Understanding Quick Turn PCB Assembly

Before diving into the selection criteria, let’s first understand what quick turn PCB assembly entails.

What is Quick Turn PCB Assembly?

Quick turn PCB assembly refers to the rapid fabrication and assembly of printed circuit boards within a short turnaround time, typically ranging from 24 hours to 5 business days. This service caters to urgent projects, prototyping needs, and low-volume production runs.

Benefits of Quick Turn PCB Assembly

- Faster time-to-market

- Accelerated prototyping and testing

- Reduced inventory costs

- Flexibility in design changes

- Improved responsiveness to market demands

Key Factors to Consider When Choosing a Quick Turn PCB Assembly Service

1. Turnaround Time

One of the primary reasons for opting for quick turn PCB assembly is the fast turnaround time. When evaluating service providers, consider the following:

- Guaranteed turnaround time for different PCB complexity levels

- Availability of expedited services for extremely urgent projects

- Ability to meet tight deadlines consistently

| Turnaround Time | PCB Complexity | Suitable For |

|---|---|---|

| 24-48 hours | Simple, 1-2 layers | Urgent prototyping |

| 3-5 business days | Moderate, 4-6 layers | Low-volume production |

| 5-7 business days | Complex, 8+ layers | High-density designs |

2. Manufacturing Capabilities

Assess the manufacturing capabilities of the quick turn PCB assembly service provider to ensure they can handle your specific requirements:

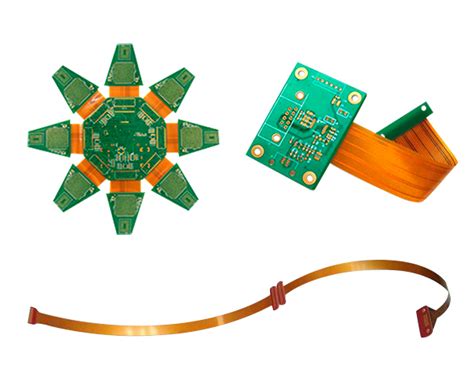

- PCB fabrication technologies (e.g., HDI, flex, rigid-flex)

- Supported PCB materials (e.g., FR-4, Rogers, polyimide)

- Multilayer capabilities (e.g., 2-layer, 4-layer, 8-layer)

- Minimum feature sizes (e.g., trace width, spacing, hole size)

- Surface finishes (e.g., HASL, ENIG, OSP)

3. Assembly Options

Consider the assembly options offered by the service provider to meet your project needs:

- Through-hole (THT) and surface mount (SMT) assembly

- Mixed-technology assembly (combining THT and SMT)

- Automated optical inspection (AOI) and X-ray inspection

- Conformal coating and potting

- Box build and system integration

4. Quality Control and Certifications

Ensure that the quick turn PCB assembly service provider adheres to strict quality control measures and holds relevant certifications:

- ISO 9001 certification for quality management systems

- IPC standards (e.g., IPC-A-610, IPC-J-STD-001)

- UL and RoHS compliance

- Automated testing and inspection procedures

- Documented quality control processes

5. Customer Support and Communication

Effective communication and reliable customer support are crucial when working with a quick turn PCB assembly service provider:

- Dedicated project manager or point of contact

- Clear and responsive communication channels

- Regular project updates and status tracking

- Technical support and design assistance

- Flexible order management and revision control

6. Pricing and Cost-Effectiveness

While quick turn PCB assembly services may come at a premium, it’s essential to consider the overall cost-effectiveness:

- Competitive pricing for quick turn services

- Volume discounts for larger orders

- Cost-saving opportunities through design optimization

- Transparent pricing structure and quotes

- Shipping and logistics costs

7. Industry Experience and Reputation

Evaluate the service provider’s industry experience and reputation to gauge their reliability and expertise:

- Years of experience in PCB fabrication and assembly

- Portfolio of successful projects and case studies

- Client testimonials and references

- Industry partnerships and certifications

- Participation in industry events and conferences

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity (MOQ) for quick turn PCB assembly?

Most quick turn PCB assembly service providers offer low MOQs, often starting from a single prototype. However, MOQs may vary depending on the complexity of the PCB design and the specific service provider.

2. Can I request expedited shipping for my quick turn PCB assembly order?

Yes, many service providers offer expedited shipping options for quick turn orders. Be sure to discuss your shipping requirements with the service provider and factor in the additional costs.

3. What files do I need to provide for quick turn PCB assembly?

Typically, you will need to provide Gerber files, bill of materials (BOM), and assembly drawings. Some service providers may also accept ODB++ or IPC-2581 files. It’s best to consult with the service provider for their specific file requirements.

4. How can I ensure the quality of my quick turn PCB assembly?

To ensure quality, choose a service provider with strong quality control measures, certifications (e.g., ISO 9001, IPC standards), and automated inspection capabilities. Additionally, provide clear and comprehensive design files and engage in open communication with the service provider throughout the process.

5. Can I request design assistance for my quick turn PCB assembly project?

Many quick turn PCB assembly service providers offer design assistance and support. They can help optimize your PCB design for manufacturability, cost-effectiveness, and reliability. Don’t hesitate to leverage their expertise to improve your project outcomes.

Conclusion

Choosing the right quick turn PCB assembly service is crucial for the success of your electronics projects. By considering factors such as turnaround time, manufacturing capabilities, assembly options, quality control, customer support, pricing, and industry experience, you can make an informed decision that aligns with your project requirements and business goals.

Remember, a reliable and experienced quick turn PCB assembly service provider can be a valuable partner in bringing your products to market faster, reducing costs, and ensuring high-quality results. Take the time to evaluate your options carefully and engage in open communication with potential service providers to find the best fit for your needs.

By leveraging the benefits of quick turn PCB assembly and partnering with a trusted service provider, you can accelerate your product development cycles, respond quickly to market demands, and maintain a competitive edge in today’s fast-paced electronics industry.

Leave a Reply