What is an SMPS Circuit?

An SMPS circuit is a power supply that uses switching regulators to convert electrical power efficiently. Unlike linear power supplies, which use a transformer to step down the voltage and then regulate it using a linear regulator, SMPS circuits employ high-frequency switching techniques to regulate the output voltage.

The main components of an SMPS circuit include:

1. Rectifier

2. High-frequency transformer

3. Switching device (such as a MOSFET or BJT)

4. Output rectifier and filter

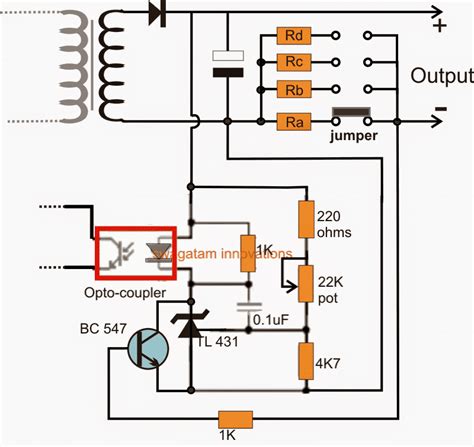

5. Feedback and control circuitry

How Does an SMPS Circuit Work?

The working principle of an SMPS circuit can be broken down into several stages:

-

Rectification: The input AC voltage is first rectified using a bridge rectifier and filtered using a capacitor to obtain a DC voltage.

-

High-frequency switching: The DC voltage is then fed to a switching device, typically a MOSFET or BJT, which is turned on and off at a high frequency (usually in the range of 20kHz to 1MHz). This high-frequency switching is controlled by a pulse-width modulation (PWM) signal generated by the control circuitry.

-

Voltage step-down: The high-frequency AC voltage from the switching device is then applied to the primary winding of a high-frequency transformer. The transformer steps down the voltage to the desired level on its secondary winding.

-

Output rectification and filtering: The stepped-down AC voltage is then rectified using a high-frequency rectifier (such as a Schottky diode) and filtered using a capacitor to obtain a smooth DC output voltage.

-

Feedback and regulation: A portion of the output voltage is fed back to the control circuitry, which compares it with a reference voltage. Based on the difference between the two, the control circuitry adjusts the PWM signal to maintain a constant output voltage despite variations in the input voltage or load current.

Types of SMPS Circuits

There are several types of SMPS circuits, each with its own unique characteristics and applications:

-

Buck converter: A buck converter, also known as a step-down converter, is used to reduce the input voltage to a lower output voltage. It is commonly used in battery-powered devices and voltage regulators.

-

Boost converter: A boost converter, also known as a step-up converter, is used to increase the input voltage to a higher output voltage. It is often used in applications where a higher voltage is required, such as LED drivers and automotive systems.

-

Buck-boost converter: A buck-boost converter can both step-down and step-up the input voltage, making it a versatile choice for applications with a wide range of input voltages.

-

Flyback converter: A flyback converter is a simple and cost-effective SMPS topology that uses a single switching device and a transformer with multiple windings. It is commonly used in low-power applications, such as mobile phone chargers and standby power supplies.

-

Forward converter: A forward converter is similar to a flyback converter but uses a separate winding for the output rectifier. It is more efficient than a flyback converter and is used in medium-power applications, such as computer power supplies and industrial equipment.

Here’s a table comparing the different types of SMPS circuits:

| SMPS Type | Input Voltage | Output Voltage | Efficiency | Applications |

|---|---|---|---|---|

| Buck | High | Low | High | Battery-powered devices, voltage regulators |

| Boost | Low | High | Medium | LED drivers, automotive systems |

| Buck-boost | Variable | Variable | Medium | Wide range of input voltages |

| Flyback | High | Low | Low | Mobile phone chargers, standby power supplies |

| Forward | High | Medium | High | Computer power supplies, industrial equipment |

Advantages of SMPS Circuits

SMPS circuits offer several advantages over linear power supplies:

-

High efficiency: SMPS circuits can achieve efficiencies of up to 95%, compared to around 50-60% for linear power supplies. This high efficiency translates to lower heat generation and smaller heatsinks, making SMPS circuits more compact and reliable.

-

Smaller size and weight: Due to their high efficiency and high-frequency operation, SMPS circuits require smaller transformers, inductors, and capacitors. This results in a more compact and lightweight design compared to linear power supplies.

-

Wide input voltage range: SMPS circuits can operate over a wide range of input voltages, making them suitable for applications with varying input conditions, such as battery-powered devices and industrial equipment.

-

Faster transient response: SMPS circuits have a faster transient response compared to linear power supplies, meaning they can quickly adapt to changes in the load current without causing significant voltage fluctuations.

-

Lower cost: Although SMPS circuits are more complex than linear power supplies, their high efficiency and smaller size often result in lower overall system costs, especially in high-volume applications.

Applications of SMPS Circuits

SMPS circuits find applications in a wide range of industries and products:

-

Consumer electronics: SMPS circuits are used in mobile phones, laptops, tablets, televisions, and other portable devices to provide efficient and compact power supplies.

-

Telecommunications: SMPS circuits are used in telecom equipment, such as routers, switches, and base stations, to provide reliable and efficient power supplies.

-

Industrial automation: SMPS circuits are used in industrial control systems, such as PLCs, HMIs, and motor drives, to provide stable and efficient power supplies in harsh environments.

-

Automotive: SMPS circuits are used in automotive electronics, such as infotainment systems, engine control units, and lighting systems, to provide efficient and reliable power supplies in a wide range of operating conditions.

-

Medical devices: SMPS circuits are used in medical equipment, such as patient monitors, defibrillators, and imaging systems, to provide safe and reliable power supplies that meet strict regulatory requirements.

Designing an SMPS Circuit

Designing an SMPS circuit involves several key considerations:

-

Selecting the appropriate topology: The choice of SMPS topology depends on factors such as the input voltage range, output voltage and current requirements, efficiency targets, and cost constraints.

-

Choosing the right components: The selection of components, such as the switching device, transformer, inductors, and capacitors, is critical to the performance and reliability of the SMPS circuit. Factors such as voltage and current ratings, switching frequency, and thermal management must be carefully considered.

-

Ensuring proper layout and grounding: The high-frequency nature of SMPS circuits makes them susceptible to electromagnetic interference (EMI) and noise. Proper PCB layout and grounding techniques, such as using short and wide traces, minimizing loop areas, and using ground planes, are essential to minimize these issues.

-

Implementing feedback and control: The feedback and control circuitry is responsible for maintaining a stable output voltage despite variations in the input voltage or load current. The choice of control scheme, such as voltage-mode or current-mode control, and the design of the compensation network are critical to the stability and transient response of the SMPS circuit.

-

Meeting safety and regulatory requirements: SMPS circuits must meet various safety and regulatory standards, such as UL, CE, and FCC, depending on the application and market. Considerations such as isolation, overcurrent protection, and EMI filtering must be incorporated into the design to ensure compliance.

Troubleshooting SMPS Circuits

Troubleshooting SMPS circuits can be challenging due to their complexity and high-frequency operation. Some common issues and their potential causes include:

-

No output voltage: This could be caused by a faulty switching device, transformer, or rectifier, or by a problem with the control circuitry.

-

Unstable output voltage: This could be caused by improper feedback compensation, noise in the control circuitry, or a faulty component in the power stage.

-

Overheating: This could be caused by excessive load current, inadequate heatsinking, or a faulty component, such as a shorted switching device or a leaky capacitor.

-

EMI problems: This could be caused by improper layout or grounding, inadequate filtering, or a faulty component, such as a noisy switching device or a damaged inductor.

When troubleshooting SMPS circuits, it is essential to use appropriate test equipment, such as oscilloscopes, voltage and current probes, and spectrum analyzers, and to follow safe working practices, as SMPS circuits can contain high voltages and currents.

FAQs

-

What is the difference between an SMPS and a linear power supply?

An SMPS uses high-frequency switching techniques to regulate the output voltage, while a linear power supply uses a transformer to step down the voltage and a linear regulator to control the output. SMPS circuits are more efficient, compact, and lightweight compared to linear power supplies. -

What are the main components of an SMPS circuit?

The main components of an SMPS circuit include a rectifier, high-frequency transformer, switching device (such as a MOSFET or BJT), output rectifier and filter, and feedback and control circuitry. -

What are the different types of SMPS topologies?

The different types of SMPS topologies include buck (step-down), boost (step-up), buck-boost, flyback, and forward converters. Each topology has its own unique characteristics and applications. -

What are the advantages of using an SMPS circuit?

The advantages of using an SMPS circuit include high efficiency, smaller size and weight, wide input voltage range, faster transient response, and lower overall system costs compared to linear power supplies. -

What are some common applications of SMPS circuits?

SMPS circuits are used in a wide range of applications, including consumer electronics, telecommunications, industrial automation, automotive, and medical devices. They provide efficient and reliable power supplies in various operating conditions and environments.

Conclusion

SMPS circuits have revolutionized the power supply industry, offering high efficiency, compact size, and wide input voltage range compared to traditional linear power supplies. Understanding the working principles, components, and design considerations of SMPS circuits is essential for engineers and technicians working in the electronics industry.

By selecting the appropriate topology, choosing the right components, ensuring proper layout and grounding, implementing effective feedback and control, and meeting safety and regulatory requirements, designers can create reliable and efficient SMPS circuits for a wide range of applications.

As technology continues to advance, SMPS circuits will play an increasingly important role in powering the electronic devices and systems that shape our modern world.

Leave a Reply