What is the Rayming PCB Calculator?

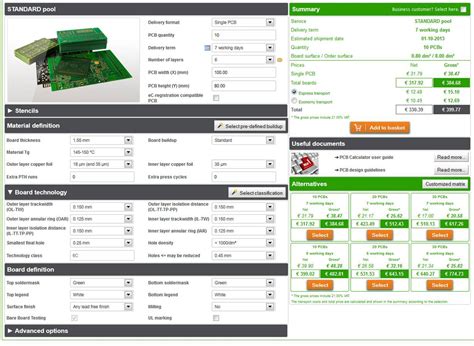

The Rayming PCB Calculator is an online tool that allows you to quickly and easily calculate the cost of manufacturing printed circuit boards (PCBs). It provides instant quotations based on your PCB specifications, helping you budget your projects effectively. The calculator also offers data analysis features to help you optimize your PCB designs for cost-efficiency.

How to use the Rayming PCB Calculator

Using the Rayming PCB Calculator is a simple 3-step process:

- Enter your PCB specifications

- Get an instant quotation

- Analyze the cost breakdown

Step 1: Enter your PCB specifications

The first step is to input the details of your PCB into the calculator. You will need to provide the following information:

- Number of layers (1-16)

- PCB dimensions (length x width)

- Quantity

- PCB thickness

- Copper weight

- Surface finish

- Solder mask color

- Silkscreen color

- Minimum hole size

- Minimum trace/space

- Gold Fingers

- Material (FR-4, aluminum, flexible, etc.)

Here is an example of the input fields you will see:

| Parameter | Value |

|---|---|

| Layers | 2 |

| Length | 100 mm |

| Width | 80 mm |

| Quantity | 100 |

| Thickness | 1.6 mm |

| Copper | 1 oz |

| Finish | HASL |

| Mask | Green |

| Silkscreen | White |

| Min Hole | 0.3 mm |

| Trace/Space | 6/6 mil |

| Gold Fingers | No |

| Material | FR-4 |

Be sure to double-check that all the information you have entered is correct before proceeding to the next step.

Step 2: Get an instant quotation

Once you have input your PCB specifications, simply click the “Calculate” button and the Rayming PCB Calculator will generate an instant quotation for you. The quotation will include the following information:

- Unit price

- Tooling cost (if applicable)

- Shipping cost

- Total cost

- Lead time

For example, based on the PCB specifications we entered in Step 1, the quotation might look something like this:

| Item | Cost |

|---|---|

| Unit Price | $5.00 |

| Tooling | $100.00 |

| Shipping | $50.00 |

| Total | $650.00 |

| Lead Time | 5 days |

The quotation is valid for 24 hours, giving you time to review and compare prices from other manufacturers if needed. If you are happy with the quotation, you can proceed to place your order directly through the Rayming website.

Step 3: Analyze the cost breakdown

In addition to providing instant quotations, the Rayming PCB Calculator also offers data analysis features to help you understand the cost drivers of your PCB. After generating a quotation, you can click on the “Cost Analysis” tab to see a detailed breakdown of the costs.

The cost analysis will show you the percentage of the total cost that each component contributes, such as:

- PCB fabrication

- Solder mask

- Silkscreen

- Surface finish

- Drill holes

- Slots/cutouts

- Testing

- Shipping

For example, the cost breakdown for our sample PCB might look like this:

| Component | Percentage |

|---|---|

| Fabrication | 60% |

| Solder Mask | 10% |

| Silkscreen | 5% |

| Surface Finish | 10% |

| Drill Holes | 5% |

| Slots/Cutouts | 3% |

| Testing | 2% |

| Shipping | 5% |

By understanding which components are driving the cost of your PCB, you can make informed decisions about where to optimize your design. For example, if the solder mask is a significant cost driver, you might consider using a different color or removing it altogether if it is not essential for your application.

Tips for optimizing PCB cost with the Rayming PCB Calculator

Here are some tips for using the Rayming PCB Calculator to optimize the cost of your PCBs:

-

Minimize the number of layers: Each additional layer adds complexity and cost to the manufacturing process. Use the minimum number of layers required for your design.

-

Reduce PCB dimensions: Larger PCBs are more expensive to manufacture. Try to design your PCB to be as small as possible while still meeting your functional requirements.

-

Increase quantity: The unit cost of PCBs decreases as the quantity increases. If you anticipate needing a large number of PCBs, consider ordering them all at once to take advantage of volume discounts.

-

Use standard thicknesses and materials: Non-standard thicknesses and materials may require special tooling and processing, which can increase costs. Stick to standard options whenever possible.

-

Avoid tight tolerances: Tight tolerances for trace/space and hole sizes can increase manufacturing complexity and cost. Use the widest tolerances that will still meet your design requirements.

By following these tips and using the Rayming PCB Calculator to analyze the cost drivers of your PCB, you can optimize your design for cost-efficiency and get the best value for your money.

Frequently Asked Questions (FAQ)

-

Is the Rayming PCB Calculator free to use?

Yes, the Rayming PCB Calculator is completely free to use. You do not need to create an account or provide any payment information to access the calculator. -

How accurate are the quotations generated by the calculator?

The quotations generated by the Rayming PCB Calculator are based on real-time market prices and are highly accurate. However, they are intended for reference purposes only and may be subject to change based on the specific requirements of your project. -

Can I place an order directly through the calculator?

No, the Rayming PCB Calculator is a quotation tool only. To place an order, you will need to visit the Rayming website and follow their standard ordering process. -

What if I need help using the calculator or have questions about my PCB design?

If you need assistance using the Rayming PCB Calculator or have questions about your PCB design, you can contact the Rayming support team through their website. They have experienced engineers who can provide guidance and advice to help you optimize your design for cost and manufacturability. -

Are there any limitations to the PCBs that can be quoted using the calculator?

The Rayming PCB Calculator is designed to handle a wide range of PCB specifications, but there may be some limitations based on the capabilities of Rayming’s manufacturing facilities. If you have a particularly complex or unusual PCB design, it is best to contact Rayming directly to discuss your requirements and get a custom quotation.

Conclusion

The Rayming PCB Calculator is a powerful tool for anyone involved in the design and manufacture of PCBs. By providing instant quotations and cost analysis features, it helps you optimize your designs for cost-efficiency and make informed decisions about your PCB projects. Whether you are a hobbyist working on a personal project or an engineering manager overseeing a large-scale production run, the Rayming PCB Calculator is an essential resource that can save you time and money. Try it out today and see how it can help streamline your PCB workflow!

Leave a Reply