Introduction to Flexible Circuitry

Flexible circuitry, also known as flex circuits or flexible printed circuit boards (PCBs), is a technology that has revolutionized the electronics industry. Unlike traditional rigid PCBs, flexible circuits are designed to bend and flex without breaking or losing their electrical properties. This unique characteristic makes them ideal for applications where space is limited, or where the device needs to conform to a particular shape.

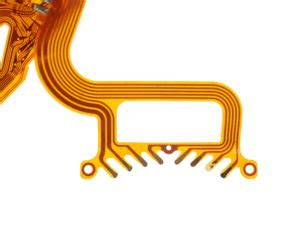

Flexible circuits consist of a thin, flexible substrate made of materials such as polyimide or polyester, with conductive traces printed or etched onto the surface. These traces are typically made of copper, although other materials such as silver or gold may be used for specialized applications. The substrate is then covered with a protective layer, such as a cover lay or solder mask, to insulate and protect the conductive traces.

History of Flexible Circuitry

The concept of flexible circuitry dates back to the early 20th century, with the first patent for a flexible printed circuit being filed in 1903 by Albert Hanson, a German inventor. However, it wasn’t until the 1950s that the technology began to gain traction, with the development of the first practical flexible circuits for use in military applications.

In the 1960s, NASA began using flexible circuits in their space programs, as they offered significant advantages over traditional rigid PCBs in terms of weight and space savings. This led to further advancements in the technology, with the development of new materials and manufacturing processes that improved the reliability and performance of flexible circuits.

Today, flexible circuits are used in a wide range of applications, from consumer electronics to medical devices to aerospace and defense systems. They have become an essential component in many modern electronic devices, enabling the development of smaller, lighter, and more complex systems.

Advantages of Flexible Circuitry

Space Savings

One of the primary advantages of flexible circuitry is the ability to save space in electronic devices. Because flexible circuits can bend and conform to the shape of the device, they can be used in applications where traditional rigid PCBs would not fit. This is particularly important in modern electronics, where the trend is towards smaller, more compact devices.

For example, in smartphones and wearable devices, flexible circuits can be used to connect the various components, such as the display, battery, and sensors, while taking up minimal space. This allows for the development of thinner, more streamlined devices that are more comfortable to wear and use.

Weight Savings

In addition to space savings, flexible circuits also offer significant weight savings compared to traditional rigid PCBs. This is because the substrate material used in flexible circuits is much thinner and lighter than the FR-4 material used in rigid PCBs.

This weight savings is particularly important in aerospace and defense applications, where every gram counts. By using flexible circuits instead of rigid PCBs, designers can reduce the overall weight of the system, which can lead to improved fuel efficiency and performance.

Improved Reliability

Flexible circuits also offer improved reliability compared to traditional rigid PCBs. Because they are designed to bend and flex, they are less susceptible to damage from vibration and shock. This is particularly important in applications where the device may be subject to harsh environments or rough handling.

In addition, flexible circuits can be designed with redundant traces and connections, which can improve the overall reliability of the system. If one trace or connection fails, the redundant trace can take over, ensuring that the system continues to function properly.

Enhanced Design Freedom

Another advantage of flexible circuitry is the enhanced design freedom it offers. Because flexible circuits can bend and conform to the shape of the device, designers have more flexibility in terms of component placement and routing.

This can lead to more efficient designs that are easier to manufacture and assemble. It also allows for the development of more complex systems that would not be possible with traditional rigid PCBs.

Cost Savings

Finally, flexible circuits can offer significant cost savings compared to traditional rigid PCBs. This is because the manufacturing process for flexible circuits is often simpler and more automated than for rigid PCBs.

In addition, because flexible circuits can be designed to conform to the shape of the device, they can often be manufactured in a single piece, reducing the number of components and connections required. This can lead to reduced assembly time and costs.

Applications of Flexible Circuitry

Flexible circuitry has found use in a wide range of applications, from consumer electronics to medical devices to aerospace and defense systems. Some of the most common applications include:

Consumer Electronics

Flexible circuits are widely used in consumer electronics, such as smartphones, tablets, and wearable devices. They are particularly useful in applications where space is limited, or where the device needs to conform to a particular shape.

For example, in smartwatches, flexible circuits can be used to connect the various components, such as the display, battery, and sensors, while taking up minimal space. This allows for the development of thinner, more comfortable devices that can be worn all day.

Medical Devices

Flexible circuits are also widely used in medical devices, such as hearing aids, pacemakers, and insulin pumps. They are particularly useful in applications where the device needs to be implanted in the body, as they can conform to the shape of the body and reduce the risk of tissue damage.

For example, in cochlear implants, flexible circuits are used to connect the external processor to the implanted electrode array. This allows for a more comfortable and secure fit, while also reducing the risk of damage to the delicate cochlear structures.

Automotive Electronics

Flexible circuits are increasingly being used in automotive electronics, such as dashboard displays, infotainment systems, and advanced driver assistance systems (ADAS). They offer significant advantages over traditional rigid PCBs in terms of space savings and design freedom.

For example, in dashboard displays, flexible circuits can be used to connect the various components, such as the LCD panel, touchscreen, and sensors, while conforming to the shape of the dashboard. This allows for the development of more integrated and streamlined systems that are easier to install and maintain.

Aerospace and Defense

Flexible circuits are widely used in aerospace and defense applications, where reliability and performance are critical. They offer significant advantages over traditional rigid PCBs in terms of weight savings and design freedom.

For example, in satellites and spacecraft, flexible circuits can be used to connect the various components, such as the solar panels, batteries, and sensors, while taking up minimal space and weight. This allows for the development of more efficient and reliable systems that can withstand the harsh environment of space.

Challenges and Limitations of Flexible Circuitry

Despite the many advantages of flexible circuitry, there are also some challenges and limitations that need to be considered.

Material Selection

One of the main challenges in designing flexible circuits is selecting the appropriate materials for the substrate and conductive traces. The materials need to be flexible enough to bend and conform to the shape of the device, while also being able to withstand the stresses and strains of repeated flexing.

In addition, the materials need to be compatible with the manufacturing process and the intended application. For example, in medical devices, the materials need to be biocompatible and able to withstand sterilization processes.

Manufacturing Process

Another challenge in designing flexible circuits is the manufacturing process itself. Because flexible circuits are designed to bend and flex, they require specialized manufacturing processes that are different from those used for traditional rigid PCBs.

For example, the conductive traces need to be printed or etched onto the substrate in a way that allows for flexing without breaking or losing their electrical properties. This requires specialized equipment and processes that can be more complex and expensive than those used for rigid PCBs.

Connector Design

Connector design is another important consideration in flexible circuit design. Because flexible circuits are designed to bend and flex, the connectors need to be able to accommodate this movement without losing their electrical connection.

This requires specialized connector designs that are different from those used for traditional rigid PCBs. In addition, the connectors need to be able to withstand the stresses and strains of repeated flexing without breaking or losing their electrical properties.

EMI/EMC Considerations

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are important considerations in flexible circuit design. Because flexible circuits are often used in close proximity to other electronic components, they can be susceptible to EMI and EMC issues.

To mitigate these issues, designers need to carefully consider the layout and routing of the conductive traces, as well as the use of shielding and filtering components. In addition, the materials used in the substrate and cover lay need to be selected to minimize EMI and EMC issues.

Future of Flexible Circuitry

The future of flexible circuitry looks bright, with many exciting developments on the horizon. Some of the most promising areas of research and development include:

Stretchable Electronics

One of the most exciting areas of research in flexible circuitry is the development of stretchable electronics. These are circuits that can not only bend and flex but also stretch and deform without losing their electrical properties.

Stretchable electronics have the potential to revolutionize a wide range of applications, from wearable devices to medical implants. For example, stretchable circuits could be used to create “electronic skin” that can conform to the shape of the body and monitor various physiological parameters, such as heart rate and blood pressure.

3D Printing

Another promising area of research in flexible circuitry is the use of 3D printing technology. 3D printing allows for the rapid prototyping and manufacturing of complex structures, including flexible circuits.

With 3D printing, designers can create flexible circuits with intricate geometries and embedded components that would be difficult or impossible to manufacture using traditional methods. This could lead to the development of new types of flexible circuits with enhanced functionality and performance.

Biodegradable Electronics

Finally, there is growing interest in the development of biodegradable electronics, including flexible circuits. These are circuits that are designed to break down and decompose in the environment after they have served their purpose.

Biodegradable electronics have the potential to reduce electronic waste and minimize the environmental impact of modern electronics. They could also enable the development of new types of medical implants and environmental sensors that can safely degrade in the body or environment.

Frequently Asked Questions (FAQ)

What is the difference between flexible circuits and rigid PCBs?

Flexible circuits are designed to bend and flex without breaking or losing their electrical properties, while rigid PCBs are designed to be stiff and rigid. Flexible circuits are typically made of thin, flexible substrates, while rigid PCBs are made of thicker, more rigid materials such as FR-4.

What are the advantages of using flexible circuits?

The main advantages of using flexible circuits include space savings, weight savings, improved reliability, enhanced design freedom, and cost savings. Flexible circuits can conform to the shape of the device, reducing the overall size and weight of the system. They are also less susceptible to damage from vibration and shock, and can be designed with redundant traces and connections to improve reliability. Finally, flexible circuits can often be manufactured more efficiently and at lower cost than traditional rigid PCBs.

What are some common applications of flexible circuits?

Flexible circuits are used in a wide range of applications, from consumer electronics to medical devices to aerospace and defense systems. Some common applications include smartphones, wearable devices, hearing aids, pacemakers, cochlear implants, dashboard displays, infotainment systems, satellites, and spacecraft.

What are some of the challenges in designing flexible circuits?

Some of the main challenges in designing flexible circuits include material selection, manufacturing process, connector design, and EMI/EMC considerations. Designers need to carefully select materials that are flexible, durable, and compatible with the manufacturing process and intended application. They also need to consider specialized manufacturing processes and connector designs that can accommodate the flexing and bending of the circuit. Finally, they need to carefully consider the layout and routing of the conductive traces to minimize EMI and EMC issues.

What does the future hold for flexible circuitry?

The future of flexible circuitry looks bright, with many exciting developments on the horizon. Some of the most promising areas of research and development include stretchable electronics, 3D printing, and biodegradable electronics. These technologies have the potential to revolutionize a wide range of applications, from wearable devices to medical implants to environmental sensors.

Conclusion

Flexible circuitry is a technology that has revolutionized the electronics industry, enabling the development of smaller, lighter, and more complex systems. With its unique ability to bend and flex without breaking or losing its electrical properties, flexible circuitry has found use in a wide range of applications, from consumer electronics to medical devices to aerospace and defense systems.

While there are challenges and limitations to designing and manufacturing flexible circuits, the advantages they offer in terms of space savings, weight savings, reliability, and design freedom make them an essential component in many modern electronic devices.

As research and development in this field continue to advance, we can expect to see even more exciting developments in the future, from stretchable electronics to 3D printed circuits to biodegradable electronics. These technologies have the potential to transform the way we design and manufacture electronic devices, enabling new types of applications and solutions that were once thought impossible.

| Advantage | Description |

|---|---|

| Space Savings | Flexible circuits can bend and conform to the shape of the device, reducing the overall size and space required. |

| Weight Savings | The substrate material used in flexible circuits is much thinner and lighter than the FR-4 material used in rigid PCBs, resulting in significant weight savings. |

| Improved Reliability | Flexible circuits are less susceptible to damage from vibration and shock, and can be designed with redundant traces and connections to improve overall reliability. |

| Enhanced Design Freedom | Flexible circuits offer more flexibility in terms of component placement and routing, enabling more efficient and complex designs. |

| Cost Savings | The manufacturing process for flexible circuits is often simpler and more automated than for rigid PCBs, leading to reduced assembly time and costs. |

In conclusion, flexible circuitry is a technology that has already had a significant impact on the electronics industry, and will continue to shape the future of electronic devices. As designers and manufacturers continue to push the boundaries of what is possible with this technology, we can expect to see even more innovative and exciting applications in the years to come.

Leave a Reply