Introduction to PCB Kits

A PCB (Printed Circuit Board) kit is a package containing all the necessary components and instructions to assemble a functional electronic circuit. PCB kits are an excellent way for beginners to learn about electronics and gain hands-on experience in assembling and soldering components. In this comprehensive guide, we will walk you through the process of building a PCB kit, from understanding the components to testing the completed circuit.

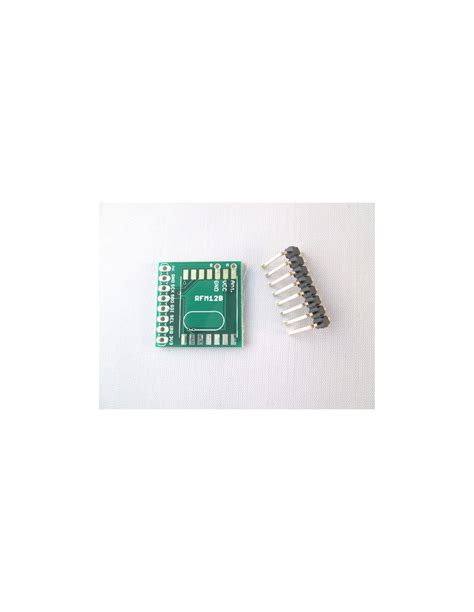

What is a PCB Kit?

A PCB kit typically includes a pre-designed and manufactured PCB, along with all the required electronic components, such as resistors, capacitors, diodes, transistors, and integrated circuits (ICs). The kit also includes a detailed instruction manual or guide that explains the assembly process step by step.

PCB kits come in various levels of complexity, ranging from simple projects like LED blinkers to more advanced projects like digital clocks or Arduino-based devices. Choosing the right kit for your skill level is crucial to ensure a successful and enjoyable learning experience.

Benefits of Building a PCB Kit

Building a PCB kit offers several benefits for beginners:

- Hands-on learning: Assembling a PCB kit allows you to gain practical experience in electronics assembly and soldering.

- Understanding circuit diagrams: Working with a PCB kit helps you understand how to read and interpret circuit diagrams and schematics.

- Troubleshooting skills: Building a PCB kit develops your troubleshooting skills as you learn to identify and fix issues that may arise during the assembly process.

- Sense of accomplishment: Successfully completing a PCB kit project provides a sense of accomplishment and boosts your confidence in working with electronics.

Tools and Equipment Required

Before you start building your PCB kit, ensure that you have the following tools and equipment:

- Soldering iron (20-40 watts)

- Soldering stand

- Solder wire (lead-free, rosin-core, 0.5-0.8 mm diameter)

- Solder wick or desoldering pump

- Wire cutters

- Needle-nose pliers

- Tweezers

- Multimeter

- Safety glasses

- Well-ventilated workspace

Understanding the Components

A typical PCB kit includes various electronic components. Familiarize yourself with these components before starting the assembly process:

Resistors

Resistors are two-terminal components that resist the flow of electric current. They are used to control the voltage and current in a circuit. Resistor values are measured in ohms (Ω) and are indicated by color codes on the component body.

Capacitors

Capacitors are two-terminal components that store electrical energy in an electric field. They are used for filtering, smoothing, and decoupling in electronic circuits. Capacitor values are measured in farads (F) and are often printed on the component body.

Diodes

Diodes are two-terminal components that allow current to flow in only one direction. They are used for rectification, protection, and isolation in electronic circuits. Common types of diodes include rectifier diodes, Zener diodes, and light-emitting diodes (LEDs).

Transistors

Transistors are three-terminal components that can amplify or switch electronic signals. They are used for signal amplification, switching, and voltage regulation in electronic circuits. Common types of transistors include bipolar junction transistors (BJTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs).

Integrated Circuits (ICs)

Integrated circuits are miniaturized electronic circuits that contain multiple components, such as transistors, diodes, and resistors, on a single semiconductor chip. They are used for various purposes, such as amplification, signal processing, and digital logic.

Preparing the Workspace

Before starting the assembly process, prepare your workspace:

- Choose a well-ventilated area with good lighting.

- Clean your work surface and ensure it is free from clutter.

- Organize your tools and components for easy access.

- Place your PCB kit components and instruction manual within reach.

Reading the Circuit Diagram

The first step in building a PCB kit is to understand the circuit diagram or schematic. A circuit diagram is a graphical representation of the electronic components and their interconnections in a circuit.

To read a circuit diagram:

- Identify the components: Familiarize yourself with the symbols used for different components, such as resistors, capacitors, diodes, and transistors.

- Follow the connections: Trace the lines connecting the components to understand how they are interconnected.

- Note the component values: Pay attention to the values of resistors, capacitors, and other components, as they are crucial for the proper functioning of the circuit.

Assembling the PCB Kit

Once you have familiarized yourself with the components and the circuit diagram, you can start assembling the PCB kit:

- Place the PCB in your work area with the component side facing up.

- Identify the component locations on the PCB using the reference designators (e.g., R1, C2, D3) printed on the board.

- Insert the components into their respective locations, ensuring that they are oriented correctly (e.g., diodes and electrolytic capacitors have polarity).

- Bend the component leads slightly to hold them in place.

- Double-check the component placement and orientation before soldering.

Soldering the Components

Soldering is the process of joining two metal surfaces using a molten filler metal (solder). To solder the components onto the PCB:

- Heat up your soldering iron and wait for it to reach the desired temperature (usually 300-400°C).

- Clean the soldering iron tip with a damp sponge or brass wool.

- Place the soldering iron tip against the component lead and the PCB pad simultaneously.

- Apply solder to the joint, allowing it to melt and flow around the lead and pad.

- Remove the solder and the soldering iron, and let the joint cool for a few seconds.

- Repeat the process for all the components.

Tips for successful soldering:

- Use a soldering iron with the appropriate wattage and tip size for your project.

- Keep the soldering iron tip clean and tinned with solder.

- Apply heat to the joint for a short duration (2-3 seconds) to avoid damaging the components or the PCB.

- Use a sufficient amount of solder to create a strong and reliable joint, but avoid applying too much, which can cause shorts or bridging between adjacent pads.

Inspecting the Soldered Joints

After soldering all the components, inspect the soldered joints for any defects or issues:

- Check for cold joints: A cold joint appears dull and grainy, indicating insufficient heat or poor solder flow. Reheat and apply more solder to fix a cold joint.

- Look for bridging: Bridging occurs when excess solder accidentally connects adjacent pads or traces. Use a solder wick or desoldering pump to remove the excess solder.

- Ensure mechanical stability: Gently tug on the components to ensure they are securely soldered to the PCB.

Testing the Completed Circuit

After inspecting the soldered joints, it’s time to test the completed circuit:

- Double-check the component placement and orientation.

- Connect the power supply (e.g., battery or DC power adapter) to the appropriate terminals on the PCB.

- Turn on the power supply and observe the circuit’s behavior.

- Use a multimeter to measure voltages, currents, or resistances at various points in the circuit to verify its proper functioning.

If the circuit does not work as expected, follow these troubleshooting steps:

- Recheck the component placement and orientation.

- Inspect the soldered joints for defects or poor connections.

- Verify that the power supply is connected correctly and providing the appropriate voltage.

- Consult the instruction manual or seek assistance from online forums or experienced hobbyists.

Frequently Asked Questions (FAQs)

-

What is the best soldering iron for beginners?

A: For beginners, a soldering iron with adjustable temperature control and a wattage between 20-40 watts is recommended. Popular choices include the Hakko FX-888D, Weller WLC100, and X-Tronic 3020-XTS. -

How do I identify the resistor values?

A: Resistor values are indicated by color codes on the component body. Each color represents a digit or a multiplier. You can use a resistor color code chart or calculator to determine the value based on the color bands. -

Can I substitute components in a PCB kit?

A: It is generally not recommended to substitute components in a PCB kit unless you have a good understanding of the circuit and the component specifications. Substituting components can lead to unexpected behavior or even damage to the circuit. -

How do I avoid damaging components while soldering?

A: To avoid damaging components, use a soldering iron with the appropriate temperature and wattage, apply heat for a short duration (2-3 seconds), and avoid touching the component body with the soldering iron tip. Also, ensure proper ventilation to avoid inhaling solder fumes. -

What should I do if my circuit doesn’t work after assembly?

A: If your circuit doesn’t work after assembly, first visually inspect the PCB for any apparent defects or issues, such as incorrect component placement, poor soldering, or bridging. If you cannot identify the problem, consult the instruction manual, online forums, or seek assistance from experienced hobbyists or electronics professionals.

Conclusion

Building a PCB kit is an excellent way for beginners to learn about electronics and gain hands-on experience in assembling and soldering components. By following this comprehensive guide, you should now have a better understanding of the tools, components, and processes involved in building a PCB kit.

Remember to start with a kit that matches your skill level, read the instructions carefully, and take your time during the assembly process. With practice and patience, you’ll soon be able to tackle more complex projects and expand your knowledge of electronics.

Happy building!

| Component | Purpose |

|---|---|

| Resistors | Control voltage and current in a circuit |

| Capacitors | Store electrical energy for filtering and smoothing |

| Diodes | Allow current to flow in one direction for rectification |

| Transistors | Amplify or switch electronic signals |

| Integrated Circuits (ICs) | Miniaturized electronic circuits for various functions |

| Tool | Purpose |

|---|---|

| Soldering Iron | Melt solder to join components to the PCB |

| Wire Cutters | Cut component leads and wires |

| Needle-nose Pliers | Bend component leads and assist in component placement |

| Tweezers | Handle small components and assist in placement |

| Multimeter | Measure voltage, current, and resistance in a circuit |

Leave a Reply