Understanding PCBs and Their Importance

What are PCBs?

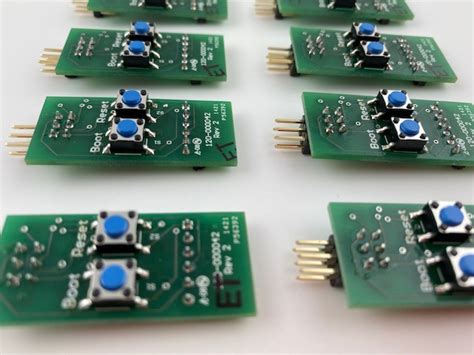

PCBs are thin boards made of insulating materials, such as fiberglass or composite epoxy, with conductive copper tracks printed on them. These boards provide mechanical support and electrical connections for various electronic components, including resistors, capacitors, and integrated circuits (ICs). PCBs enable the efficient assembly and functioning of electronic devices by eliminating the need for complex wiring.

The Role of PCBs in Modern Electronics

PCBs play a crucial role in the electronics industry, as they are used in a wide range of applications:

- Consumer electronics: Smartphones, tablets, laptops, televisions, and gaming consoles

- Automotive industry: In-vehicle infotainment systems, engine control units, and advanced driver assistance systems (ADAS)

- Industrial equipment: Automation systems, robotics, and process control devices

- Medical devices: Diagnostic equipment, monitoring systems, and wearable health devices

- Aerospace and defense: Avionics, radar systems, and satellite communication devices

The demand for PCBs has grown significantly in recent years due to the rapid advancement of technology and the increasing prevalence of electronic devices in our daily lives.

Causes of the PCB Shortage

Several factors have contributed to the current PCB shortage:

Increased Demand for Electronics

The COVID-19 pandemic has accelerated the adoption of digital technologies, leading to a surge in demand for electronic devices. Remote work, online learning, and virtual entertainment have become more common, driving up the need for laptops, tablets, and networking equipment. Additionally, the automotive industry’s shift towards electric vehicles (EVs) and the growing popularity of IoT devices have further increased the demand for PCBs.

Supply Chain Disruptions

The pandemic has also caused significant disruptions in global supply chains. Lockdowns and travel restrictions have affected the production and transportation of raw materials and components required for PCB manufacturing. The closure of factories and logistical challenges have led to delays in the delivery of PCBs to electronics manufacturers.

Limited Production Capacity

PCB manufacturers have been struggling to keep up with the growing demand due to limited production capacity. The complex and time-consuming nature of PCB fabrication, coupled with the need for specialized equipment and skilled labor, has made it difficult for manufacturers to quickly scale up production. Additionally, the consolidation of the PCB industry in recent years has reduced the number of suppliers, further constraining production capacity.

Raw Material Shortages

The PCB industry relies on various raw materials, such as copper, fiberglass, and resins. The increased demand for these materials from other industries, such as construction and renewable energy, has led to shortages and price fluctuations. The limited availability of raw materials has further exacerbated the PCB shortage.

Impact of the PCB Shortage

The PCB shortage has far-reaching consequences for the electronics industry and beyond:

Production Delays and Increased Costs

Electronics manufacturers are facing longer lead times for PCBs, which can range from several weeks to several months. These delays have forced companies to postpone product launches and limit production volumes. Additionally, the shortage has driven up the prices of PCBs, as suppliers struggle to meet the growing demand. The increased costs are often passed on to consumers, resulting in higher prices for electronic devices.

Supply Chain Disruptions

The PCB shortage has created a ripple effect throughout the electronics supply chain. Manufacturers are struggling to secure the necessary components, leading to production bottlenecks and delays in the delivery of finished products. This has led to increased competition for available PCBs, with some companies resorting to stockpiling or paying premiums to secure their supply.

Impact on Industries

The PCB shortage has affected various industries that rely on electronic components:

- Consumer electronics: The shortage has led to delays in the launch of new smartphones, laptops, and gaming consoles, as well as limited availability and higher prices for existing products.

- Automotive industry: The shortage has forced automakers to cut production and prioritize the allocation of available PCBs to high-margin vehicles. This has resulted in longer waiting times for new cars and increased prices for consumers.

- Medical devices: The shortage has affected the production of critical medical equipment, such as ventilators and patient monitoring systems, potentially impacting patient care.

- Industrial equipment: The shortage has delayed the deployment of automation systems and IoT devices, affecting the efficiency and competitiveness of industries such as manufacturing and logistics.

Economic Impact

The PCB shortage has broader economic implications, as the electronics industry is a significant contributor to global GDP and employment. The shortage has led to reduced revenue for electronics manufacturers, suppliers, and retailers, as well as job losses in affected industries. The longer the shortage persists, the greater the potential for economic slowdown and reduced consumer spending.

Strategies to Mitigate the PCB Shortage

Electronics manufacturers and PCB Suppliers are adopting various strategies to mitigate the impact of the shortage:

Diversifying Suppliers

Companies are looking to diversify their PCB supplier base to reduce their reliance on a single source. By working with multiple suppliers in different regions, manufacturers can minimize the risk of supply chain disruptions and ensure a more stable supply of PCBs.

Redesigning Products

Some manufacturers are redesigning their products to use fewer or more readily available components. By simplifying product designs or using alternative materials, companies can reduce their dependence on scarce PCBs and maintain production levels.

Investing in Capacity Expansion

PCB manufacturers are investing in capacity expansion to meet the growing demand. This includes adding new production lines, upgrading equipment, and hiring additional skilled labor. However, capacity expansion takes time and requires significant capital investment, making it a long-term solution.

Improving Supply Chain Visibility

Companies are investing in supply chain visibility tools to better track the movement of PCBs and other components. By having real-time information on inventory levels, production status, and delivery times, manufacturers can make informed decisions and quickly adapt to changing market conditions.

Government Intervention

Governments are also taking steps to address the PCB shortage. Some countries are offering financial incentives and tax breaks to encourage domestic PCB production and reduce reliance on foreign suppliers. Additionally, governments are working to improve trade relations and reduce tariffs on PCB imports to ease supply chain constraints.

Future Outlook and Lessons Learned

The PCB shortage is expected to persist throughout 2021 and potentially into 2022, as the demand for electronic devices continues to grow and supply chains remain disrupted. However, the long-term outlook for the PCB industry remains positive, as the increasing adoption of digital technologies and the growth of emerging markets drive demand for electronic components.

The current shortage has highlighted the importance of supply chain resilience and the need for a more diversified and flexible manufacturing ecosystem. Electronics manufacturers and PCB suppliers must work together to build stronger relationships, improve communication, and invest in capacity expansion and technology innovation.

Additionally, the shortage has underscored the need for greater collaboration between industry stakeholders and governments to address supply chain challenges and ensure the long-term competitiveness of the electronics industry.

Frequently Asked Questions (FAQ)

1. What is a PCB, and why is it important?

A PCB, or printed circuit board, is a thin board made of insulating materials with conductive copper tracks printed on it. PCBs provide mechanical support and electrical connections for various electronic components, enabling the efficient assembly and functioning of electronic devices. PCBs are essential in almost all electronic devices, from smartphones and laptops to automotive systems and medical equipment.

2. What are the main causes of the current PCB shortage?

The main causes of the current PCB shortage include increased demand for electronics due to the COVID-19 pandemic, supply chain disruptions, limited production capacity, and raw material shortages. The surge in demand for electronic devices, coupled with logistical challenges and constraints in the PCB manufacturing process, has led to a global shortage of PCBs.

3. Which industries are most affected by the PCB shortage?

The PCB shortage has affected various industries that rely on electronic components, including consumer electronics, automotive, medical devices, and industrial equipment. The shortage has led to production delays, increased costs, and supply chain disruptions in these industries, impacting businesses and consumers worldwide.

4. How are electronics manufacturers and PCB suppliers mitigating the impact of the shortage?

Electronics manufacturers and PCB suppliers are adopting strategies such as diversifying suppliers, redesigning products, investing in capacity expansion, and improving supply chain visibility to mitigate the impact of the shortage. These measures aim to reduce reliance on scarce components, ensure a more stable supply of PCBs, and adapt to changing market conditions.

5. What is the future outlook for the PCB industry, and what lessons can be learned from the current shortage?

The PCB shortage is expected to persist throughout 2021 and potentially into 2022, but the long-term outlook for the industry remains positive due to the increasing adoption of digital technologies and the growth of emerging markets. The current shortage has highlighted the importance of supply chain resilience, diversification, and collaboration between industry stakeholders and governments to address supply chain challenges and ensure the long-term competitiveness of the electronics industry.

| Industry | Impact of PCB Shortage |

|---|---|

| Consumer Electronics | Delays in product launches, limited availability, and higher prices for smartphones, laptops, etc. |

| Automotive | Cut production, prioritized allocation of PCBs to high-margin vehicles, longer waiting times for new cars, and increased prices. |

| Medical Devices | Affected production of critical equipment like ventilators and patient monitoring systems, potentially impacting patient care. |

| Industrial Equipment | Delayed deployment of automation systems and IoT devices, affecting efficiency and competitiveness. |

The PCB shortage has far-reaching consequences for the electronics industry and the global economy. As the demand for electronic devices continues to grow, it is crucial for industry stakeholders to work together to build a more resilient and adaptive supply chain. By investing in capacity expansion, fostering collaboration, and embracing innovation, the PCB industry can overcome the current challenges and position itself for long-term success in the increasingly digital world.

Leave a Reply