without significant reliability improvements. Targeted placement is ideal.

Leave a Reply