What is Battery Internal Resistance?

Battery internal resistance is a crucial parameter that determines the performance and efficiency of a battery. It is the measure of opposition to the flow of current within the battery due to various factors such as the electrolyte, electrodes, and connections. A higher internal resistance leads to reduced battery capacity, increased heat generation, and potential damage to the battery.

Understanding and measuring the internal resistance of a battery is essential for optimizing battery performance, ensuring safety, and prolonging battery life. In this article, we will delve into the concept of battery internal resistance, its significance, and the methods used to measure it accurately.

Factors Affecting Battery Internal Resistance

Several factors contribute to the internal resistance of a battery. These include:

-

Electrode materials: The materials used for the electrodes, such as the active materials and current collectors, influence the internal resistance. The conductivity and surface area of the electrodes play a significant role in determining the resistance.

-

Electrolyte: The composition and concentration of the electrolyte affect the ionic conductivity within the battery. A higher ionic conductivity leads to lower internal resistance.

-

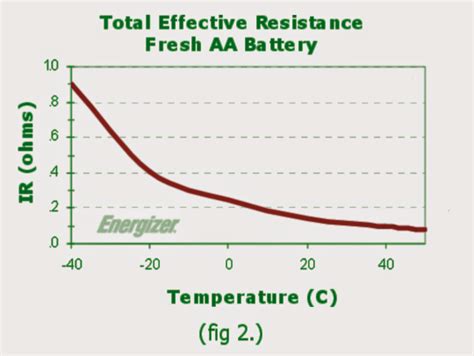

Temperature: Battery internal resistance is temperature-dependent. Generally, lower temperatures increase the internal resistance, while higher temperatures decrease it. However, excessively high temperatures can cause degradation and increase the resistance.

-

State of charge (SOC): The internal resistance of a battery varies with its state of charge. It is typically higher at low and high SOC levels compared to the middle range.

-

Age and cycle life: As a battery ages and undergoes repeated charge-discharge cycles, its internal resistance tends to increase due to various degradation mechanisms such as electrode deterioration and electrolyte depletion.

Methods for Measuring Battery Internal Resistance

There are several methods used to measure the internal resistance of a battery. Each method has its advantages and limitations. Let’s explore some of the commonly used techniques:

1. DC Load Test

The DC load test is a simple and widely used method for measuring battery internal resistance. It involves applying a known load to the battery and measuring the voltage drop across the battery terminals. The internal resistance can be calculated using Ohm’s law:

Internal Resistance = Voltage Drop / Load Current

To perform a DC load test:

1. Fully charge the battery and allow it to rest for a specified period (e.g., 30 minutes).

2. Connect a known load (e.g., a resistor) across the battery terminals.

3. Measure the voltage drop across the battery terminals using a voltmeter.

4. Calculate the internal resistance using the formula above.

| Parameter | Value |

|---|---|

| Battery Voltage | 12.6 V |

| Load Resistance | 10 Ω |

| Voltage Drop | 0.5 V |

| Load Current | 0.05 A |

| Internal Resistance | 10 Ω |

The DC load test provides a simple and quick estimation of the internal resistance. However, it has limitations, such as the need for a fully charged battery and the influence of the load current on the measurement.

2. AC Impedance Spectroscopy

AC impedance spectroscopy is a more advanced technique for measuring battery internal resistance. It involves applying a small AC signal to the battery and measuring the resulting voltage and current responses over a range of frequencies. The impedance of the battery is then calculated using complex mathematical analysis.

AC impedance spectroscopy provides detailed information about the battery’s internal resistance, including the contributions from different components such as the electrodes, electrolyte, and interfaces. It allows for the separation of resistive and capacitive components of the impedance.

To perform AC impedance spectroscopy:

1. Connect the battery to an impedance analyzer or potentiostat.

2. Apply a small AC signal (e.g., 10 mV) over a range of frequencies (e.g., 1 mHz to 100 kHz).

3. Measure the voltage and current responses at each frequency.

4. Analyze the data using specialized software to obtain the impedance spectrum.

| Frequency (Hz) | Impedance (Ω) |

|---|---|

| 1 | 50.2 |

| 10 | 45.7 |

| 100 | 42.1 |

| 1000 | 38.5 |

| 10000 | 35.2 |

AC impedance spectroscopy provides a comprehensive characterization of the battery’s internal resistance. However, it requires specialized equipment and expertise in data analysis.

3. Pulse Load Test

The pulse load test is another method for measuring battery internal resistance. It involves applying a short-duration, high-current pulse to the battery and measuring the voltage response. The internal resistance can be calculated from the voltage drop during the pulse.

To perform a pulse load test:

1. Connect the battery to a pulse load tester or a specialized battery analyzer.

2. Apply a short-duration (e.g., 10 ms), high-current pulse to the battery.

3. Measure the voltage drop during the pulse using a high-speed data acquisition system.

4. Calculate the internal resistance using the formula:

Internal Resistance = Voltage Drop / Pulse Current

| Parameter | Value |

|---|---|

| Battery Voltage | 12.6 V |

| Pulse Current | 10 A |

| Pulse Duration | 10 ms |

| Voltage Drop | 0.2 V |

| Internal Resistance | 0.02 Ω |

The pulse load test provides a dynamic measurement of the battery’s internal resistance under high-current conditions. It simulates real-world scenarios where the battery experiences sudden load changes. However, it requires specialized equipment capable of generating and measuring short-duration, high-current pulses.

Interpreting Battery Internal Resistance Measurements

Once the internal resistance of a battery is measured, it is essential to interpret the results correctly. The interpretation depends on the specific battery chemistry, application, and desired performance criteria.

Generally, a lower internal resistance is desirable for better battery performance. It indicates that the battery can deliver higher currents with minimal voltage drop, resulting in improved efficiency and reduced heat generation.

However, it is important to compare the measured internal resistance with the manufacturer’s specifications or established benchmarks for the specific battery type. Deviations from the expected values can indicate potential issues such as degradation, manufacturing defects, or improper operating conditions.

Monitoring the internal resistance over time can also provide valuable insights into the battery’s health and aging. An increasing trend in internal resistance may indicate the need for battery replacement or maintenance.

Frequently Asked Questions (FAQ)

-

What is the typical internal resistance of a lithium-ion battery?

The typical internal resistance of a lithium-ion battery varies depending on its capacity and design. Generally, it ranges from a few milliohms to tens of milliohms. For example, a 2000 mAh lithium-ion battery may have an internal resistance of around 50-100 mΩ. -

Can high internal resistance cause a battery to fail?

Yes, high internal resistance can lead to battery failure. It reduces the battery’s ability to deliver current, causes voltage drops, and generates excessive heat. Over time, high internal resistance can cause permanent damage to the battery, leading to reduced capacity and potential safety issues. -

How often should I measure the internal resistance of my battery?

The frequency of measuring internal resistance depends on the application and the criticality of the battery’s performance. For critical applications, such as in aerospace or medical devices, regular monitoring (e.g., every few months) is recommended. For general-purpose batteries, measuring internal resistance during routine maintenance or when performance issues are observed can be sufficient. -

Can I measure the internal resistance of a partially discharged battery?

It is generally recommended to measure the internal resistance of a fully charged battery to obtain accurate and consistent results. Measuring the internal resistance of a partially discharged battery may introduce variations due to the state of charge and can lead to misleading interpretations. -

Are there any safety precautions to consider when measuring battery internal resistance?

Yes, safety precautions are essential when working with batteries. Always follow the manufacturer’s guidelines and use appropriate personal protective equipment (PPE) such as gloves and eye protection. Ensure proper ventilation and avoid short-circuiting the battery terminals. If using specialized equipment, follow the operating instructions carefully and ensure the equipment is calibrated and in good working condition.

Conclusion

Battery internal resistance is a critical parameter that determines the performance, efficiency, and health of a battery. Understanding and measuring internal resistance is essential for optimizing battery systems, ensuring safety, and prolonging battery life.

Various methods, such as the DC load test, AC impedance spectroscopy, and pulse load test, can be used to measure battery internal resistance accurately. Each method has its advantages and limitations, and the choice depends on the specific application and available resources.

Interpreting internal resistance measurements requires knowledge of the battery chemistry, application requirements, and established benchmarks. Monitoring the internal resistance over time can provide valuable insights into battery health and aging.

By understanding and effectively measuring battery internal resistance, engineers, researchers, and battery users can make informed decisions, optimize battery performance, and ensure the reliable and safe operation of battery-powered systems.

Leave a Reply