What is NRE Cost?

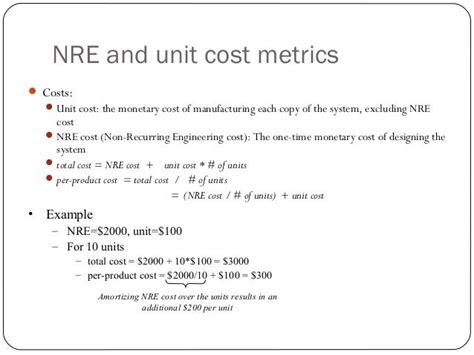

NRE cost, or Non-Recurring Engineering cost, refers to the one-time expenses incurred during the design and development phase of a product or project. These costs are typically associated with creating a new product or making significant changes to an existing one. NRE costs can include expenses related to research, design, prototyping, testing, and tooling.

Unlike recurring costs, which are ongoing expenses such as materials, labor, and overhead, NRE costs are incurred only once during the project’s lifecycle. However, these costs can be significant and can greatly impact the overall budget and timeline of a project.

Why is NRE Cost Important?

Understanding and managing NRE costs is crucial for several reasons:

-

Budget Planning: Accurately estimating NRE costs allows project managers to create a realistic budget and avoid unexpected expenses that can derail the project.

-

Resource Allocation: By identifying the various components of NRE costs, project managers can allocate resources more effectively, ensuring that each aspect of the project receives the necessary attention and funding.

-

Return on Investment (ROI): Evaluating NRE costs helps determine the potential ROI of a project. If the expected returns do not justify the initial investment, it may be necessary to reevaluate the project’s scope or explore alternative solutions.

-

Pricing Strategy: NRE costs play a role in determining the final price of a product. By understanding these costs, companies can develop a pricing strategy that ensures profitability while remaining competitive in the market.

Components of NRE Cost

NRE costs can be broken down into several key components:

Research and Development (R&D)

R&D expenses include the costs associated with researching market trends, customer needs, and competitive landscapes. This phase also involves conceptualizing and designing the product, which may require the expertise of engineers, designers, and other specialists.

Prototyping

Creating prototypes is an essential step in the product development process. Prototyping expenses can include materials, labor, and equipment costs. Multiple iterations may be necessary to refine the design and functionality of the product.

Testing and Validation

Before a product can be released to the market, it must undergo rigorous testing to ensure it meets quality standards and regulatory requirements. Testing expenses can include the cost of specialized equipment, facilities, and personnel.

Tooling and Equipment

Depending on the nature of the product, custom tooling and equipment may be required for manufacturing. These expenses can be significant, especially for complex or high-precision products.

Certification and Compliance

Many products must adhere to industry standards and regulations. Obtaining necessary certifications and ensuring compliance can add to the overall NRE costs.

Strategies for Managing NRE Costs

Effective management of NRE costs is essential for the success of any project. Here are some strategies to help keep these costs under control:

-

Thorough Planning: Invest time in creating a detailed project plan that identifies all potential NRE costs. This will help avoid surprises and ensure that the budget is allocated appropriately.

-

Design for Manufacturing (DFM): Incorporate DFM principles early in the design process to minimize the need for costly redesigns and tooling changes later on.

-

Leverage Existing Resources: Where possible, utilize existing designs, components, and tooling to reduce NRE costs. This can also help expedite the development process.

-

Collaborate with Suppliers: Work closely with suppliers to identify cost-saving opportunities and ensure that components meet the required specifications.

-

Continuous Improvement: Regularly review and analyze NRE costs to identify areas for improvement. Implement lessons learned from previous projects to optimize future development efforts.

NRE Cost Examples

To better understand NRE costs, let’s consider a few examples:

Example 1: Custom Electronic Device

| Component | Cost |

|---|---|

| Research and Development | $50,000 |

| Prototyping | $25,000 |

| Testing and Validation | $15,000 |

| Tooling and Equipment | $100,000 |

| Certification and Compliance | $10,000 |

| Total NRE Cost | $200,000 |

In this example, the most significant NRE cost is associated with tooling and equipment, which is common for electronic devices that require custom manufacturing processes.

Example 2: Software Development Project

| Component | Cost |

|---|---|

| Research and Development | $75,000 |

| Prototyping | $20,000 |

| Testing and Validation | $30,000 |

| Total NRE Cost | $125,000 |

For a software development project, the majority of NRE costs are typically related to research, development, and testing. Tooling and equipment costs are generally lower than in hardware-based projects.

FAQ

-

Q: Are NRE costs refundable?

A: No, NRE costs are non-refundable, as they represent the investment made in the design and development of a product. -

Q: How can I minimize NRE costs?

A: To minimize NRE costs, consider leveraging existing resources, collaborating with suppliers, and implementing design for manufacturing principles early in the development process. -

Q: Are NRE costs included in the unit price of a product?

A: NRE costs are not typically included in the unit price of a product. Instead, they are treated as a separate, one-time expense that is incurred during the development phase. -

Q: Can NRE costs be spread out over multiple projects?

A: In some cases, NRE costs can be spread out over multiple projects if the developed components or technologies can be reused in other applications. -

Q: How do I accurately estimate NRE costs?

A: To accurately estimate NRE costs, create a detailed project plan that identifies all potential expenses, and work closely with your team and suppliers to gather accurate cost information. It’s also helpful to review data from similar past projects.

Conclusion

NRE costs are a critical consideration in any product development project. By understanding the components of NRE costs and implementing effective management strategies, project managers can ensure that their projects remain on budget and on schedule. Thorough planning, collaboration with suppliers, and continuous improvement are key to minimizing NRE costs and maximizing the chances of project success. By carefully evaluating NRE costs and their potential impact on ROI, companies can make informed decisions about which projects to pursue and how to allocate their resources effectively.

Leave a Reply