What are PCB Batteries?

PCB batteries are a type of battery that integrates the battery cells and protection circuitry onto a single printed circuit board. This compact design allows for a more efficient use of space and enables the battery to be easily incorporated into various electronic devices. The protection circuit serves to monitor and control the battery’s charging and discharging processes, ensuring safe and optimal performance.

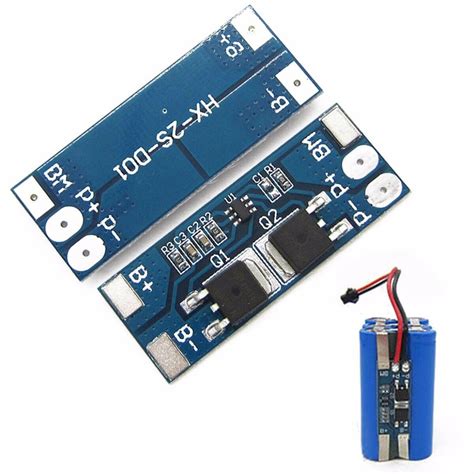

Key Components of PCB Batteries

- Battery Cells: PCB batteries typically use lithium-ion or lithium-polymer cells due to their high energy density and lightweight nature.

- Protection IC: The protection integrated circuit (IC) is the brain of the PCB battery, monitoring and controlling the charging and discharging processes.

- MOSFET Switches: Metal-oxide-semiconductor field-effect transistor (MOSFET) switches are used to control the flow of current in and out of the battery.

- Passive Components: Resistors, capacitors, and other passive components are used to support the protection circuitry and ensure stable operation.

Benefits of PCB Batteries

Space Savings and Compact Design

One of the primary advantages of PCB batteries is their compact size. By integrating the battery cells and protection circuitry onto a single PCB, designers can save valuable space within electronic devices. This is particularly important in portable and wearable devices, where every millimeter counts. The compact design also allows for more flexibility in device form factors and enables the creation of thinner and lighter products.

Enhanced Safety Features

PCB batteries incorporate advanced safety features through their integrated protection circuits. These circuits monitor the battery’s voltage, current, and temperature to prevent overcharging, over-discharging, and short-circuit conditions. In the event of any abnormalities, the protection circuit can quickly disconnect the battery from the device, preventing potential damage or safety hazards. This built-in protection enhances the overall safety of the device and reduces the risk of battery-related incidents.

Improved Performance and Reliability

The close integration of the battery cells and protection circuitry in PCB batteries leads to improved performance and reliability. By eliminating the need for external wiring and connectors, PCB batteries reduce resistance and minimize power losses. This results in more efficient power delivery and longer battery life. Additionally, the compact design and reduced number of components contribute to increased reliability, as there are fewer potential points of failure compared to traditional battery designs.

Simplified Manufacturing and Assembly

PCB batteries simplify the manufacturing and assembly process for electronic devices. With the battery cells and protection circuitry integrated onto a single PCB, the battery can be easily placed and soldered onto the main device PCB. This streamlines the assembly process, reduces the number of components to manage, and minimizes the risk of assembly errors. The simplified manufacturing process can lead to cost savings and faster production times.

Applications of PCB Batteries

Wearable Devices

PCB batteries are widely used in wearable devices, such as smartwatches, fitness trackers, and wireless earbuds. The compact size and lightweight nature of PCB batteries make them ideal for these applications, where space is limited and comfort is a priority. The integrated protection circuitry ensures the safety and reliability of the battery, even under the demanding conditions of wearable use.

Internet of Things (IoT) Devices

The Internet of Things (IoT) has revolutionized the way we interact with everyday objects, and PCB batteries play a crucial role in powering these connected devices. From smart home sensors to industrial monitoring systems, PCB batteries provide a reliable and space-efficient power solution. The compact design allows for the integration of batteries into small and distributed IoT devices, enabling them to operate wirelessly and autonomously.

Medical Devices

PCB batteries find applications in various medical devices, such as portable patient monitors, wearable health sensors, and implantable devices. The enhanced safety features of PCB batteries are particularly important in medical applications, where reliability and patient safety are paramount. The compact size of PCB batteries also enables the development of smaller and less invasive medical devices, improving patient comfort and mobility.

Portable Electronics

PCB batteries are widely used in portable electronic devices, such as smartphones, tablets, and portable gaming consoles. The space-saving design allows for thinner and lighter devices, while the integrated protection circuitry ensures safe and reliable battery performance. PCB batteries also enable faster charging and longer battery life, enhancing the user experience of portable electronics.

PCB Battery Technologies

Lithium-Ion PCB Batteries

Lithium-ion (Li-ion) PCB batteries are the most common type of PCB battery due to their high energy density, long cycle life, and low self-discharge rate. Li-ion PCB batteries offer a high voltage per cell (typically 3.6V) and can be recharged hundreds of times. The protection circuitry in Li-ion PCB batteries is crucial to prevent overcharging, over-discharging, and short-circuit conditions, ensuring safe operation.

Lithium-Polymer PCB Batteries

Lithium-polymer (LiPo) PCB batteries are a variation of Li-ion batteries that use a polymer electrolyte instead of a liquid electrolyte. LiPo PCB batteries offer several advantages, including a thinner profile, flexible form factor, and improved safety. The polymer electrolyte is less prone to leakage and can be shaped to fit various device designs. LiPo PCB batteries are commonly used in wearable devices and applications where a thin and flexible battery is required.

Solid-State PCB Batteries

Solid-state PCB batteries are an emerging technology that uses solid electrolytes instead of liquid or polymer electrolytes. Solid-state PCB batteries offer several potential advantages, including higher energy density, improved safety, and longer cycle life. The solid electrolyte is non-flammable and eliminates the risk of leakage, making solid-state PCB batteries an attractive option for applications where safety is critical. However, solid-state PCB batteries are still in the research and development phase and are not yet widely commercially available.

Frequently Asked Questions (FAQ)

-

What is the difference between PCB batteries and traditional batteries?

PCB batteries integrate the battery cells and protection circuitry onto a single printed circuit board, while traditional batteries have separate components. PCB batteries offer a more compact and space-saving design, enhanced safety features, and improved performance compared to traditional batteries. -

Can PCB batteries be recharged?

Yes, most PCB batteries, particularly those based on lithium-ion and lithium-polymer technologies, are rechargeable. The integrated protection circuitry in PCB batteries ensures safe and efficient charging and discharging cycles. -

What are the safety features of PCB batteries?

PCB batteries incorporate protection circuits that monitor the battery’s voltage, current, and temperature. These circuits prevent overcharging, over-discharging, and short-circuit conditions, enhancing the overall safety of the battery and the device it powers. In the event of any abnormalities, the protection circuit can quickly disconnect the battery to prevent potential damage or safety hazards. -

What are the applications of PCB batteries?

PCB batteries find applications in a wide range of electronic devices, including wearable devices, Internet of Things (IoT) devices, medical devices, and portable electronics. The compact size, enhanced safety features, and improved performance of PCB batteries make them suitable for applications where space is limited, and reliability is crucial. -

Are PCB batteries more expensive than traditional batteries?

The cost of PCB batteries compared to traditional batteries can vary depending on factors such as battery capacity, protection features, and manufacturing volume. While the initial cost of PCB batteries may be higher due to the integrated protection circuitry and compact design, the overall cost savings in terms of space, simplified manufacturing, and improved reliability can make PCB batteries a cost-effective solution in the long run.

Conclusion

PCB batteries represent a significant advancement in battery technology, offering a compact, safe, and efficient power solution for various electronic devices. By integrating battery cells and protection circuitry onto a single printed circuit board, PCB batteries enable space savings, enhanced safety features, improved performance, and simplified manufacturing. From wearable devices to IoT sensors and medical applications, PCB batteries are revolutionizing the way we power our electronic devices.

As technology continues to advance, we can expect further developments in PCB battery technologies, such as higher energy densities, faster charging capabilities, and even more compact designs. The potential of solid-state PCB batteries also holds promise for future applications where safety and performance are paramount.

In conclusion, PCB batteries are a vital component in the world of electronics, providing a reliable, safe, and space-efficient power solution. As we continue to push the boundaries of what is possible with electronic devices, PCB batteries will undoubtedly play a crucial role in powering the innovations of tomorrow.

Leave a Reply