Importance of the Shipment Date

The shipment date is important for several reasons:

-

Inventory Management: The shipment date helps businesses plan their inventory levels. By knowing when products will be shipped out, companies can ensure they have sufficient stock to fulfill orders without overstocking, which can tie up capital and increase storage costs.

-

Production Planning: Manufacturers rely on the shipment date to schedule their production runs. By aligning production with the expected shipment dates, companies can optimize their resources and avoid delays.

-

Customer Satisfaction: Customers expect to receive their orders within the promised timeframe. By providing accurate shipment dates and meeting those commitments, businesses can enhance customer satisfaction and build brand loyalty.

-

Cash Flow Management: The shipment date also impacts a company’s cash flow. Delayed shipments can result in delayed payments, which can strain a business’s financial health.

Factors Affecting the Shipment Date

Several factors can influence the shipment date:

Product Availability

The availability of the product is a primary factor in determining the shipment date. If the product is in stock, it can be shipped immediately. However, if the product needs to be manufactured or sourced from a supplier, the shipment date will depend on the production or procurement lead time.

Shipping Method

The shipping method also affects the shipment date. Faster shipping options, such as overnight or two-day delivery, will have shorter lead times compared to standard shipping methods. However, expedited shipping often comes at a higher cost.

Shipping Destination

The destination of the shipment can impact the shipment date. International shipments often require additional time for customs clearance and transportation, which can extend the lead time.

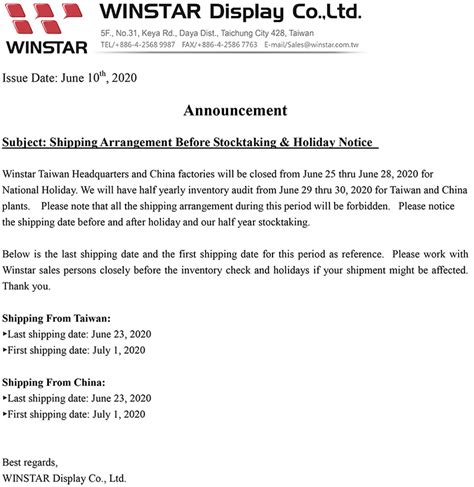

Holidays and Peak Seasons

Holidays and peak shopping seasons, such as Christmas or Black Friday, can also affect shipment dates. During these times, shipping carriers may experience higher volumes, which can lead to delays.

How to Determine the Shipment Date

Businesses can use several methods to determine the shipment date:

Supplier Agreements

Many companies have agreements with their suppliers that specify lead times for different products. By referring to these agreements, businesses can estimate the shipment date based on the product and quantity ordered.

Inventory Management Systems

Inventory management systems can provide real-time visibility into stock levels and expected shipment dates. These systems can also factor in lead times, safety stock levels, and other variables to provide accurate estimates.

Shipping Carrier Tools

Shipping carriers often provide tools and APIs that allow businesses to estimate shipping times based on the origin, destination, and shipping method. These tools can help companies provide accurate shipment dates to their customers.

Here’s an example of how shipping carrier tools can estimate shipment dates:

| Origin | Destination | Shipping Method | Estimated Shipment Date |

|---|---|---|---|

| New York, NY | Los Angeles, CA | Standard Ground | 5-7 business days |

| New York, NY | Los Angeles, CA | 2-Day Air | 2 business days |

| New York, NY | London, UK | International Priority | 3-5 business days |

Best Practices for Managing Shipment Dates

To effectively manage shipment dates, businesses should follow these best practices:

Set Realistic Expectations

It’s essential to set realistic expectations with customers regarding shipment dates. Overpromising and underdelivering can lead to frustration and lost business. Companies should factor in potential delays and provide conservative estimates to customers.

Communicate Proactively

If there are any changes to the expected shipment date, businesses should communicate proactively with their customers. Providing regular updates and being transparent about any issues can help mitigate customer dissatisfaction.

Monitor Shipping Performance

Businesses should monitor their shipping performance to identify any patterns or issues that may affect shipment dates. By tracking metrics such as on-time delivery rates and average lead times, companies can identify areas for improvement and take corrective action.

Partner with Reliable Suppliers and Carriers

Choosing reliable suppliers and shipping carriers is critical for meeting shipment dates. Companies should evaluate potential partners based on their track record of reliability, communication, and flexibility.

Shipment Date vs. Delivery Date

It’s important to note the difference between the shipment date and the delivery date. The shipment date is when the product leaves the seller’s facility, while the delivery date is when the product arrives at the customer’s location. The delivery date is affected by the shipping method and any potential delays in transit.

Here’s an example of the difference between shipment date and delivery date:

| Order Date | Shipment Date | Shipping Method | Estimated Delivery Date |

|---|---|---|---|

| 01/01/2023 | 01/02/2023 | Standard Ground | 01/07/2023 – 01/09/2023 |

| 01/01/2023 | 01/02/2023 | 2-Day Air | 01/04/2023 |

Impact of Late Shipments

Late shipments can have a significant impact on businesses and customers:

Lost Sales

Late shipments can result in lost sales if customers cancel their orders or choose to purchase from a competitor.

Increased Costs

Late shipments can increase costs for businesses, such as expedited shipping fees or penalties from customers.

Damage to Reputation

Consistently missing shipment dates can damage a company’s reputation and lead to negative reviews and lost future business.

Strategies for Mitigating Late Shipments

To mitigate the impact of late shipments, businesses can employ several strategies:

Buffer Inventory

Maintaining a buffer inventory can help businesses absorb unexpected delays and still meet customer demand. However, this strategy requires careful planning to balance the costs of holding inventory with the benefits of improved service levels.

Expedited Shipping

Offering expedited shipping options can help businesses recover from delays and still meet customer expectations. However, expedited shipping can be costly and may not be feasible for all orders.

Proactive Communication

As mentioned earlier, proactive communication with customers can help mitigate the impact of late shipments. By keeping customers informed and setting realistic expectations, businesses can maintain customer satisfaction even in the face of delays.

Frequently Asked Questions (FAQ)

- What is the difference between the shipment date and the delivery date?

The shipment date is when the product leaves the seller’s facility, while the delivery date is when the product arrives at the customer’s location. The delivery date is affected by the shipping method and any potential delays in transit.

- How can I track my shipment?

Most shipping carriers provide tracking numbers that allow customers to monitor the progress of their shipments. Customers can enter the tracking number on the carrier’s website or mobile app to get real-time updates on the status of their packages.

- What should I do if my shipment is delayed?

If your shipment is delayed, the first step is to contact the seller or supplier to get more information on the status of your order. They may be able to provide updated estimates or offer alternative solutions, such as expedited shipping or a refund.

- Can I change the shipping method after an order has been placed?

The ability to change the shipping method after an order has been placed depends on the seller’s policies and the status of the order. Some sellers may allow changes up until the order is processed, while others may not allow changes once the order is confirmed. It’s best to contact the seller directly to inquire about their policies.

- What factors can affect the shipment date?

Several factors can affect the shipment date, including product availability, shipping method, shipping destination, holidays, and peak seasons. Businesses should consider these factors when providing estimated shipment dates to customers and planning their inventory and production.

Conclusion

The shipment date is a critical component of the logistics and supply chain management process. By understanding the factors that influence shipment dates and employing best practices for managing them, businesses can improve their operations, enhance customer satisfaction, and ultimately drive growth. Effective communication, reliable partnerships, and proactive planning are key to ensuring that products are shipped on time and customers receive their orders as expected.

Leave a Reply