Printed circuit boards (PCBs) are essential components in virtually all modern electronic devices. As an electronics designer or engineer, you may need to have PCBs fabricated for prototypes or production runs. Rather than using an overseas PCB manufacturer, you may want to find a PCB production facility close to where you live or work. There are several good reasons to use a local PCB manufacturer:

- Faster turnaround times – Local manufacturers can often produce PCBs much quicker since you avoid overseas shipping. This helps accelerate the development process.

- Easier communication – When the PCB facility is in the same time zone, it’s simpler to discuss requirements and address issues via phone or email.

- Lower minimum order quantities – Overseas manufacturers typically have high minimum orders because of the required logistics. Local shops may be able to produce smaller quantities.

- Proximity – You can visit the production facility to inspect and qualify the manufacturing processes and quality procedures.

- ITAR compliance – Some defense projects require ITAR-compliant PCB production done by US citizens only. Local manufacturers specializing in this are beneficial.

- Reduced shipping costs – For larger production runs, not having PCBs shipped internationally can represent major cost savings.

- Quick turnaround on revisions – If you find issues with the PCB or layout and need modifications, a local manufacturer enables fast turnaround.

How to find PCB manufacturers in your area

If you’ve decided that using a locally-based PCB producer makes sense for your project, how do you go about finding appropriate manufacturers? Here are some methods to locate PCB fabrication companies near where you live or work:

Search engines

The easiest starting point is using Google or any major search engine. Try searches like:

- PCB manufacturing “City, State”

- PCB fabrication “City, State”

- Printed circuit board manufacturer “City, State”

Where “City, State” is your location. This should turn up a few options. Look through the first few pages of results.

PCB manufacturer directories

There are websites that maintain lists of PCB fabricators worldwide, searchable by location. These include:

Browse their directory listings filtered by your state or city.

Business directories

Check general business directories or manufacturing directories focused on your area. Some options:

- Google Maps results for “PCB manufacturing” in your city.

- Yelp filtered for your location.

- Manta has a PCB manufacturing category.

- Local Chamber of Commerce business directory.

- City or state business license directories.

Local supply chain

If you work with any electronics equipment manufacturers in your area, find out where they have their PCBs built. Chances are there are local shops they use that can also help you.

Electronics industry associations

State or city associations like the California Electronics Association or the Minnesota Electronics Manufacturing Network are good resources. They may list members providing PCB fabrication locally.

Product design firms

Product design companies and independent engineers/inventors needing PCB prototyping and manufacturing are likely to know their local suppliers. Talk to any you have a relationship with and ask who they use.

Trade shows

At larger electronics industry trade exhibitions, many PCB fabrication companies will exhibit. Attending shows like DesignCon, IPC APEX Expo, or MD&M allows you to find suppliers and meet them in person.

Referrals

Word-of-mouth referrals from colleagues who have designed electronics locally can be very valuable. Ask around at your company or amongst your industry peers.

Evaluating potential PCB manufacturers

Once you’ve found multiple PCB fabrication companies in your area, you’ll want to vet them further to choose the optimal partner for your needs. Here are key factors to consider in your decision process:

Capabilities

- What PCB materials do they work with? Typical options are FR-4, Rogers, Teflon, aluminum, etc.

- What’s the minimum/maximum board size they can manufacture?

- How many PCB layers can they produce? From 2 to perhaps over 20.

- What minimum track/space width can they achieve? Down to 2 mil?

- Do they offer via filling and plating? Blind/buried vias? Microvias?

- What finishes are available? Immersion tin, ENIG, silver, gold, etc.

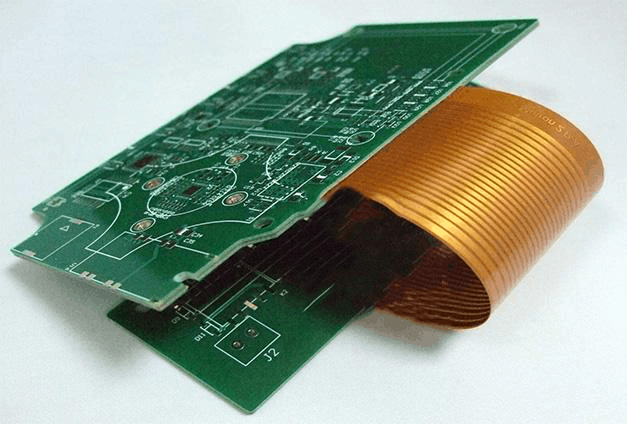

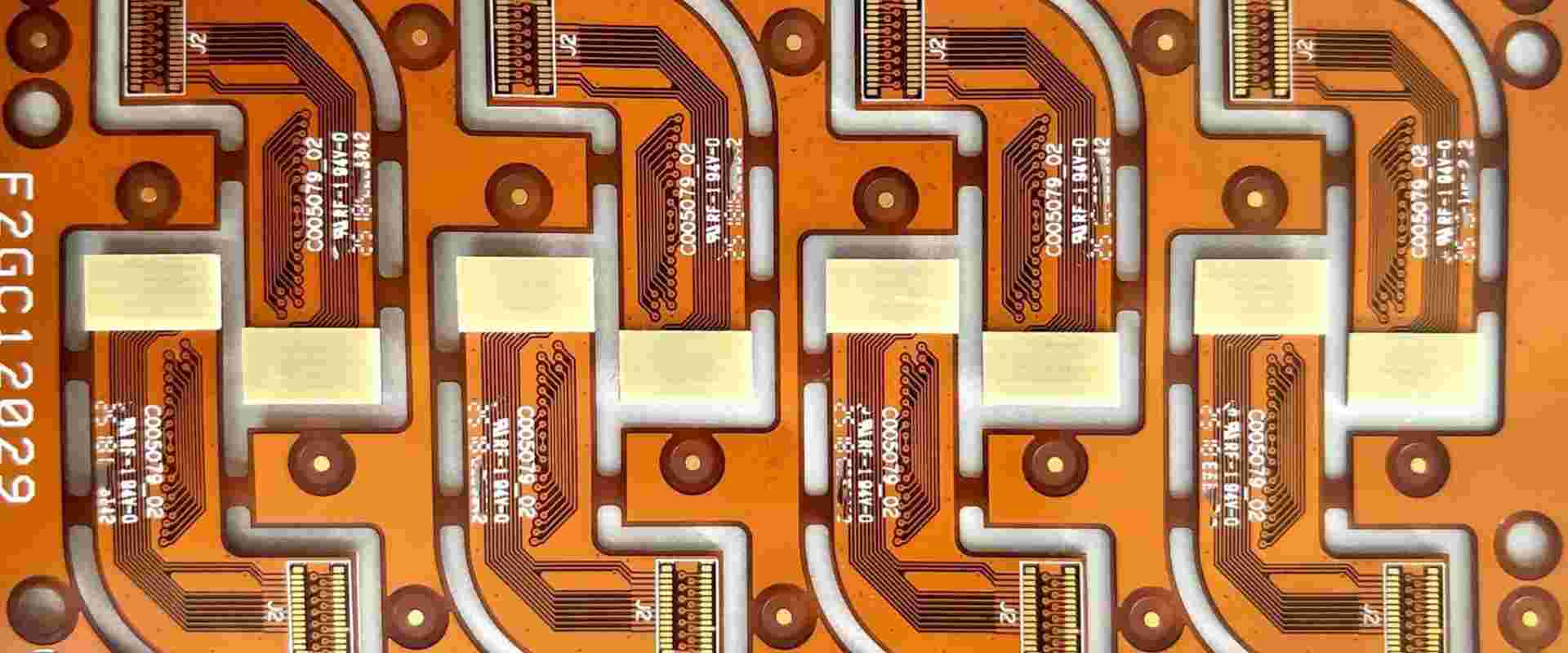

- Can they build flex PCBs or rigid-flex boards?

- Do they handle PCB assembly as well as bare boards?

Quality

- Are they ISO 9001 certified? Or ISO 13485 for medical boards?

- Do they maintain acceptable process capabilities and tolerances?

- What test and inspection methods do they use?

- How do they manage counterfeit components in their assembly?

Services

- Is design for manufacturing (DFM) review offered?

- Can they fabricate from customer-provided CAD files?

- Do they provide layout or design services if needed?

- Is electrical/functional testing available?

- Do they offer quick-turn prototypes as well as production?

- How is post-delivery support, e.g. for repair issues?

Pricing and delivery

- What is the typical lead time? Can they meet your schedule?

- How much NRE cost for new designs?

- What are the costs for volume production?

- Are there quantity discounts or rebates?

- Is expedited manufacturing available for a premium?

- What courier services do they integrate with?

Qualifications

- How long have they been manufacturing PCBs? Are they financially stable?

- What key customers do they have as references?

- Do they maintain quality management certifications?

- Do they handle any military or aerospace work?

- Are they ITAR-registered if needed?

Security

- Are they willing to sign non-disclosure agreements?

- Do they have physical and IT security controls?

- Can they accommodate any special security or IP requirements?

By having discussions and asking these sorts of questions, you can determine which manufacturer is the best fit. Try to visit their facility if possible as well.

Getting PCB fabrication quotes

Once you’ve narrowed down the list of potential suppliers, you’ll want to get fabrication quotes for comparison. Here’s how to get started:

Provide PCB design files

Supply Gerber files, drill data, schematics, bill of materials, layer stackup info, and any other relevant data about your design. This gives the manufacturer the details they need.

Specify quantity required

Make sure you clearly state how many boards you need – is it 10 prototypes? 1,000 for production? This will dramatically affect pricing.

Define special requirements

Mention any special requirements like super-fine lines, impedance control, buried vias, etc. This may increase costs.

Request applicable options

See what options are available and make sure to get pricing on those you want, which might include:

- Different PCB finishes like immersion silver, ENIG, etc.

- Solder mask color choices.

- Impedance controlled dielectric materials.

- Higher TG laminates for temperature tolerance.

- Different thicknesses for the PCB core dielectric.

- Plated slots or edge plating.

Ask about expedited delivery

If you need boards very quickly, request pricing for their fastest turnaround options. There is usually a premium for this.

Inquire about design assistance

If you need help with layout, ask what they would charge for engineering time to support you.

Shipping fees

Check costs for shipping your finished PCBs to your location, which varies based on quantity.

Once you receive quotes from each potential supplier, you can compare on total cost, availability, and other factors to pick the winner.

Tips for smooth PCB production

Here are some tips to help make sure your PCB fabrication and assembly process goes smoothly when working with a manufacturer:

Optimize design for manufacturability

Work to design your PCB so it can be easily and reliably manufactured. Allow adequate spacing, annular rings, etc.

Provide comprehensive documentation

Supply detailed schematics, well-organized bill of materials, assembly drawings, and full fabrication notes to reduce errors.

Build in inspection points

Add fiducials and testpoints in your design to support in-process optical inspection and electrical testing during fabrication.

Plan for reproducibility

Avoid one-off parts and processes. Use standard components and consistent, repeatable methods.

Communicate clearly

Be thorough, precise and proactive in discussing all requirements with your manufacturer’s engineers.

Stay hands-on involved

Expect to review work in progress, inspect results and provide feedback to the manufacturer throughout the process.

Check certifications for compliance

If your product has regulatory requirements, be sure all qualifications are met through auditor certs or other documented evidence.

Allow time for quality management

Build in adequate time for comprehensive testing, inspection and revision control to meet your expectations.

Build a partnership

Develop a collaborative trusted relationship with your fabricator rather than just a transactional vendor.

Questions and answers about local PCB manufacturing

Here are answers to some frequently asked questions about finding and working with PCB manufacturers in your area:

How much does PCB manufacturing cost for prototyping vs production?

For prototype volumes, expect costs ranging from $1,500 – $5,000 for small, simple boards up to $25,000 for large, complex designs. For medium to high volume production, cost can be under $100 per board for basic designs but still $2,000+ for intricate boards.

What PCB design software do manufacturers prefer?

Most accept standard formats like Gerber, DXF, and IPC-2581. KiCad, Eagle, Altium, OrCAD, PADS, and Allegro are common among designers.

Can PCB houses handle BGA packages and other advanced components?

Yes, many local manufacturers support advanced parts like BGAs, 01005 passives, and high pin-count chips for complex designs. But always discuss your BOM.

How long does PCB fabrication usually take?

With local producers, prototypes can be delivered in 1-2 weeks. Production timelines vary depending on quantities and complexity but 5-6 weeks is typical.

Expedited delivery can be as fast as 24 hours for an additional fee.

What tolerances do domestic PCB manufacturers hold?

Typical tolerances local shops hold are:

- Line width and space: +/- 5%

- Hole size: +/- 10%

- Hole to pad concentricity: 25% of hole size

- Hole plating thickness: +/- 10%

Are US-made PCBs of higher quality than those made overseas?

Not categorically, but local manufacturers are often held to higher expectations of quality by customers and resultingly invest in process and quality control. But results vary by company.

Conclusion

Finding a printed circuit board manufacturer in close proximity to you provides key benefits like rapid prototypes, lower costs, and better communication. With the abundance of PCB fabrication companies across the US, you should have multiple options reasonably close by once you search directories, business listings, and referrals from your network.

Vet each potential supplier on their capabilities, quality system, cost competitiveness, and qualifications to pick the right partner. Provide comprehensive design documentation and work collaboratively with them through the build process for optimal results. Following these tips will help you locate a PCB producer nearby that can fully meet your needs for either prototypes or volume manufacturing.

Leave a Reply