Introduction

Printed circuit boards (PCBs) come in a variety of colors, including the regal purple hue. But what exactly causes this purple coloration? In this comprehensive guide, we’ll explore the reasons behind purple PCBs, the types of boards and components that use this color, and the pros and cons of choosing it for your next PCB design. Whether you’re curious about PCB colors or looking to add some royal flair to your next circuit layout, read on to learn all about purple PCBs.

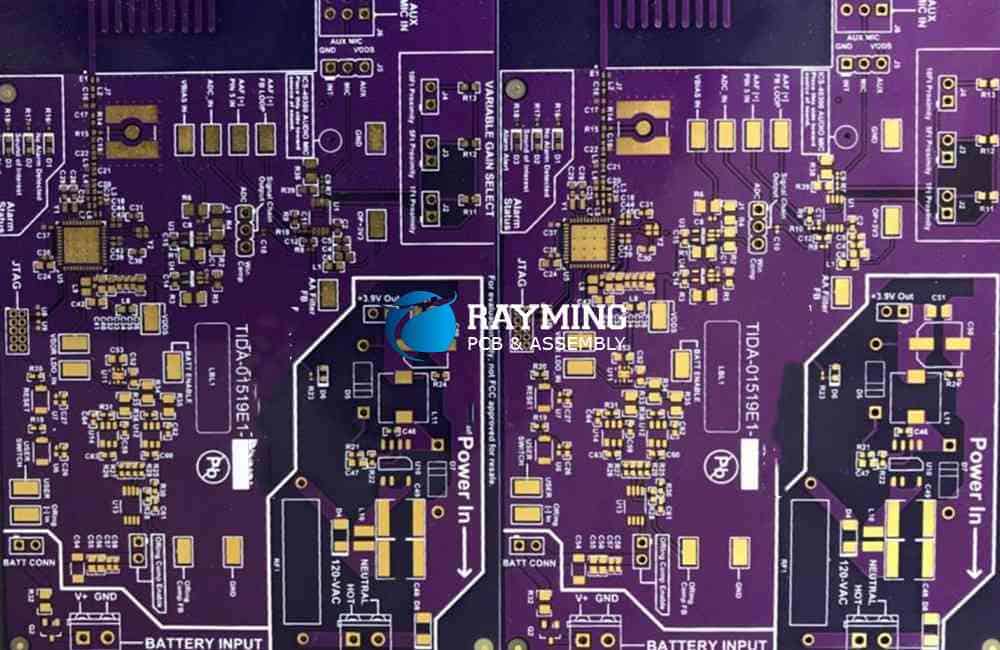

What Causes the Purple Color?

The vibrant purple color of PCBs stems from the base laminate material used in their construction. Most PCB laminates consist of layers of glass fiber cloth infused with an epoxy resin. The resin formulation provides the signature color. By adding violet organic dyes or pigments to this epoxy resin system, manufacturers can produce PCB laminate sheets ranging from pale lavender to deep violet shades.

Organic Dyes

Adding organic dyes is the most common method for achieving a purple tint. These dyes dissolve into the resin, producing an even distribution of color. The concentration and type of dye determines the exact hue. Low concentrations make pale purple laminates, while higher amounts create richer, darker purple boards.

Pigments

Manufacturers also use very fine purple pigment particles suspended in the epoxy resin. These particles reflect light waves in the violet wavelengths, generating the purple appearance. Adjusting the pigment level controls the saturation from light to dark purple. Pigments produce a more consistent color than dyes.

Hues of Purple PCBs

Purple PCBs encompass a wide spectrum of shades and intensities, ranging from faint lavender to deep eggplant. Here are some of the most common purple hues used in PCB fabrication:

Pale Lavender

With subdued undertones of violet, this very light purple shade has a slightly pink or lilac tint. It is one of the palest purple colors used for PCB laminates.

Lilac

Slightly deeper than lavender, lilac purple PCBs have a soft, elegant violet tone alongside hints of pink and blue. It creates a soothing pastel purple shade.

Medium Purple

This rich, saturated shade falls between light and dark purple. It has a vibrant, royal purple appearance that isn’t too overpowering.

Dark Purple

As the name suggests, dark purple PCBs have a deep, eggplant-like color with strong blue undertones alongside the dominant violet hue. This is one of the darkest purple shades you’ll see.

Deep Violet

Similar to dark purple but with redder undertones. This is an intense, regal shade associated with nobility and luxury.

Types of Boards Using Purple

While any PCB can use a purple laminate, certain types of circuit boards leverage this color more frequently. Here are some common purple PCB applications:

RF/Microwave PCBs

Many radio frequency and microwave PCBs rely on purple. At higher frequencies, lighter colors like white can produce undesirable reflections. The darker purple minimizes interference. It also helps differentiate RF/microwave boards from other PCB types.

Power Electronics

Darker purple laminates are popular for power electronic PCBs. The rich color masks any scorching from high voltage operation. Purple also designates these boards for high power applications.

Military/Aerospace

Defense and aerospace projects occasionally utilize purple circuit boards. The uncommon color makes these sensitive boards harder to counterfeit. The dark color also absorbs stray reflections that could interfere with onboard electronics.

Sensors

Light-sensitive sensor boards may adopt lighter purple shades. The subtle tint allows easy component tracing without excessive brightness interfering with sensors.

Novelty/Decorative

Some novelty and decorative circuit boards leverage purple purely for visual flair. Vibrant purple PCBs can complement products with similar color schemes. The unique color also attracts attention.

Components on Purple Boards

While the board defines the base color, the components populated on the PCB also impact its appearance. Here are some component considerations for purple boards:

- Light components like beige resistors, tan capacitors and silver connectors provide enough contrast against light purple laminates. But darker components show up better on richer shades.

- Dark components like black ICs, brown transistors and gray connectors pair well with darker purple PCBs. Light components would lack sufficient contrast.

- Colored components like red LEDs, blue switches and yellow connectors stand out nicely against any purple PCB shade. Vibrant secondary colors complement the base purple tone.

- White silkscreen offers good visibility against both light and dark purple laminates. Other light silkscreen colors like yellow also work.

- Black silkscreen provides bolder contrast on lighter purple boards. Switch to lighter silkscreens for darker purple to maintain legibility.

Benefits of Purple PCBs

Beyond visual appeal, purple PCBs offer several advantages:

Differentiation

The unique color clearly sets purple boards apart from more common green and red PCBs. This quickly identifies purple boards and their function.

EMI/RFI Shielding

Darker purple hues absorb electromagnetic interference (EMI) and radio frequency interference (RFI). This helps shield sensitive circuits.

Heat Tolerance

Most purple laminates withstand soldering heat and high power loads. This allows using purple in power electronics and other hot boards.

Low Outgassing

Properly cured purple epoxy resins avoid outgassing issues under vacuum environments for aerospace applications.

Density

Rich purple masks the underlying circuitry for added security in defense products. Unauthorized modifications become more apparent.

Challenges of Purple PCBs

However, purple PCBs also come with a few drawbacks:

Limited Contrast

The darker purple makes it harder to clearly see light components or silkscreen. Extra care is needed with markings.

Cost

Adding violet dyes or pigments increases material expenses. This makes purple laminates cost 10-25% more than black or green boards.

Lead Time

The unusual color means most manufacturers don’t keep purple PCB material in stock. Specific orders require longer fabrication lead times.

Color Consistency

If using dyes, color consistency can vary between material batches. Pigments offer enhanced consistency.

UV Fading

Purple dyes slowly fade with UV exposure. Pigments are more UV-stable for long term color retention.

Conclusion

With its regal color palette, the purple PCB offers a unique visual signature that highlights specialized boards. The distinctive hue arises from violet dyes or pigments within the epoxy resin laminate. Purple PCBs provide differentiation and EMI/RFI shielding but cost more than standard circuit board colors. When designed properly, purple PCBs fuse visual allure with functional performance.

Frequently Asked Questions

What exactly makes PCBs purple?

The purple color of PCB laminates stems from the addition of violet organic dyes or pigments into the epoxy resin used to infuse the fiberglass base layers. The concentration and type of dye/pigment controls the depth of purple color.

Does purple affect PCB performance?

Beyond visual distinction, purple PCBs offer some functional benefits. Darker shades provide EMI/RFI absorption while lighter ones allow minimal interference with light-sensitive components. But in general, purple does not directly impact electrical performance.

Are purple PCBs more expensive?

Yes, the cost of dying or pigmenting the epoxy resin makes purple PCB material run 10-25% higher than more standard laminate colors like green or black. The niche color also means fewer manufacturing runs, which increases cost.

Can components be easily soldered onto purple PCBs?

Most purple laminates use high temperature epoxy resins, so they withstand soldering heat without issue. But designers should select component colors with enough contrast against the particular purple PCB shade for easy assembly.

How durable is the purple color? Does it fade over time?

Organic dyes tend to slowly fade with UV exposure, temperature and humidity. But pigmented purple PCBs retain their color much better through harsh conditions and aging. Pigments offer the most durable purple shade.

Leave a Reply