What is Profiling V-cut?

Profiling V-cut, also known as V-grooving or V-scoring, is a technique used in the packaging and printing industry to create precise, clean folds in various materials, such as paper, cardboard, or plastic. This method involves cutting a V-shaped groove into the material, which allows for easier and more accurate folding. Profiling V-cut scoring is particularly useful for creating packages, boxes, and other items that require sharp, professional-looking folds.

How Profiling V-cut Works

The process of creating a V-cut involves using a specialized machine or tool that cuts a V-shaped groove into the material. The depth and angle of the cut can be adjusted depending on the thickness and type of material being used. The V-shaped groove removes some of the material’s fibers, which reduces the tension and allows for a cleaner, more precise fold.

Advantages of Profiling V-cut Scoring

- Clean, precise folds: V-cut scoring creates crisp, professional-looking folds that enhance the overall appearance of the final product.

- Reduced cracking and tearing: By removing some of the material’s fibers, V-cut scoring reduces the risk of cracking or tearing along the fold line.

- Versatility: Profiling V-cut can be used on a wide range of materials, including paper, cardboard, plastic, and even some thin metals.

- Increased efficiency: V-cut scoring allows for faster and more accurate folding, which can help streamline the production process and reduce waste.

Applications of Profiling V-cut Scoring

Packaging Industry

One of the most common applications of profiling V-cut scoring is in the packaging industry. V-cut scoring is used to create various types of packages, including:

- Boxes: V-cut scoring is ideal for creating clean, sharp folds in boxes of all sizes, from small product boxes to large shipping containers.

- Envelopes: V-cut scoring can be used to create professional-looking envelopes with crisp, precise folds.

- Packaging inserts: V-cut scoring is often used to create inserts, such as those used in product packaging to separate or protect items.

Printing Industry

Profiling V-cut scoring is also widely used in the printing industry for creating various printed materials, such as:

- Brochures and folders: V-cut scoring allows for the creation of clean, professional-looking folds in brochures and folders, enhancing their overall appearance and functionality.

- Greeting cards: V-cut scoring is often used to create crisp, precise folds in greeting cards, giving them a high-quality, professional look.

- Book covers: V-cut scoring can be used to create clean, sharp folds in book covers, enhancing their durability and visual appeal.

Other Applications

In addition to the packaging and printing industries, profiling V-cut scoring is used in various other applications, such as:

- Displays: V-cut scoring can be used to create displays for products, such as point-of-sale stands or promotional materials.

- Signs: V-cut scoring is sometimes used to create folds in signs or banners, allowing them to be easily stored or transported.

- Crafts: V-cut scoring can be used in various craft projects, such as creating custom boxes, cards, or decorations.

Types of Profiling V-cut Scoring

There are several types of profiling V-cut scoring, each with its own characteristics and applications:

| Type | Description | Applications |

|---|---|---|

| Standard V-cut | A simple V-shaped groove cut into the material at a fixed angle and depth | Suitable for most general folding applications |

| Adjustable V-cut | Allows for the adjustment of the angle and depth of the V-shaped groove | Ideal for materials of varying thicknesses or for creating custom folds |

| Multi-level V-cut | Involves cutting multiple V-shaped grooves at different depths | Used for creating more complex folds or for reinforcing the fold line |

| Perforated V-cut | Combines V-cut scoring with perforation, creating a tear-away strip along the fold line | Useful for creating easy-open packaging or for separating sections of a product |

Profiling V-cut Scoring Equipment

To create profiling V-cut scores, various types of equipment can be used, depending on the specific application and production volume:

Manual V-cut Scoring Tools

For small-scale or low-volume production, manual V-cut scoring tools can be used. These tools typically consist of a handle and a shaped blade that creates the V-shaped groove when pressed into the material. Manual V-cut scoring tools are relatively inexpensive and easy to use, but they may not be suitable for high-volume production or for materials that require precise, consistent scoring.

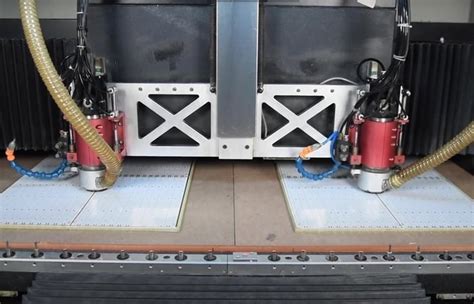

Automated V-cut Scoring Machines

For larger-scale production or for applications that require high precision, automated V-cut scoring machines are often used. These machines can create V-cut scores quickly and accurately, with minimal manual intervention. Some common types of automated V-cut scoring machines include:

- Rotary V-cut scoring machines: These machines use a rotating cutting wheel to create the V-shaped groove in the material. They are suitable for high-volume production and can handle a wide range of materials.

- Platen V-cut scoring machines: These machines use a flat cutting die to create the V-shaped groove. They are ideal for smaller production runs or for materials that require a more precise, consistent score.

- Laser V-cut scoring machines: These machines use a laser to create the V-shaped groove in the material. They offer high precision and can handle a wide range of materials, but they may be more expensive than other types of automated V-cut scoring machines.

Factors to Consider When Choosing Profiling V-cut Scoring

When selecting the appropriate profiling V-cut scoring method for a specific application, several factors should be considered:

- Material type and thickness: The type and thickness of the material being scored will influence the choice of V-cut scoring method. Some materials may require a specific type of V-cut scoring to achieve the desired result.

- Production volume: The volume of production will determine whether manual or automated V-cut scoring equipment is more suitable. High-volume production typically requires automated equipment for efficiency and consistency.

- Precision and consistency requirements: The level of precision and consistency required for the final product will influence the choice of V-cut scoring equipment. Applications that demand high precision may require more advanced automated equipment.

- Cost: The cost of V-cut scoring equipment and tooling should be considered in relation to the overall production budget. Manual tools may be more cost-effective for small-scale production, while automated equipment may be more cost-effective for high-volume production in the long run.

- Maintenance and durability: The maintenance requirements and durability of the V-cut scoring equipment should be considered, as this can impact the overall cost and efficiency of the production process.

Best Practices for Profiling V-cut Scoring

To ensure the best results when using profiling V-cut scoring, consider the following best practices:

- Choose the appropriate V-cut scoring method: Select the V-cut scoring method that best suits the material, production volume, and precision requirements of the application.

- Test and adjust settings: Before beginning full-scale production, test the V-cut scoring equipment on a sample of the material to ensure the desired results are achieved. Adjust the settings as necessary to optimize the quality of the V-cut score.

- Perform regular maintenance: Regular maintenance of the V-cut scoring equipment, such as cleaning and replacing worn parts, can help ensure consistent, high-quality results and extend the life of the equipment.

- Train operators: Ensure that operators are properly trained in the use of the V-cut scoring equipment and follow all safety guidelines to minimize the risk of accidents or damage to the equipment or materials.

- Monitor quality: Regularly monitor the quality of the V-cut scores produced to ensure consistency and identify any issues that may require adjustments to the equipment or process.

Frequently Asked Questions (FAQ)

-

What is the difference between profiling V-cut scoring and other types of scoring?

Profiling V-cut scoring creates a V-shaped groove in the material, which allows for cleaner, more precise folds than other types of scoring, such as crease or perforation scoring. V-cut scoring removes some of the material’s fibers, reducing the tension along the fold line and minimizing the risk of cracking or tearing. -

Can profiling V-cut scoring be used on any material?

Profiling V-cut scoring can be used on a wide range of materials, including paper, cardboard, plastic, and some thin metals. However, the specific type of V-cut scoring method and equipment used may vary depending on the material’s characteristics and thickness. -

Is profiling V-cut scoring suitable for all types of folding applications?

While profiling V-cut scoring is suitable for many folding applications, particularly those that require clean, precise folds, it may not be necessary or appropriate for all folding applications. Some simple folding applications may be achievable with other types of scoring, such as crease scoring, which may be more cost-effective. -

How does the depth of the V-cut score affect the folding process?

The depth of the V-cut score can affect the ease and accuracy of the folding process. A deeper V-cut score will remove more of the material’s fibers, making it easier to fold and reducing the risk of cracking or tearing. However, if the V-cut score is too deep, it may weaken the material and cause it to break along the fold line. -

Can profiling V-cut scoring be combined with other finishing techniques?

Yes, profiling V-cut scoring can be combined with other finishing techniques, such as printing, laminating, or die-cutting, to create more complex or visually appealing products. However, it is important to consider the compatibility of the various techniques and ensure that the V-cut scoring process does not interfere with or detract from the other finishing techniques.

In conclusion, profiling V-cut scoring is a versatile and effective method for creating clean, precise folds in a wide range of materials. By understanding the various types of V-cut scoring, equipment options, and best practices, businesses can optimize their folding processes and produce high-quality products that meet the needs of their customers. As with any production process, careful consideration of factors such as material type, production volume, and precision requirements, as well as regular maintenance and quality monitoring, can help ensure the best results and maximize the benefits of profiling V-cut scoring.

Leave a Reply