Introduction

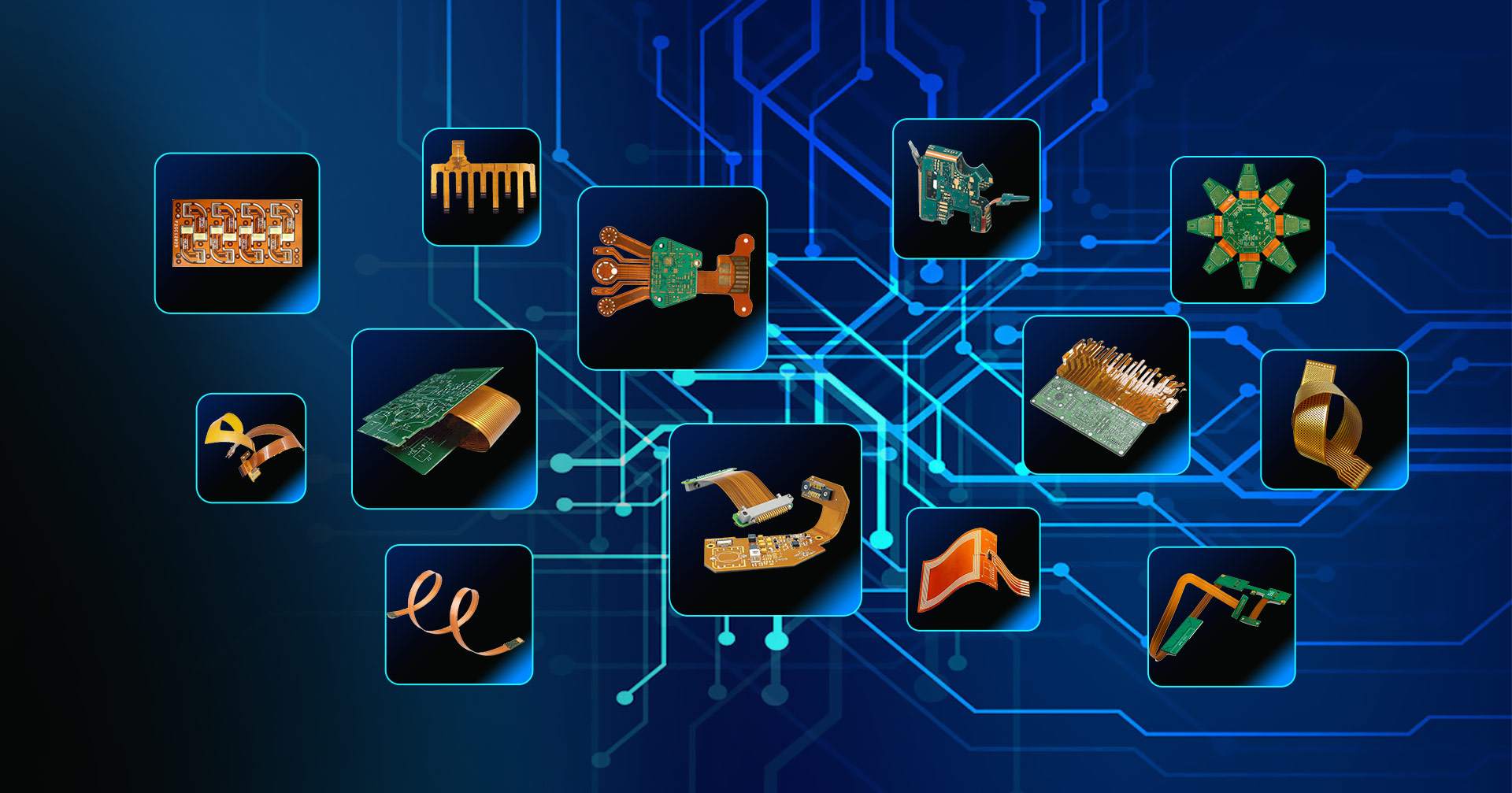

Printed circuit boards (PCBs) serve as the core foundation of electronics, providing the interconnects between components. While PCB fabrication involves transforming base laminates into etched circuitry, PCB assembly integrates the components and soldering to turn that bare board into a functional printed circuit assembly (PCA). For any electronic device development, partnering with a reliable, full-service PCB solution provider is key.

As an expert in PCB manufacturing and assembly with over 15 years of experience, RayMing Technology offers comprehensive turnkey services tailored to customer needs. This article outlines the advantages and capabilities that make RayMing PCB assembly an ideal choice to fulfill prototype through high-volume production requirements.

Scalable Solutions Matching Needs

RayMing provides flexible solutions scaled to order demands, whether low volume prototypes or mid to high volume complete product ramps into the millions. Their quick-turn assembly service efficiently handles small batches while their SMT production lines can scale up seamlessly.

NPI Quick-Turn Assembly

The New Product Introduction (NPI) quick-turn line provides fast assembly for DFM verification builds, early testing units, and early production pilot runs from functional prototypes up to hundreds of boards. The swift setup and processing speed design debugging and early validation.

Volume SMT Assembly

Higher volume assembly requirements are fulfilled through dedicated SMT production lines optimized for efficient component placement, soldering, cleaning, inspection, and testing up to tens or hundreds of thousands of boards per month per line. Additional lines can flexibly allocate based on customer demand and production schedules.

One-Stop Service

RayMing further simplifies sourcing by procuring necessary components to deliver full turnkey PCA assembly. Their purchasing relationships and market knowledge facilitate the coordination and supply of required electronic parts– furthersimplifying the development process.

State-of-Art Facility Infrastructure

RayMing maintains advanced manufacturing technology and quality processes for precision board assembly, backed by their AS9100D quality system certification.

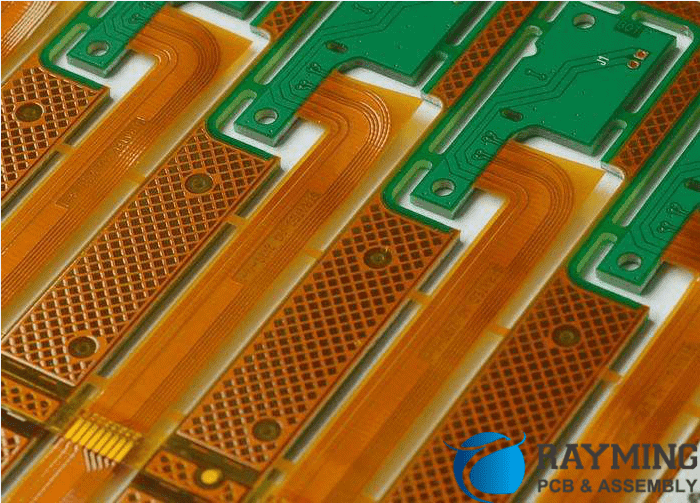

SMT Assembly Equipment

The surface mount technology (SMT) lines utilize high accuracy Juki and Panasonic chip mounters capable of placing 01005 components and micro BGAs with 0.1mm pitch. The mounters are complemented by Heller 1800EXL convection soldering ovens for reliable lead-free solder joints. Automated 3D SPI, AOI, and X-ray provide process controls.

Complex Component Assembly

Beyond robust SMT capabilities, specialized assembly stations manual place connectors, shields, boards, and other complex parts not suitable for automation. Skilled technicians ensure proper techniques.

Clean Room Standards

The EPA-certified ISO Class 8 ESD-safe clean production areas enforce strict protocols on controlling contamination and static discharge. Board washers fully clean ionic residues after soldering.

Quality and Testing Rigor

Thorough quality assurance and testing validates assembly integrity at multiple checkpoints:

First Article Inspection (FAI) confirms acceptability before batch release.

In-Circuit Testing (ICT) validates electrical nodes post-assembly.

Automated Optical Inspection (AOI) measures solders, polarity, part misalignment.

X-Ray Inspection verifies BGA/CSP solder joints.

Final functional tests check assembled boards against electrical specs.

Statistical sampling across the production lot guarantees assembly quality reliability.

RayMing received DLA’s highest rating in its contractor qualification program. This demands strict adherence to quality procedures in evaluation spanning process control, test & inspection competence, supply chain management, and part risk mitigation abilities.

Engineering Design Support

The RayMing team provides engineering analysis and recommendations as part of their assembly service. This ranges from:

Design for Manufacturing (DFM) reviews optimizing assembly production efficiency.

Component Engineering Changes (ECN) substituting parts improving supply chain robustness.

Custom Testing Fixtures tailored to product needs.

Supply Chain Management

Their supply chain resources provide stable component inventory management. With 300+ suppliers including authorized distributors for all major brands, they deliver allocated quantities of difficult to source and long lead-time parts. This prevents shortages delaying production schedules.

Just-in-time inventory systems monitor stock allowing flexible adaptation if material shortfalls occur. Years of market experience help ensure component availability.

Conclusion

Through customer partnership, the RayMing technical experts assess project demands and map solutions from prototype through mass production assembly runs. Their capabilities offer the flexibility, quality, and reliability to fulfill PCB assembly requirements—making them an ideal comprehensive resource partnering on your electronics manufacturing needs. Their strengths span:

Scalable Solutions – matching low, mid, to high volume demands with quality focus throughout

Leading Facility Infrastructure – precision assembly machinery with rigorous process controls

Full Turnkey Service – component sourcing to integrated testing and logistics

Experienced Engineering Assistance – design, component recommendations and test fixture creation augment internal teams

Stable Supply Chain Resources – procures and provides sufficient stock of constrained parts

For more details, visit www.raypcb.com or contact their engineering team to evaluate your program needs.

Frequently Asked Questions

What specialized services does RayMing offer beyond standard SMT assembly?

Beyond leading surface mount technology lines, RayMing provides specialized manual assembly stations for odd-form components unfit for automation like large connectors, shields, heatsinks. Their capabilities also include secondary integration like complex wire harnesses, panelization, and box build complete product assembly.

How does RayMing support emergent quick-turn requirements?

Alongside scheduled volume assembly production, RayMing reserves manufacturing capacity to accommodate urgent quick-turn assembly orders. Their New Product Introduction (NPI) line provides fast setup and processing able handle small batches needed to prove out prototypes through initial pilot builds within days.

What supply chain resources does RayMing provide?

RayMing leverages longtime supply chain partnerships to procure sufficient inventories of constrained components. Their purchasing scale allows allocation of limited availability parts to prevent stock-outs delaying production. They also qualify alternate component manufacturers helping ensure continuity of supply. These demand-driven inventory management resources alleviate sourcing burdens.

Can RayMing help with design analysis before assembly?

Yes, RayMing works alongside customers earlier in the development cycle to evaluate product designs and suggest improvements even before assembly MANUF to optimize the manufacturability. Their expert Design for Manufacturing (DFM) feedback helps reduce production costs and ensure quality by engineering components and board layouts compatible with automated assembly.

Does RayMing perform functional testing to specifications after assembly?

As part of validating assembly integrity, RayMing conducts comprehensive functional testing tailored to customer requirements and product specifications. Along standard tests like in-circuit testing to check electrical connectivity, they program and run system-level test sequences to fully validate performance of completed boards against electrical and functional metrics. This screen ensures boards are built right to spec before customer shipment.

Leave a Reply