Introduction to PCB Manufacturing

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, from smartphones and computers to medical equipment and aerospace technology. PCB manufacturing is a complex process that involves designing, fabricating, and assembling electronic circuits on a non-conductive substrate. As the global demand for electronic devices continues to grow, the PCB manufacturing industry has become increasingly competitive, with China and the United States being two of the largest players in the market.

In this article, we will explore the differences between PCB manufacturing in China and the United States, including factors such as cost, quality, lead times, and technological capabilities. We will also discuss the advantages and disadvantages of outsourcing PCB manufacturing to China and the recent trends in the industry.

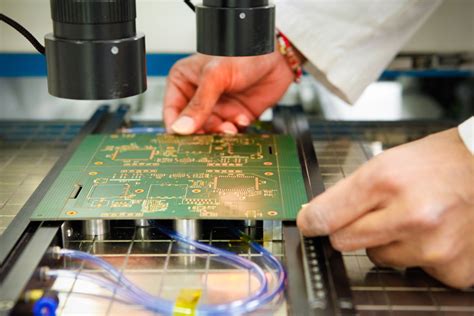

The PCB Manufacturing Process

Before diving into the comparison between China and the US, let’s briefly overview the PCB manufacturing process. PCB manufacturing typically involves the following steps:

-

Design: The PCB design is created using specialized software, such as Altium Designer or Eagle CAD. The design includes the circuit layout, component placement, and routing of the electrical connections.

-

Fabrication: The PCB design is transferred to a copper-clad laminate board through a process called photolithography. The board is then etched to remove the unwanted copper, leaving only the desired circuit pattern.

-

Drilling: Holes are drilled into the board to accommodate through-hole components and to create vias for electrical connections between layers in multi-layer PCBs.

-

Plating: The holes are plated with a conductive material, typically copper, to ensure electrical continuity.

-

Solder Mask Application: A protective solder mask is applied to the board to prevent short circuits and to protect the copper traces from oxidation.

-

Silkscreen Printing: The component labels, logos, and other markings are printed onto the board using a silkscreen process.

-

Surface Finish: A surface finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the exposed copper to prevent oxidation and to improve solderability.

-

Assembly: The electronic components are placed and soldered onto the board, either through manual assembly or automated pick-and-place machines.

-

Testing and Inspection: The assembled PCBs undergo various tests and inspections to ensure functionality, quality, and reliability.

PCB Manufacturing in China

China has emerged as a global leader in PCB manufacturing over the past few decades, thanks to its low labor costs, extensive supply chain, and government support for the electronics industry. According to a report by Global Market Insights, China accounted for over 50% of the global PCB market share in 2020, with a projected growth rate of 4.5% from 2021 to 2027.

Advantages of PCB Manufacturing in China

-

Lower Costs: One of the primary reasons companies choose to manufacture PCBs in China is the significantly lower cost compared to the United States. This is largely due to the lower labor costs and the economies of scale achieved by Chinese PCB manufacturers.

-

Extensive Supply Chain: China has a well-established supply chain for PCB manufacturing, with a wide range of suppliers for raw materials, components, and equipment. This allows for faster and more efficient production, as well as greater flexibility in sourcing materials.

-

Rapid Prototyping: Many Chinese PCB manufacturers offer rapid prototyping services, allowing companies to quickly produce small batches of PCBs for testing and validation before committing to large-scale production. This can significantly reduce development times and costs.

-

High-Volume Production: Chinese PCB manufacturers are well-equipped to handle high-volume production, with large factories and advanced automation capabilities. This allows them to produce PCBs at a much larger scale than most US manufacturers.

Disadvantages of PCB Manufacturing in China

-

Quality Concerns: While many Chinese PCB manufacturers produce high-quality boards, there have been instances of quality control issues, particularly among smaller or less reputable suppliers. This can lead to higher defect rates and reduced reliability.

-

Intellectual Property Risks: Outsourcing PCB manufacturing to China can potentially expose companies to intellectual property (IP) risks, as some Chinese manufacturers have been known to copy or reverse-engineer designs. Protecting IP can be challenging in China, and companies must take steps to safeguard their sensitive information.

-

Language and Communication Barriers: Working with Chinese PCB manufacturers can sometimes be challenging due to language and communication barriers. Misunderstandings can lead to delays, errors, and increased costs.

-

Longer Lead Times: While Chinese PCB manufacturers can often produce boards more quickly than their US counterparts, the longer shipping times from China to the US can offset this advantage. This can be particularly problematic for time-sensitive projects or those requiring frequent design iterations.

PCB Manufacturing in the United States

The United States has a long history of PCB manufacturing, with a strong focus on high-end, specialized applications such as military, aerospace, and medical devices. While the US may not have the same scale and cost advantages as China, it does offer several unique benefits for companies looking to manufacture PCBs.

Advantages of PCB Manufacturing in the United States

-

Higher Quality Standards: US PCB manufacturers are known for their strict adherence to quality standards and rigorous testing procedures. This ensures that the PCBs produced are of consistently high quality and reliability, which is particularly important for critical applications.

-

Advanced Technology: Many US PCB manufacturers specialize in advanced technologies, such as high-density interconnect (HDI) PCBs, flexible PCBs, and RF/microwave PCBs. These capabilities allow for the production of highly complex and sophisticated boards that may not be available from Chinese manufacturers.

-

Intellectual Property Protection: The United States has strong intellectual property laws and enforcement, which can provide greater protection for companies’ sensitive designs and information. This can be particularly important for industries such as defense, aerospace, and medical devices.

-

Proximity and Communication: For US-based companies, working with a local PCB manufacturer can offer significant advantages in terms of proximity, communication, and collaboration. Face-to-face meetings, shorter shipping times, and a common language and culture can streamline the development process and reduce the risk of errors.

Disadvantages of PCB Manufacturing in the United States

-

Higher Costs: PCB manufacturing in the United States is generally more expensive than in China, due to higher labor costs, stricter regulations, and more expensive raw materials. This can make it challenging for US manufacturers to compete on price, particularly for high-volume, cost-sensitive applications.

-

Limited Capacity: While the US has many high-quality PCB manufacturers, they often have limited capacity compared to their Chinese counterparts. This can make it difficult for US manufacturers to handle very large orders or to scale up production quickly.

-

Longer Lead Times: Due to the smaller scale of US PCB manufacturing and the higher demand for specialized applications, lead times for PCBs produced in the US can sometimes be longer than those produced in China. This can be a challenge for companies with tight deadlines or rapidly changing requirements.

Comparing PCB Manufacturing Costs: China vs. US

One of the most significant factors in deciding between PCB manufacturing in China or the US is cost. The table below provides a general comparison of the costs associated with PCB manufacturing in each country:

| Cost Factor | China | United States |

|---|---|---|

| Labor | Low ($2-$5/hour) | High ($15-$30/hour) |

| Materials | Low (abundant supply chain) | Moderate to High (more expensive) |

| Equipment | Low to Moderate (government subsidies) | High (advanced technology) |

| Shipping | Moderate to High (long distance) | Low to Moderate (domestic) |

| Duties and Tariffs | Moderate to High (import duties) | Low (domestic production) |

| Quality Control | Moderate (varies by manufacturer) | High (strict standards) |

| Intellectual Property | High Risk (limited protection) | Low Risk (strong legal framework) |

It’s important to note that these are general comparisons and that actual costs can vary significantly depending on the specific manufacturer, the complexity of the PCB design, and the volume of the order.

Recent Trends and Future Outlook

The PCB manufacturing industry is constantly evolving, driven by advancements in technology, changes in global trade policies, and shifts in consumer demand. Some of the recent trends and future outlook for PCB manufacturing in China and the US include:

-

Increasing Automation: Both Chinese and US PCB manufacturers are investing in advanced automation technologies to improve efficiency, reduce costs, and enhance quality control. This includes the use of robotics, artificial intelligence (AI), and machine learning in the manufacturing process.

-

Shifting Supply Chains: The ongoing trade tensions between the US and China, as well as the disruptions caused by the COVID-19 pandemic, have led some companies to diversify their supply chains and consider alternative manufacturing locations. This could lead to a gradual shift away from China and towards other countries in Asia, such as Vietnam, Thailand, and India.

-

Focus on High-End Applications: US PCB manufacturers are likely to continue focusing on high-end, specialized applications, such as 5G technology, autonomous vehicles, and advanced medical devices. These areas require advanced technological capabilities and strict quality control, which play to the strengths of US manufacturers.

-

Domestic Production Incentives: The US government has recently introduced initiatives to encourage domestic production of critical components, including PCBs. For example, the Department of Defense has launched the “Trusted Foundry” program, which provides incentives for US-based manufacturers to produce PCBs for military and aerospace applications.

FAQ

-

Q: How do I choose between PCB manufacturing in China and the US?

A: The decision ultimately depends on your specific requirements, such as cost, quality, lead time, and intellectual property protection. Consider the advantages and disadvantages of each location and evaluate which factors are most critical for your project. -

Q: Are Chinese PCB manufacturers always cheaper than US manufacturers?

A: While Chinese PCB manufacturers are generally cheaper than their US counterparts, this is not always the case. Some US manufacturers may be competitive on price for smaller orders or specialized applications. It’s essential to obtain quotes from multiple manufacturers in both countries to compare costs. -

Q: How can I ensure the quality of PCBs manufactured in China?

A: To ensure quality, work with reputable manufacturers who have a proven track record and strong quality control processes. Consider conducting factory audits, requesting product samples, and implementing rigorous testing and inspection procedures. -

Q: What are the risks of intellectual property theft when manufacturing PCBs in China?

A: Intellectual property theft is a legitimate concern when outsourcing PCB manufacturing to China. To mitigate this risk, consider working with trusted manufacturers, implementing non-disclosure agreements (NDAs), and taking steps to protect your sensitive designs and information. -

Q: Are there any benefits to manufacturing PCBs in the US for non-US companies?

A: Manufacturing PCBs in the US can offer benefits such as access to advanced technology, strict quality control, and strong intellectual property protection. Non-US companies may choose to manufacture in the US if they are targeting the US market or if they require specialized capabilities not readily available in their home countries.

Conclusion

PCB manufacturing is a critical component of the global electronics industry, and the decision to manufacture in China or the United States depends on a variety of factors, including cost, quality, lead time, and technological capabilities. While China offers significant cost advantages and a well-established supply chain, the United States is known for its high-quality standards, advanced technology, and strong intellectual property protection.

As the PCB manufacturing industry continues to evolve, companies must carefully consider their specific requirements and evaluate the trade-offs between cost, quality, and other factors. By understanding the advantages and disadvantages of PCB manufacturing in China and the US, companies can make informed decisions that balance their short-term needs with their long-term strategic goals.

Ultimately, the choice between PCB manufacturing in China and the US is not a one-size-fits-all decision, and companies must carefully assess their unique circumstances to determine the best approach for their projects.

Leave a Reply