Introduction to PCBs and Their Significance

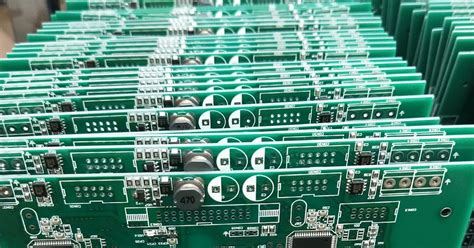

Printed Circuit Boards, commonly known as PCBs, have revolutionized the electronics industry since their inception. These small, green boards are the backbone of almost every electronic device we use today, from smartphones and computers to medical equipment and aerospace technology. PCBs have enabled the miniaturization of electronic components, making devices smaller, faster, and more efficient. In this article, we will delve into the fascinating history of PCBs, exploring their origins, development, and the impact they have had on our modern world.

The Early Days of Electronics and the Need for PCBs

The Advent of Electronics and the Challenges Faced

The history of PCBs is closely tied to the history of electronics itself. In the early 20th century, electronic devices were large, bulky, and often unreliable. They relied on point-to-point wiring, where each component was connected to another using individual wires. This method was time-consuming, prone to errors, and made it difficult to mass-produce electronic devices.

The Idea of a Printed Circuit

The concept of a printed circuit was first introduced by Austrian engineer Paul Eisler in the late 1930s. Eisler’s idea was to print the electrical connections onto an insulating board, eliminating the need for point-to-point wiring. However, due to the limitations of technology at the time, Eisler’s idea did not gain immediate traction.

The Wartime Development of PCBs

The Role of World War II in Accelerating PCB Development

It was during World War II that the development of PCBs truly took off. The war effort required the mass production of reliable electronic equipment, such as radios and radar systems. The United States Army and Navy began experimenting with printed circuit technology to improve the reliability and efficiency of their electronic devices.

The First PCBs and Their Applications

In 1943, the United States Army introduced the first operational PCB, used in the proximity fuze for anti-aircraft shells. This PCB was a simple single-sided board made of a ceramic substrate with printed silver conductors. The success of this application led to the widespread adoption of PCBs in military equipment throughout the war.

Post-War Advancements in PCB Technology

The Transition from Military to Commercial Use

After World War II, PCB technology began to transition from military to commercial applications. In the 1950s, the consumer electronics industry started to grow, and PCBs played a crucial role in making electronic devices more affordable and accessible to the general public.

The Introduction of Double-Sided and Multi-Layer PCBs

As electronic devices became more complex, the need for more sophisticated PCBs arose. In the 1960s, double-sided PCBs were introduced, allowing for the printing of circuits on both sides of the board. This development enabled the creation of more compact and efficient electronic devices.

The 1970s saw the introduction of multi-layer PCBs, which consist of multiple layers of printed circuits stacked and laminated together. Multi-layer PCBs allowed for even greater circuit density and complexity, paving the way for the development of advanced electronic devices.

The Rise of Computer-Aided Design (CAD) in PCB Development

The 1980s brought about a significant advancement in PCB design with the introduction of computer-aided design (CAD) software. CAD tools allowed engineers to design PCBs digitally, making the process faster, more accurate, and more efficient. This development greatly accelerated the pace of PCB innovation and made it possible to create increasingly complex designs.

The Modern Era of PCBs

The Impact of Miniaturization and Surface-Mount Technology (SMT)

In the 1990s and 2000s, the trend towards miniaturization in electronics continued to drive PCB development. The introduction of surface-mount technology (SMT) allowed for the placement of smaller components directly onto the surface of the PCB, reducing the overall size of electronic devices.

The Emergence of High-Density Interconnect (HDI) PCBs

As electronic devices became more sophisticated and compact, the need for even higher circuit density arose. High-density interconnect (HDI) PCBs emerged as a solution, featuring finer lines, smaller vias, and more layers than traditional PCBs. HDI PCBs have enabled the development of the ultra-compact and powerful electronic devices we use today, such as smartphones and tablets.

The Role of PCBs in the Internet of Things (IoT) and Industry 4.0

In recent years, PCBs have played a crucial role in the development of the Internet of Things (IoT) and Industry 4.0. IoT devices, which are connected to the internet and can communicate with each other, rely on compact and efficient PCBs to function. In the context of Industry 4.0, PCBs are essential components in smart factories, enabling the automation and optimization of manufacturing processes.

The Future of PCBs

Emerging Trends and Technologies in PCB Development

As we look to the future, several emerging trends and technologies are set to shape the development of PCBs. These include:

-

Flexible and stretchable PCBs: These innovative PCBs can bend and stretch, making them suitable for wearable electronics and other applications where flexibility is required.

-

3D printing of PCBs: Additive manufacturing techniques, such as 3D printing, are being explored as a means to create PCBs, potentially enabling the rapid prototyping and customization of electronic devices.

-

Embedded components: The integration of electronic components directly into the PCB substrate is becoming increasingly common, allowing for even greater miniaturization and functionality.

The Importance of Sustainability in PCB Manufacturing

As the demand for electronic devices continues to grow, the importance of sustainability in PCB manufacturing cannot be overstated. The electronics industry is exploring ways to reduce the environmental impact of PCB production, such as using eco-friendly materials, implementing recycling programs, and adopting green manufacturing processes.

The Continued Evolution of PCBs in Shaping Our Future

PCBs have come a long way since their inception, and they continue to evolve to meet the demands of our rapidly advancing technological landscape. As we move into the future, PCBs will undoubtedly play a crucial role in shaping the electronic devices and systems that will define our world.

Conclusion

The history of printed circuit boards is a testament to human ingenuity and the relentless pursuit of innovation. From their humble beginnings as a wartime necessity to their current status as the backbone of modern electronics, PCBs have transformed the way we live, work, and communicate. As we continue to push the boundaries of what is possible with electronic devices, the importance of PCBs will only continue to grow.

Frequently Asked Questions (FAQ)

1. What is a printed circuit board (PCB)?

A printed circuit board (PCB) is a flat board made of insulating material, such as fiberglass or plastic, with conductive pathways printed or etched onto its surface. These pathways connect electronic components, allowing them to function as a complete circuit.

2. When were PCBs first invented?

The concept of a printed circuit board was first introduced by Austrian engineer Paul Eisler in the late 1930s. However, it was during World War II that PCBs were first put into practical use, with the United States Army introducing the first operational PCB in 1943.

3. How have PCBs evolved over time?

PCBs have undergone significant advancements since their inception. Key milestones include the introduction of double-sided and multi-layer PCBs in the 1960s and 1970s, the rise of computer-aided design (CAD) in the 1980s, the impact of miniaturization and surface-mount technology (SMT) in the 1990s and 2000s, and the emergence of high-density interconnect (HDI) PCBs in recent years.

4. What role do PCBs play in modern electronics?

PCBs are the backbone of modern electronics, providing the foundation upon which electronic components are mounted and connected. They are essential in the development of a wide range of devices, from smartphones and computers to medical equipment and aerospace technology. PCBs have enabled the miniaturization and increased functionality of electronic devices, making them more efficient, reliable, and affordable.

5. What does the future hold for PCB technology?

The future of PCB technology is characterized by emerging trends and technologies, such as flexible and stretchable PCBs, 3D printing of PCBs, and embedded components. Additionally, sustainability is becoming increasingly important in PCB manufacturing, with the industry exploring eco-friendly materials and processes. As electronic devices continue to evolve, PCBs will play a crucial role in shaping our future.

| Year | Development |

|---|---|

| 1930s | Concept of printed circuits introduced by Paul Eisler |

| 1943 | First operational PCB used by the United States Army |

| 1950s | PCBs transition from military to commercial use |

| 1960s | Introduction of double-sided PCBs |

| 1970s | Introduction of multi-layer PCBs |

| 1980s | Rise of computer-aided design (CAD) in PCB development |

| 1990s | Impact of miniaturization and surface-mount technology |

| 2000s | Emergence of high-density interconnect (HDI) PCBs |

| 2010s | PCBs play a crucial role in IoT and Industry 4.0 |

| Future | Flexible PCBs, 3D printing, and embedded components |

Leave a Reply