Understanding Sealed Lead Acid Batteries

Sealed lead acid batteries, also known as valve-regulated lead acid (VRLA) batteries, are maintenance-free, rechargeable batteries that offer several advantages over traditional flooded lead acid batteries. They are designed with a sealed case, which prevents the electrolyte from spilling and minimizes the release of gases during charging and discharging processes.

SLA batteries come in two main types:

-

Absorbed Glass Mat (AGM) Batteries: AGM batteries feature a fiberglass separator that absorbs the electrolyte, making them spill-proof and resistant to vibrations.

-

Gel Cell Batteries: Gel cell batteries use a gelled electrolyte, which provides excellent resistance to deep discharge and a longer lifespan compared to AGM batteries.

Characteristics of Sealed Lead Acid Batteries

| Characteristic | Description |

|---|---|

| Voltage | Nominal voltage: 12V, 6V, or 2V per cell |

| Capacity | Ranges from a few Ah to hundreds of Ah |

| Charging | Constant voltage charging with current limiting |

| Cycle Life | 300-500 cycles, depending on depth of discharge |

| Self-Discharge | Low self-discharge rate (3-5% per month) |

Charging Requirements for Sealed Lead Acid Batteries

To maximize the performance and lifespan of sealed lead acid batteries, it is essential to follow the proper charging requirements. SLA batteries require a constant voltage charging method with current limiting to prevent overcharging and damage to the battery.

Charging Stages

The charging process for SLA batteries typically consists of three stages:

-

Bulk Charging Stage: In this stage, the battery is charged with a constant current until it reaches approximately 70-80% of its capacity. The charging voltage is typically set to 14.4V-14.7V for a 12V battery.

-

Absorption Stage: Once the battery reaches the bulk charging voltage, the charging current gradually decreases while the voltage remains constant. This stage allows the battery to reach its full capacity without overcharging.

-

Float Charging Stage: After the absorption stage, the charging voltage is reduced to a lower level (typically 13.6V-13.8V for a 12V battery) to maintain the battery’s charge and compensate for self-discharge.

Charging Voltage and Current

The charging voltage and current for sealed lead acid batteries depend on the battery’s capacity and the desired charging time. A general rule of thumb is to set the charging current to 10-30% of the battery’s rated capacity (in Ah) for optimal charging.

For example, if you have a 12V, 100Ah SLA battery, the recommended charging current would be 10A-30A, and the charging voltage would be set to 14.4V-14.7V for the bulk and absorption stages, and 13.6V-13.8V for the float stage.

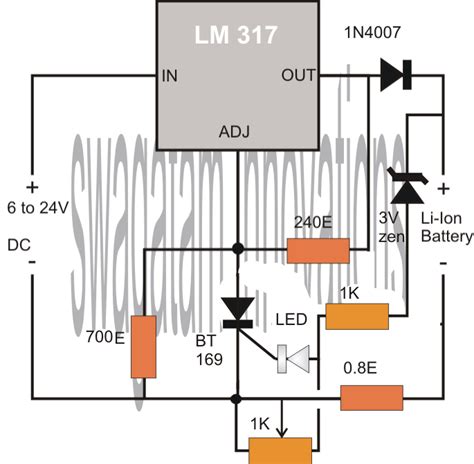

Sealed Lead Acid Battery Charging Circuit diagram

A typical sealed lead acid battery charging circuit consists of several key components, including a power supply, a Voltage Regulator, a current limiter, and a battery management system (BMS). The following diagram illustrates a basic SLA battery charging circuit:

[Insert circuit diagram image here]

Circuit Components

-

Power Supply: The power supply provides the necessary input voltage and current for charging the battery. It can be an AC-to-DC converter or a DC power source, depending on the application.

-

Voltage Regulator: The voltage regulator maintains a constant charging voltage throughout the charging process. It ensures that the battery is charged at the appropriate voltage levels for each charging stage (bulk, absorption, and float).

-

Current Limiter: The current limiter restricts the charging current to a safe level, preventing overcharging and damage to the battery. It can be implemented using a simple resistor or a more advanced current control circuit.

-

Battery Management System (BMS): The BMS monitors the battery’s voltage, current, and temperature during the charging process. It provides protection features such as overcharge protection, overdischarge protection, and temperature monitoring to ensure safe and efficient charging.

Charging Algorithm

The charging algorithm for sealed lead acid batteries typically follows these steps:

-

Initialize the charging process by setting the charging voltage to the bulk charging level (14.4V-14.7V for a 12V battery) and the current limit to the desired value (10-30% of the battery’s capacity).

-

Monitor the battery voltage and current during the bulk charging stage. Once the battery reaches the bulk charging voltage, transition to the absorption stage.

-

During the absorption stage, maintain the charging voltage at the bulk level while the current gradually decreases. Continue this stage until the battery is fully charged or the charging current drops below a predetermined threshold (typically 1-3% of the battery’s capacity).

-

After the absorption stage, switch to the float charging stage by reducing the charging voltage to the float level (13.6V-13.8V for a 12V battery). Maintain this voltage to keep the battery fully charged and compensate for self-discharge.

-

Continuously monitor the battery’s voltage, current, and temperature using the BMS. If any abnormal conditions are detected (e.g., overcharging, overheating), take appropriate actions such as reducing the charging current or disconnecting the battery.

Design Considerations for Sealed Lead Acid Battery Charging Circuits

When designing a sealed lead acid battery charging circuit, several key factors should be considered to ensure optimal performance, safety, and reliability:

-

Battery Capacity: Choose a charging circuit that can handle the battery’s capacity and provide the appropriate charging current and voltage levels.

-

Charging Time: Consider the desired charging time and select components that can deliver the necessary charging current within that timeframe.

-

Efficiency: Opt for high-efficiency components, such as switched-mode power supplies and low-dropout voltage regulators, to minimize power losses and heat generation during the charging process.

-

Protection Features: Incorporate protection features, such as overcharge protection, overdischarge protection, and temperature monitoring, to prevent damage to the battery and ensure safe operation.

-

Monitoring and Indication: Include monitoring and indication features, such as LED indicators or a display, to provide visual feedback on the charging status and any fault conditions.

-

Expandability: Design the charging circuit with expandability in mind, allowing for future upgrades or modifications to accommodate different battery capacities or charging requirements.

Implementing a Sealed Lead Acid Battery Charging Circuit

To implement a sealed lead acid battery charging circuit, follow these general steps:

-

Select the appropriate components based on the battery’s specifications and the desired charging characteristics.

-

Design the circuit schematic, including the power supply, voltage regulator, current limiter, and BMS.

-

Choose suitable component values, such as resistors and capacitors, to achieve the desired charging voltages and currents.

-

Assemble the circuit on a breadboard or PCB, ensuring proper connections and grounding.

-

Test the circuit with a sealed lead acid battery, monitoring the charging voltage, current, and temperature to verify proper operation.

-

Optimize the circuit as needed, fine-tuning the component values and protection settings to achieve optimal charging performance and safety.

-

Integrate the charging circuit into the final application, such as a backup power system or an electric vehicle, following the manufacturer’s guidelines and safety precautions.

Frequently Asked Questions (FAQ)

-

Q: Can I use a regular lead acid battery charger for sealed lead acid batteries?

A: While regular lead acid Battery Chargers may work with sealed lead acid batteries, it is recommended to use a charger specifically designed for SLA batteries to ensure optimal charging and prevent damage to the battery. -

Q: How long does it take to charge a sealed lead acid battery?

A: The charging time depends on the battery’s capacity and the charging current. As a general rule, it takes approximately 10-15 hours to fully charge an SLA battery using a charging current equal to 10% of its capacity (e.g., 10A for a 100Ah battery). -

Q: What happens if I overcharge a sealed lead acid battery?

A: Overcharging an SLA battery can lead to the formation of excessive gases, increased internal pressure, and damage to the battery’s plates and separators. This can result in reduced battery performance, shorter lifespan, and even safety hazards such as battery swelling or rupture. -

Q: How often should I charge my sealed lead acid battery?

A: It is recommended to charge SLA batteries when they are discharged to about 50% of their capacity or every 3-6 months if not in use. Avoid leaving SLA batteries in a discharged state for extended periods, as this can lead to sulfation and permanent capacity loss. -

Q: Can I use a solar panel to charge a sealed lead acid battery?

A: Yes, solar panels can be used to charge SLA batteries, but a proper charge controller must be used to regulate the charging voltage and current. The charge controller should be compatible with the solar panel’s output and the battery’s charging requirements to ensure safe and efficient charging.

Conclusion

A well-designed sealed lead acid battery charging circuit is essential for maintaining the performance and longevity of SLA batteries. By understanding the charging requirements, selecting the appropriate components, and implementing the necessary protection features, you can create a reliable and efficient charging system for your SLA battery-powered applications. Always follow the manufacturer’s guidelines and safety precautions when working with batteries and charging circuits.

Remember to regularly monitor your SLA battery’s health and charging status to ensure optimal performance and prevent potential issues. With proper care and maintenance, your sealed lead acid battery can provide reliable power for years to come.

Leave a Reply