Understanding Motor Drivers

A motor driver is an electronic circuit or module that is designed to control and drive motors. It receives control signals from a microcontroller or other control circuitry and translates them into appropriate power signals to drive the motors. Motor drivers are capable of handling the high current and voltage requirements of motors, which typically cannot be directly driven by the low-power signals from microcontrollers.

Types of Motor Drivers

There are several types of motor drivers available, each suitable for different types of motors and applications. Let’s explore some of the common types:

1. H-Bridge Motor Driver

An H-Bridge motor driver is one of the most widely used types of motor drivers. It consists of four switches arranged in an H-shaped configuration, allowing bidirectional control of a single motor. By controlling the switches, the H-Bridge can change the direction of current flow through the motor, enabling forward and reverse motion.

| Switch Configuration | Motor Direction |

|---|---|

| S1 & S4 ON, S2 & S3 OFF | Forward |

| S2 & S3 ON, S1 & S4 OFF | Reverse |

| S1 & S2 ON, S3 & S4 OFF | Brake |

| S3 & S4 ON, S1 & S2 OFF | Brake |

Examples of H-Bridge motor drivers include L293D, L298N, and TB6612FNG.

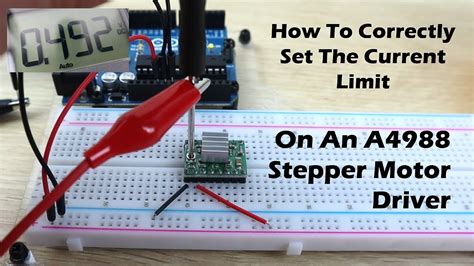

2. Stepper Motor Driver

Stepper motor drivers are specifically designed to control stepper motors, which are motors that move in precise increments or steps. Stepper motor drivers receive step and direction signals from the microcontroller and generate the appropriate sequence of pulses to drive the stepper motor. They often include features like microstepping for smoother motion and current control for optimizing torque.

Popular stepper motor drivers include A4988, DRV8825, and TMC2208.

3. Brushless DC (BLDC) Motor Driver

Brushless DC (BLDC) motors require specialized drivers due to their unique commutation requirements. BLDC motor drivers typically include a three-phase inverter circuit that generates the necessary voltage waveforms to drive the motor. They also incorporate features like speed control, position feedback, and regenerative braking.

Examples of BLDC motor drivers are IRFB7430, IRFB7540, and MC33035.

4. Servo Motor Driver

Servo motors are commonly used in robotics and automation applications for precise position control. Servo motor drivers generate the necessary pulse-width modulated (PWM) signals to control the position and speed of the servo motor. They often include additional features like position feedback and torque limiting.

Popular servo motor drivers include PCA9685 and Adafruit 16-Channel 12-bit PWM/Servo Driver.

Working Principle of Motor Drivers

The working principle of motor drivers revolves around the concept of power amplification and control. Motor drivers receive low-power control signals from the microcontroller and amplify them to drive the motors with the required current and voltage.

Here’s a simplified overview of how a typical motor driver works:

- The microcontroller sends control signals to the motor driver, specifying the desired direction, speed, or position of the motor.

- The motor driver interprets these control signals and generates the appropriate power signals to drive the motor.

- The power signals are amplified by the driver’s circuitry to provide the necessary current and voltage to the motor.

- The motor driver may also include protection features like over-current protection, thermal shutdown, and short-circuit protection to safeguard the motor and the driver itself.

Choosing the Right Motor Driver

When selecting a motor driver for your application, there are several factors to consider:

Motor Type and Specifications

The first step is to identify the type of motor you are using (DC motor, stepper motor, BLDC motor, or servo motor) and its specifications, such as voltage rating, current rating, and power requirements. Choose a motor driver that is compatible with your motor type and can handle its electrical characteristics.

Current and Voltage Ratings

Ensure that the motor driver’s current and voltage ratings match or exceed the requirements of your motor. The driver should be capable of delivering the necessary current to drive the motor at its rated load and speed.

Control Interface

Consider the control interface required by your application. Some motor drivers use simple digital inputs for direction and speed control, while others may require more advanced interfaces like PWM, SPI, or I2C. Choose a motor driver that is compatible with your microcontroller or control circuitry.

Additional Features

Look for additional features that may be beneficial for your application, such as:

– Microstepping for stepper motors

– Current limiting and protection

– Thermal shutdown

– Regenerative braking

– Diagnostic and fault detection

Size and Form Factor

Consider the physical size and form factor of the motor driver, especially if space is limited in your application. Some motor drivers are available in compact modules or integrated circuits, while others may require additional heat sinking or external components.

Interfacing Motor Drivers with Microcontrollers

Interfacing motor drivers with microcontrollers is a crucial aspect of motor control applications. Here are some common methods and considerations:

Pulse-Width Modulation (PWM)

PWM is a widely used technique for controlling motor speed and direction. By varying the duty cycle of the PWM signal, you can control the average voltage supplied to the motor, thereby controlling its speed. Many microcontrollers have built-in PWM functionality, making it easy to generate the necessary control signals for the motor driver.

Digital I/O

For simple on/off control or direction control, digital I/O pins of the microcontroller can be used. By setting the appropriate logic levels on the motor driver’s control pins, you can control the motor’s direction and enable/disable it.

Serial Communication

Some advanced motor drivers support serial communication protocols like SPI or I2C. These protocols allow for more complex control and monitoring of the motor driver, such as setting microstepping resolution, reading status registers, or configuring advanced features.

Analog Control

In some cases, motor speed can be controlled using analog signals. The microcontroller can generate an analog voltage using a digital-to-analog converter (DAC) or PWM with a low-pass filter, which is then fed into the motor driver’s speed control input.

Applications of Motor Drivers

Motor drivers find applications in a wide range of fields, including:

- Robotics and automation

- CNC machines and 3D printers

- Industrial control systems

- Automotive systems

- Home automation and IoT devices

- Medical devices and equipment

- Consumer electronics

Frequently Asked Questions (FAQ)

-

What is the difference between a motor driver and a motor controller?

A motor driver is a circuit or module that amplifies the control signals from a microcontroller to drive a motor. It focuses on the power electronics aspect of motor control. On the other hand, a motor controller is a more comprehensive term that encompasses the entire control system, including the microcontroller, feedback sensors, and control algorithms, in addition to the motor driver. -

Can a motor driver be used with any type of motor?

No, motor drivers are designed for specific types of motors. For example, an H-Bridge motor driver is suitable for DC motors, while a stepper motor driver is specifically designed for stepper motors. It’s important to choose a motor driver that matches the type and specifications of your motor. -

How do I determine the current rating required for my motor driver?

The current rating of the motor driver should be equal to or higher than the maximum current draw of your motor. Refer to the motor’s datasheet or specifications to determine its rated current. It’s a good practice to choose a motor driver with some headroom in terms of current rating to ensure reliable operation and avoid overheating. -

Can I use a single motor driver to control multiple motors?

It depends on the motor driver and the application. Some motor drivers, like the L298N, have multiple channels and can control two motors independently. However, if you need to control a large number of motors, you may need to use multiple motor drivers or opt for a more specialized solution like a motor driver array or a multi-channel motor controller. -

What are some common issues to watch out for when using motor drivers?

Some common issues to be aware of when using motor drivers include: - Overheating: Motor drivers can generate significant heat, especially when driving motors at high currents. Ensure proper heat dissipation and use heat sinks if necessary.

- Voltage spikes: Motors can generate voltage spikes when switching direction or during rapid deceleration. Use appropriate protection circuitry, such as flyback diodes, to suppress these spikes.

- Noise and electromagnetic interference (EMI): Motor drivers can generate electrical noise that may interfere with nearby electronic components. Use proper grounding, shielding, and decoupling techniques to minimize EMI.

- Overcurrent and short-circuit protection: Implement appropriate current limiting and short-circuit protection mechanisms to safeguard the motor driver and the motor from damage due to excessive current.

Conclusion

Motor drivers play a crucial role in enabling precise control and efficient operation of motors in various applications. By understanding the types of motor drivers, their working principles, and the factors to consider when selecting one, you can make informed decisions for your motor control projects.

When interfacing motor drivers with microcontrollers, consider the control methods that best suit your application, such as PWM, digital I/O, serial communication, or analog control. Pay attention to the electrical characteristics, protection features, and compatibility of the motor driver with your motor and control circuitry.

By leveraging the capabilities of motor drivers, you can unlock a wide range of possibilities in robotics, automation, and beyond. Whether you are building a robot, automating a manufacturing process, or creating an innovative IoT device, motor drivers provide the essential link between your control system and the motors that bring your ideas to life.

Leave a Reply