Introduction

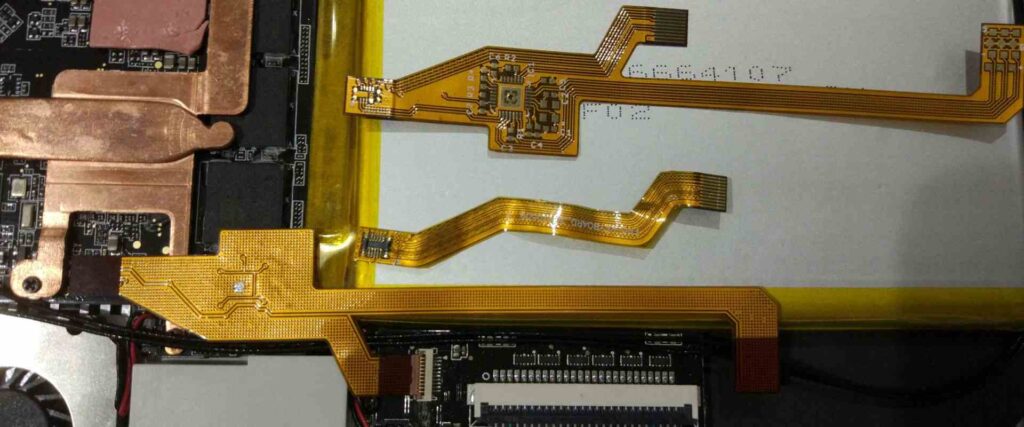

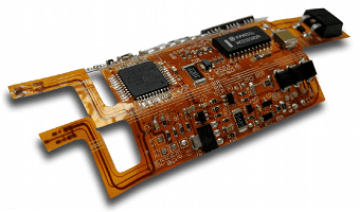

In the realm of electronics assembly and repair, desoldering plays a crucial role in maintaining, modifying, or reworking printed circuit boards (PCBs). Whether you’re a professional technician, hobbyist, or engineer, understanding the temperature requirements for effective desoldering is essential to ensure safe and successful component removal or replacement.

This comprehensive article delves into the intricate world of desoldering temperatures for PCBs, exploring the various factors that influence the ideal temperature range, the different desoldering techniques, and the potential risks and precautions associated with improper temperature control.

Understanding Solder Alloys and Melting Points

Before discussing desoldering temperatures, it’s essential to understand the composition and melting points of the solder alloys commonly used in PCB assembly. Solder is a fusible metal alloy that melts at a relatively low temperature, allowing it to create strong metallic bonds between components and PCB pads.

Common Solder Alloys and Their Melting Points

The most widely used solder alloys in electronics manufacturing are:

- Lead-based Solder (Sn63/Pb37): This alloy consists of 63% tin (Sn) and 37% lead (Pb) and has a melting point of approximately 183°C (361°F).

- Lead-free Solder (SAC305): As the name implies, this solder is lead-free and is composed of 96.5% tin (Sn), 3% silver (Ag), and 0.5% copper (Cu). It has a melting point range of 217°C to 221°C (423°F to 430°F).

It’s important to note that while lead-based solders have been widely used in the past, there has been a global shift towards lead-free solders due to environmental and health concerns associated with lead exposure.

Factors Affecting Solder Melting Points

Several factors can influence the melting point of solder alloys, including:

- Alloy Composition: The melting point is directly related to the specific composition of the solder alloy. Different ratios of tin, lead, silver, copper, and other metals will result in varying melting points.

- Impurities: The presence of impurities, even in small amounts, can affect the melting point of a solder alloy. Impurities can be introduced during the manufacturing process or through contamination during use.

- Thermal History: The thermal history of the solder joint, including the number of reflow cycles and the maximum temperatures experienced, can influence the melting point due to metallurgical changes in the alloy.

It’s crucial to consider these factors when determining the appropriate desoldering temperature, as they can impact the efficiency and safety of the process.

Desoldering Techniques and Temperature Requirements

Several desoldering techniques are commonly used in the electronics industry and hobbyist communities, each with its own temperature requirements and considerations.

Soldering Iron Desoldering

One of the most common and accessible desoldering methods is the use of a soldering iron. This technique involves applying heat directly to the solder joint using a soldering iron tip, allowing the solder to melt and facilitating component removal.

Temperature Requirements for Soldering Iron Desoldering

- Lead-based Solder (Sn63/Pb37): For effective desoldering of lead-based solder, the soldering iron tip temperature should be in the range of 315°C to 370°C (600°F to 700°F).

- Lead-free Solder (SAC305): Lead-free solder requires higher temperatures due to its higher melting point. The recommended soldering iron tip temperature for desoldering SAC305 solder is typically between 370°C and 400°C (700°F and 750°F).

It’s essential to use a temperature-controlled soldering iron and adjust the temperature according to the specific solder alloy being desoldered. Overheating can lead to damage to the PCB or components, while insufficient heat can result in incomplete solder melting and difficult component removal.

Hot Air Rework and Desoldering Stations

Hot air rework and desoldering stations are commonly used in professional electronics repair and rework environments. These systems provide a focused stream of hot air to melt the solder and facilitate component removal or replacement.

Temperature Requirements for Hot Air Rework and Desoldering

- Lead-based Solder (Sn63/Pb37): For lead-based solder, the hot air temperature should typically be set between 260°C and 315°C (500°F and 600°F).

- Lead-free Solder (SAC305): Due to the higher melting point of lead-free solder, the hot air temperature should be set between 315°C and 370°C (600°F and 700°F).

It’s important to note that the hot air temperature should be carefully controlled and monitored, as excessive heat can damage sensitive components or the PCB itself. Additionally, the duration of hot air exposure should be minimized to prevent overheating and potential damage.

Desoldering Baths and Pots

Desoldering baths and pots are specialized tools that use molten solder or other heat transfer media to desolder components from PCBs. These methods are commonly used in high-volume manufacturing or repair environments.

Temperature Requirements for Desoldering Baths and Pots

- Lead-based Solder (Sn63/Pb37): For desoldering lead-based solder, the bath or pot temperature should be maintained between 210°C and 260°C (410°F and 500°F).

- Lead-free Solder (SAC305): The recommended temperature range for desoldering lead-free solder using baths or pots is typically between 260°C and 315°C (500°F and 600°F).

Proper temperature control and maintenance are crucial when using desoldering baths and pots, as overheating can lead to potential safety hazards and damage to components or the PCB.

Other Desoldering Methods

In addition to the techniques mentioned above, there are other desoldering methods that may require different temperature considerations, such as:

- Desoldering Wicks and Braid: These are copper or ceramic-based wicks that absorb molten solder. The temperature requirements are similar to those for soldering iron desoldering.

- Desoldering Pumps: Desoldering pumps use vacuum suction to remove molten solder. The temperature requirements align with the solder alloy being desoldered.

- Ultrasonic Desoldering: This method uses high-frequency vibrations to break the metallic bonds between the solder and the component leads or pads. The temperature requirements may vary depending on the specific equipment and process.

It’s essential to follow the manufacturer’s recommendations and industry best practices when using any desoldering method to ensure safe and effective desoldering.

Potential Risks and Precautions

While desoldering is a necessary process in electronics assembly and repair, it’s crucial to be aware of the potential risks associated with improper temperature control and to take the necessary precautions to ensure safety and prevent damage.

Overheating Risks

Overheating during the desoldering process can lead to several issues:

- Component Damage: Excessive heat can damage sensitive components, such as integrated circuits (ICs), capacitors, and other semiconductor devices, rendering them inoperable or reducing their lifespan.

- PCB Delamination: High temperatures can cause the layers of the PCB to separate, leading to delamination and potential circuit failure.

- Solder Mask Damage: The solder mask, which provides insulation and protection for the PCB, can become discolored, charred, or degraded when exposed to excessive heat.

- Toxic Fume Exposure: Overheating can release toxic fumes from the solder, flux, or PCB materials, posing health risks if proper ventilation or personal protective equipment (PPE) is not used.

To mitigate these risks, it’s essential to closely monitor and control the desoldering temperature, use appropriate tools and equipment, and follow recommended safety practices.

Underheating Risks

While overheating can be detrimental, underheating during the desoldering process can also lead to challenges and potential issues:

- Incomplete Solder Melting: If the temperature is too low, the solder may not melt completely, making it difficult or impossible to remove the component effectively.

- Prolonged Heating: Attempting to desolder at insufficient temperatures can lead to prolonged heating, which can still cause damage to the PCB or components.

- Increased Mechanical Stress: When solder is not fully melted, excessive mechanical force may be required to remove the component, potentially damaging the PCB pads or component leads.

To avoid these risks, it’s crucial to ensure that the desoldering temperature is adequate for the specific solder alloy being used and to follow recommended temperature ranges and guidelines.

Safety Precautions

When working with desoldering processes, it’s essential to prioritize safety and take the necessary precautions:

- Proper Ventilation: Ensure adequate ventilation or use a fume extraction system to prevent exposure to potentially harmful fumes and vapors.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as heat-resistant gloves, safety glasses, and a respirator or fume mask, to protect against burns, fumes, and debris.

- Fire Safety: Have a fire extinguisher readily available and follow proper fire safety protocols when working with high temperatures and flammable materials.

- Electrical Safety: Disconnect power sources and follow proper electrostatic discharge (ESD) procedures to avoid electrical hazards and potential damage to components.

- Tool Maintenance: Regularly maintain and calibrate desoldering tools and equipment to ensure accurate temperature control and safe operation.

- Training and Experience: Seek proper training and gain experience in desoldering techniques and safety practices to minimize risks and ensure successful outcomes.

By adhering to these safety precautions and following best practices, you can minimize the potential risks associated with desoldering processes and create a safe working environment.

FQA (Frequently Asked Questions)

- Q: Can I desolder lead-based and lead-free solder at the same temperature? A: No, lead-based and lead-free solder alloys have different melting points, and therefore require different desoldering temperatures. Lead-free solder typically requires higher temperatures compared to lead-based solder for effective desoldering.

- Q: What happens if I use a temperature that is too high for desoldering? A: Using a desoldering temperature that is too high can lead to various issues, such as component damage, PCB delamination, solder mask degradation, and the release of toxic fumes. It’s crucial to follow the recommended temperature ranges for the specific solder alloy being desoldered.

- Q: Can I use the same desoldering temperature for all components on a PCB? A: Not necessarily. While the solder alloy used on a PCB is typically consistent, some components may have different temperature tolerance levels. It’s essential to consult component specifications and adjust the desoldering temperature accordingly to avoid potential damage.

- Q: How can I determine the appropriate desoldering temperature for a specific PCB? A: The appropriate desoldering temperature depends on the solder alloy used on the PCB. If the solder alloy is known, you can refer to the recommended temperature ranges provided in this article or consult industry guidelines. If the solder alloy is unknown, you may need to perform tests or seek professional assistance.

- Q: What safety precautions should I take when desoldering? A: When desoldering, it’s crucial to prioritize safety by ensuring proper ventilation, wearing appropriate personal protective equipment (PPE), following fire safety protocols, practicing electrical safety, maintaining tools and equipment, and seeking proper training and experience in desoldering techniques and safety practices.

Conclusion

Determining the appropriate desoldering temperature for PCBs is a critical aspect of electronics assembly, repair, and rework processes. Understanding the melting points of different solder alloys, such as lead-based and lead-free solders, is essential for effective and safe desoldering.

Various desoldering techniques, including soldering iron desoldering, hot air rework, and desoldering baths or pots, have specific temperature requirements to ensure successful component removal without causing damage to the PCB or components.

While overheating can lead to risks such as component damage, PCB delamination, solder mask degradation, and toxic fume exposure, underheating can also result in incomplete solder melting and increased mechanical stress during component removal.

To mitigate these risks, it is crucial to follow recommended temperature ranges, closely monitor and control the desoldering temperature, and adhere to safety precautions such as proper ventilation, personal protective equipment (PPE), fire safety protocols, electrical safety practices, and regular tool maintenance.

By combining knowledge of solder alloy properties, desoldering techniques, and safety best practices, electronics professionals and hobbyists alike can ensure successful and safe desoldering processes, extending the lifespan and functionality of their PCBs and electronic devices.

Data Visualization

| Solder Alloy | Melting Point | Desoldering Technique | Temperature Range |

|---|---|---|---|

| Lead-based (Sn63/Pb37) | 183°C (361°F) | Soldering Iron | 315°C – 370°C (600°F – 700°F) |

| Lead-based (Sn63/Pb37) | 183°C (361°F) | Hot Air Rework | 260°C – 315°C (500°F – 600°F) |

| Lead-based (Sn63/Pb37) | 183°C (361°F) | Desoldering Bath/Pot | 210°C – 260°C (410°F – 500°F) |

| Lead-free (SAC305) | 217°C – 221°C (423°F – 430°F) | Soldering Iron | 370°C – 400°C (700°F – 750°F) |

| Lead-free (SAC305) | 217°C – 221°C (423°F – 430°F) | Hot Air Rework | 315°C – 370°C (600°F – 700°F) |

| Lead-free (SAC305) | 217°C – 221°C (423°F – 430°F) | Desoldering Bath/Pot | 260°C – 315°C (500°F – 600°F) |

This table summarizes the recommended temperature ranges for desoldering lead-based (Sn63/Pb37) and lead-free (SAC305) solder alloys using various desoldering techniques, such as soldering iron desoldering, hot air rework, and desoldering baths or pots. It serves as a quick reference guide for selecting the appropriate desoldering temperature based on the solder alloy and desoldering method.

Leave a Reply