Introduction to Zener Diodes

Zener diodes are a special type of semiconductor diode that are designed to operate in the reverse breakdown region. Unlike regular diodes, which are designed to block current flow in the reverse direction, Zener diodes are intended to breakdown and conduct current in the reverse direction when the voltage across them exceeds a certain threshold, known as the Zener voltage.

Zener diodes are widely used in electronic circuits for voltage regulation, overvoltage protection, and as voltage references. They are available in a range of Zener voltages, typically from a few volts to several hundred volts, and with power ratings ranging from a few milliwatts to several watts.

How Zener Diodes Work

When a reverse voltage is applied to a Zener diode, it initially behaves like a regular diode and blocks current flow. However, as the reverse voltage is increased, the electric field across the diode increases, and at a certain point, the field becomes strong enough to cause the diode to breakdown and start conducting current.

The breakdown voltage of a Zener diode is determined by the doping levels and the physical construction of the device. Once the breakdown voltage is reached, the voltage across the diode remains relatively constant, even as the current through the diode increases. This voltage regulation property is what makes Zener diodes useful in many applications.

The following table shows some common Zener diode voltage ratings and their typical applications:

| Zener Voltage | Typical Applications |

|---|---|

| 2.4V to 3.0V | Voltage references for low-voltage circuits |

| 3.3V to 5.1V | Voltage regulation for digital circuits |

| 6.2V to 12V | Voltage regulation for analog circuits |

| 15V to 200V | Overvoltage protection for power supplies |

Importance of Testing Zener Diodes

While Zener diodes are generally reliable devices, they can fail due to overcurrent, overheating, or manufacturing defects. A faulty Zener diode can cause circuit malfunction, damage to other components, or even pose a safety hazard in some cases.

Therefore, it is important to test Zener diodes before using them in a circuit, especially if they are critical components in the design. Testing can help identify faulty or out-of-spec devices, ensuring that only good quality components are used in the final product.

Zener Diode Tester Circuit

A Zener diode tester is a simple circuit that can be used to measure the breakdown voltage and leakage current of a Zener diode. The tester can be built using readily available components and can be a valuable tool for hobbyists, technicians, and engineers who work with Zener diodes.

Circuit Diagram

The following is a schematic diagram of a basic Zener diode tester circuit:

+-----+-----+

| | |

+-+ +-+ +-+

| | | | | |

| | | | | |

++-+ +-+ +-++

|R1 D1 R2|

| |

+------+------+

|

|

+-+

| |

| | Zener

+-+ Diode

| | Under

| | Test

+-+

|

|

+------+------+

| |

+-+ +-+

| | | |

| | | |

++-+ +-++

|R3 R4|

| |

+-------+-------+

|

|

+-+

| |

| |

++-+

|mA|

+--+

The circuit consists of the following components:

- R1, R2: Current limiting resistors

- D1: Protection diode

- R3, R4: Voltage divider resistors

- mA: Milliammeter

Component Selection

The values of the components in the Zener diode tester circuit depend on the range of Zener voltages and currents that need to be tested. Here are some guidelines for selecting the components:

-

R1, R2: These resistors limit the current through the Zener diode under test. The value of R1 should be chosen to allow a maximum current of around 10-20 mA through the Zener diode, while R2 should be around 10 times the value of R1. For example, for testing Zener diodes up to 20V, R1 can be 1k ohm and R2 can be 10k ohm.

-

D1: This diode protects the milliammeter from reverse current flow. Any general-purpose silicon diode with a forward voltage drop of around 0.7V, such as 1N4148 or 1N914, can be used.

-

R3, R4: These resistors form a voltage divider that scales down the voltage across the Zener diode to a level suitable for measurement by the milliammeter. The values of R3 and R4 should be chosen to provide a full-scale reading on the milliammeter when the maximum expected Zener voltage is applied. For example, if the milliammeter has a full-scale deflection of 1 mA and the maximum Zener voltage to be tested is 20V, then R3 can be 20k ohm and R4 can be 1k ohm.

-

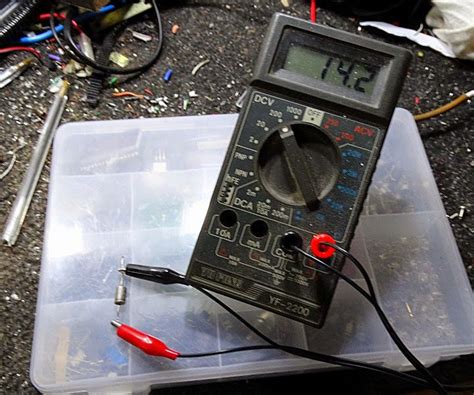

mA: The milliammeter should have a full-scale deflection of around 1 mA or less, and should be capable of withstanding the maximum expected Zener voltage. A digital multimeter with a current range of 1 mA or less can also be used instead of an analog milliammeter.

Construction

The Zener diode tester circuit can be easily constructed on a breadboard or a printed circuit board (PCB). Here are the steps for building the circuit:

- Assemble the components on the breadboard or PCB according to the schematic diagram.

- Double-check the component values and polarities before applying power to the circuit.

- Connect the Zener diode under test to the circuit, making sure to observe the correct polarity (cathode to ground).

- Apply a variable DC voltage to the circuit, starting from zero and gradually increasing until the Zener diode starts conducting.

- Monitor the voltage across the Zener diode using a voltmeter connected in parallel with the diode, and the current through the diode using the milliammeter.

- Record the Zener voltage and leakage current at the point where the diode starts conducting.

- Increase the voltage further and record the voltage and current readings at regular intervals until the maximum expected Zener voltage is reached.

- Disconnect the power supply and remove the Zener diode from the circuit.

Testing Procedure

Once the Zener diode tester circuit is constructed, it can be used to test Zener diodes of different voltage ratings and power dissipation capabilities. Here is a step-by-step procedure for testing a Zener diode:

- Select a Zener diode with a known voltage rating and power dissipation capability.

- Connect the Zener diode to the tester circuit, making sure to observe the correct polarity (cathode to ground).

- Set the variable DC voltage supply to zero.

- Gradually increase the voltage until the milliammeter shows a deflection, indicating that the Zener diode has started conducting.

- Record the voltage across the Zener diode using a voltmeter connected in parallel with the diode. This is the Zener voltage of the diode.

- Record the current through the Zener diode as indicated by the milliammeter. This is the leakage current of the diode.

- Increase the voltage further in small steps and record the voltage and current readings at each step.

- Continue increasing the voltage until the maximum expected Zener voltage is reached or the power dissipation limit of the diode is exceeded.

- Disconnect the power supply and remove the Zener diode from the circuit.

- Compare the measured Zener voltage and leakage current with the manufacturer’s specifications for the diode. If the measured values are within the specified tolerance range, the diode is good. If the values are outside the range, the diode may be faulty or degraded.

The following table shows an example of the data that can be collected during a Zener diode test:

| Voltage (V) | Current (mA) |

|---|---|

| 0 | 0 |

| 2.5 | 0.01 |

| 5.0 | 0.05 |

| 7.5 | 0.5 |

| 10.0 | 5.0 |

| 12.5 | 15.0 |

| 15.0 | 25.0 |

From the data, it can be seen that the Zener diode starts conducting at around 7.5V, which is its Zener voltage. The leakage current at this voltage is around 0.5 mA, which is within the typical range for most Zener diodes. As the voltage is increased further, the current through the diode increases rapidly, indicating that the diode is operating in the breakdown region.

Interpreting Test Results

The results obtained from testing a Zener diode using the tester circuit can be used to determine the quality and reliability of the diode. Here are some guidelines for interpreting the test results:

Zener Voltage

The measured Zener voltage should be within the specified tolerance range for the diode. Most Zener diodes have a tolerance of ±5% or ±10% of the nominal voltage. For example, a 10V Zener diode with a ±5% tolerance should have a measured Zener voltage between 9.5V and 10.5V.

If the measured Zener voltage is significantly higher or lower than the nominal value, it may indicate that the diode is faulty or degraded. A higher than expected Zener voltage may be due to contamination or defects in the semiconductor material, while a lower than expected voltage may be due to excessive leakage current or damage to the diode junction.

Leakage Current

The leakage current of a Zener diode is the small amount of current that flows through the diode when the applied voltage is less than the Zener voltage. The leakage current is typically in the range of a few microamps to a few milliamps, depending on the diode type and rating.

The measured leakage current should be within the specified range for the diode. If the leakage current is significantly higher than expected, it may indicate that the diode is faulty or degraded. High leakage current can cause excessive power dissipation and overheating of the diode, leading to premature failure.

Breakdown Characteristics

The breakdown characteristics of a Zener diode refer to the way in which the current through the diode increases as the voltage is increased beyond the Zener voltage. In a good quality Zener diode, the current should increase smoothly and rapidly once the breakdown voltage is reached, without any sudden changes or fluctuations.

If the breakdown characteristics of the diode are erratic or inconsistent, it may indicate that the diode is faulty or degraded. Erratic breakdown can cause noise, instability, and unpredictable behavior in the circuits where the diode is used.

Power Dissipation

The power dissipation of a Zener diode is the product of the voltage across the diode and the current through the diode. The maximum power dissipation rating of the diode depends on its package type and thermal characteristics.

During testing, the power dissipation of the diode should be kept within the rated limit to avoid damage or overheating. If the power dissipation exceeds the rated value, the diode may fail catastrophically or degrade over time.

The following table shows the maximum power dissipation ratings for some common Zener diode package types:

| Package Type | Maximum Power Dissipation |

|---|---|

| DO-35 | 500 mW |

| DO-41 | 1 W |

| SOD-123 | 200 mW |

| SOT-23 | 250 mW |

| TO-92 | 500 mW |

Troubleshooting and Safety

When using the Zener diode tester circuit, there are a few potential issues that may arise and some safety precautions that should be taken. Here are some troubleshooting tips and safety guidelines:

Troubleshooting

- If the milliammeter shows no deflection when the voltage is increased, check the connections and polarities of the components in the circuit. Make sure the Zener diode is connected correctly and the power supply is functioning properly.

- If the measured Zener voltage or leakage current is significantly different from the expected value, double-check the component values and the settings of the variable voltage supply. Make sure the voltage and current ranges of the meters are appropriate for the diode being tested.

- If the Zener diode gets hot or starts to smoke during testing, immediately disconnect the power supply and allow the diode to cool down. The diode may be faulty or the power dissipation limit may have been exceeded.

Safety

- Always wear safety glasses when working with electronic circuits, especially when dealing with high voltages or currents.

- Never touch the exposed leads of the Zener diode or any other component in the circuit while the power supply is on. Use insulated tools and probes to make connections and adjustments.

- Keep the work area clean and organized, and avoid cluttering the bench with unnecessary items that may cause short circuits or other hazards.

- When testing high-power Zener diodes, use a heat sink or other means of dissipating the excess heat generated by the diode. Avoid touching the diode or the heat sink during testing, as they may be hot enough to cause burns.

- Dispose of faulty or damaged Zener diodes properly, following the local regulations for electronic waste disposal. Do not throw them in the regular trash or leave them lying around, as they may pose a safety or environmental hazard.

Conclusion

A Zener diode tester is a simple but useful circuit that can be used to measure the breakdown voltage, leakage current, and other characteristics of Zener diodes. By building and using a Zener diode tester, hobbyists, technicians, and engineers can ensure that the Zener diodes they use in their projects are of good quality and meet the required specifications.

When constructing and using a Zener diode tester, it is important to select the appropriate components, follow the proper testing procedure, and interpret the results correctly. It is also important to troubleshoot any issues that may arise and follow the necessary safety precautions to avoid accidents or damage to the components.

By mastering the skills of Zener diode testing, one can become a more competent and effective electronics practitioner, and build more reliable and robust electronic circuits and devices.

FAQ

1. What is a Zener diode and how does it work?

A Zener diode is a special type of diode that is designed to operate in the reverse breakdown region, where it conducts current when the reverse voltage across it exceeds a certain threshold known as the Zener voltage. Zener diodes are used for voltage regulation, overvoltage protection, and as voltage references in electronic circuits.

2. Why is it important to test Zener diodes before using them in a circuit?

Testing Zener diodes before using them in a circuit is important to ensure that they are of good quality and meet the required specifications. Faulty or out-of-spec Zener diodes can cause circuit malfunction, damage to other components, or even pose a safety hazard in some cases. By testing Zener diodes, one can identify and reject faulty or substandard components and ensure that only reliable parts are used in the final product.

3. What are the main components of a Zener diode tester circuit?

The main components of a Zener diode tester circuit are:

- Current limiting resistors (R1 and R2) to limit the current through the Zener diode under test

- A protection diode (D1) to protect the milliammeter from reverse current flow

- Voltage divider resistors (R3 and R4) to scale down the voltage across the Zener diode to a level suitable for measurement by the milliammeter

- A milliammeter or a digital multimeter with a current range to measure the current through the Zener diode

4. How do you interpret the results of a Zener diode test?

The results of a Zener diode test can be interpreted by comparing the measured Zener voltage, leakage current, and breakdown characteristics with the manufacturer’s specifications for the diode. If the measured values are within the specified tolerance range, the diode is considered good. If the values are outside the range, the diode may be faulty or degraded. The power dissipation of the diode during testing should also be kept within the rated limit to avoid damage or overheating.

Leave a Reply