What are PCB Manufacturers?

PCB manufacturers are companies that specialize in the production of printed circuit boards (PCBs). These boards are essential components in modern electronic devices, providing a platform for electrical components to be mounted and connected. PCB manufacturers play a crucial role in the electronics industry, serving a wide range of sectors, including consumer electronics, automotive, aerospace, medical devices, and telecommunications.

The Role of PCB Manufacturers

PCB manufacturers are responsible for the following tasks:

- Designing PCBs based on customer specifications

- Sourcing raw materials, such as copper-clad laminates and solder masks

- Fabricating PCBs using various processes, including etching, drilling, and plating

- Conducting quality control tests to ensure the manufactured PCBs meet the required standards

- Packaging and shipping the finished PCBs to customers

The Advantages of Online PCB Manufacturers

In recent years, online PCB manufacturers have gained popularity due to their numerous advantages over traditional brick-and-mortar manufacturers. Some of these advantages include:

1. Convenience

Online PCB manufacturers offer a convenient way for customers to place orders, track progress, and receive finished products without the need for physical visits or extensive communication. Customers can easily upload their PCB designs, specify their requirements, and receive instant quotes.

2. Competitive Pricing

The online platform allows PCB manufacturers to streamline their operations, reduce overhead costs, and offer competitive pricing to their customers. This is particularly beneficial for small and medium-sized businesses that may have limited budgets for their electronic projects.

3. Faster Turnaround Times

Online PCB manufacturers often have optimized production processes and efficient supply chains, enabling them to deliver finished products faster than traditional manufacturers. This is crucial for businesses that need to bring their products to market quickly to stay competitive.

4. Wide Range of Services

Many online PCB manufacturers offer a comprehensive range of services, including PCB design, prototyping, assembly, and testing. This allows customers to find a one-stop solution for their PCB needs, saving time and effort in coordinating with multiple vendors.

Choosing the Right Online PCB Manufacturer

When selecting an online PCB manufacturer, it is essential to consider several factors to ensure a successful partnership. Some key considerations include:

1. Experience and Expertise

Look for a manufacturer with a proven track record in producing high-quality PCBs for various industries. Experienced manufacturers are more likely to have the knowledge and skills to handle complex projects and provide valuable guidance throughout the production process.

2. Manufacturing Capabilities

Ensure that the chosen manufacturer has the necessary equipment and facilities to produce PCBs that meet your specific requirements. This includes the ability to handle different PCB types (e.g., single-sided, double-sided, or multi-layered), materials, and surface finishes.

3. Quality Control Measures

A reliable online PCB manufacturer should have stringent quality control measures in place to ensure that the manufactured PCBs meet the required standards. This may include automated optical inspection (AOI), X-ray inspection, and electrical testing.

4. Customer Support

Choose a manufacturer that offers excellent customer support, with responsive communication channels and a dedicated team to address any concerns or questions you may have throughout the production process.

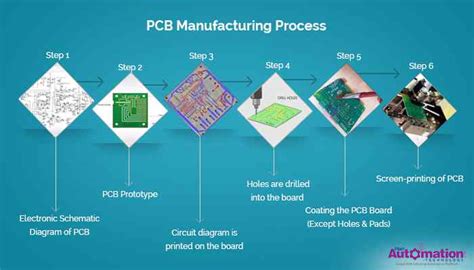

The PCB Manufacturing Process

The PCB manufacturing process typically involves several stages, each requiring specialized equipment and expertise. The main steps in the process include:

-

PCB Design: The customer provides the PCB design files, which are reviewed and optimized by the manufacturer’s engineering team.

-

Material Selection: The appropriate copper-clad laminate and other raw materials are selected based on the PCB’s specifications and intended application.

-

Etching: The copper-clad laminate is coated with a photoresist, exposed to UV light through a photomask, and developed to create the desired circuit pattern. The excess copper is then etched away using a chemical solution.

-

Drilling: Holes are drilled into the PCB to accommodate through-hole components and provide electrical connections between layers.

-

Plating: The drilled holes are plated with copper to ensure proper electrical conductivity.

-

Solder Mask Application: A protective solder mask is applied to the PCB to prevent short circuits and improve the board’s durability.

-

Silkscreen Printing: Text, logos, and other markings are printed onto the PCB using a silkscreen process.

-

Surface Finishing: The exposed copper areas are coated with a surface finish, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative), to protect the copper from oxidation and enhance solderability.

-

Electrical Testing: The manufactured PCBs undergo various electrical tests to ensure they function as intended and meet the specified requirements.

-

Packaging and Shipping: The finished PCBs are packaged and shipped to the customer.

PCB Materials and Their Properties

PCBs can be manufactured using various materials, each with its own unique properties and advantages. The most common PCB materials include:

| Material | Properties | Applications |

|---|---|---|

| FR-4 | – Good electrical insulation – High mechanical strength – Flame retardant |

– General-purpose electronics – Consumer devices – Industrial applications |

| Polyimide | – High heat resistance – Excellent dimensional stability – Lightweight |

– Aerospace – Military – High-temperature applications |

| Aluminum | – Excellent thermal conductivity – Lightweight – Rigid |

– Power electronics – LED lighting – Automotive applications |

| Flexible PCBs | – Thin and flexible – Lightweight – Conformable |

– Wearable devices – Medical implants – Aerospace applications |

PCB Surface Finishes

Surface finishes are applied to the exposed copper areas of a PCB to protect the copper from oxidation, enhance solderability, and improve the board’s shelf life. Some common surface finishes include:

| Surface Finish | Advantages | Disadvantages |

|---|---|---|

| HASL (Hot Air Solder Leveling) | – Low cost – Good solderability – Excellent shelf life |

– Uneven surface – Not suitable for fine-pitch components |

| ENIG (Electroless Nickel Immersion Gold) | – Flat surface – Excellent solderability – Suitable for fine-pitch components |

– Higher cost than HASL – Possible nickel corrosion |

| OSP (Organic Solderability Preservative) | – Low cost – Flat surface – Suitable for fine-pitch components |

– Limited shelf life – Possible copper oxidation |

Frequently Asked Questions (FAQ)

- What is the minimum order quantity (MOQ) for PCBs from online manufacturers?

-

The MOQ varies depending on the manufacturer, but many online PCB manufacturers offer low MOQs, sometimes as low as 5 or 10 pieces, to accommodate small-scale projects and prototyping needs.

-

How long does it take to receive PCBs from an online manufacturer?

-

The turnaround time depends on the complexity of the PCB, the selected manufacturing options, and the manufacturer’s workload. However, many online PCB manufacturers offer expedited services, with turnaround times ranging from 24 hours to 5 business days.

-

Can online PCB manufacturers handle both prototype and mass production orders?

-

Yes, most online PCB manufacturers are equipped to handle both prototype and mass production orders. They often offer different pricing tiers and manufacturing options to cater to the specific needs of each type of order.

-

What file formats do online PCB manufacturers accept for PCB designs?

-

Online PCB manufacturers typically accept industry-standard file formats, such as Gerber files (RS-274X), ODB++, and IPC-2581. Some manufacturers also accept PCB design files from popular CAD software, such as Altium Designer, Eagle, and KiCad.

-

Do online PCB manufacturers offer assembly services?

- Many online PCB manufacturers offer Turnkey PCB assembly services, which include sourcing components, assembling the PCBs, and testing the assembled boards. This allows customers to receive a complete, ready-to-use product without the need to coordinate with multiple vendors.

Conclusion

Online PCB manufacturers have revolutionized the way businesses and individuals source printed circuit boards for their electronic projects. With their convenience, competitive pricing, faster turnaround times, and wide range of services, online PCB manufacturers have become an essential part of the global electronics industry.

When choosing an online PCB manufacturer, it is crucial to consider factors such as experience, manufacturing capabilities, quality control measures, and customer support to ensure a successful partnership. By understanding the PCB manufacturing process, materials, and surface finishes, customers can make informed decisions and select the best options for their specific needs.

As technology continues to advance and the demand for electronic devices grows, online PCB manufacturers will play an increasingly important role in enabling innovation and supporting the development of cutting-edge products across various industries.

Leave a Reply