What is ESD?

ESD is the sudden flow of electricity between two objects with different electrical potentials. It can occur when an electrically charged object, such as a person or a tool, comes into contact with an electrically sensitive object, such as an electronic component or device.

ESD can generate high voltages and currents that can cause permanent damage to electronic components, leading to reduced performance, reliability issues, or complete failure. In some cases, ESD damage may not be immediately apparent, but it can manifest later as latent defects or intermittent failures.

Common Sources of ESD

There are several common sources of ESD in the workplace, including:

-

Human body: The human body can accumulate significant electrical charges through triboelectric charging, which occurs when two materials with different electrical properties come into contact and then separate.

-

Clothing: Synthetic clothing materials, such as polyester and nylon, can generate and accumulate static charges.

-

Workstations: Workstations and surfaces made of non-conductive materials, such as plastic or wood, can accumulate static charges.

-

Tools and equipment: Non-conductive tools and equipment, such as plastic trays or containers, can generate and accumulate static charges.

-

Packaging materials: Non-conductive packaging materials, such as styrofoam or plastic bubble wrap, can generate and accumulate static charges.

ESD Protection Methods

To create an anti-static environment and minimize the risk of ESD damage, several protection methods can be employed. These methods include the use of ESD protection products, grounding techniques, and proper handling procedures.

ESD Protection Products

ESD protection products are designed to dissipate or neutralize static charges, preventing the buildup and transfer of electrical charges. Some common ESD protection products include:

-

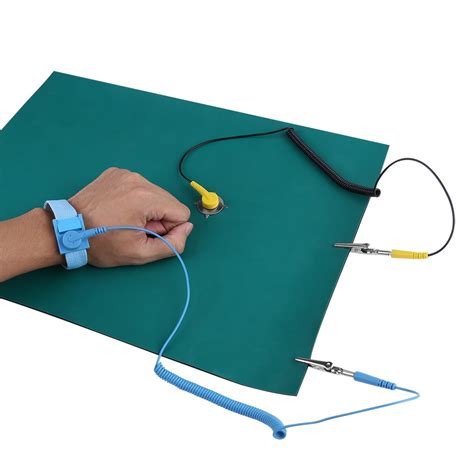

ESD mats: ESD mats are conductive or dissipative surfaces that are placed on workstations or floors to provide a safe and stable ground for personnel and equipment.

-

ESD wrist straps: ESD wrist straps are conductive bands that are worn by personnel to provide a continuous electrical connection between the person and ground, preventing the buildup of static charges.

-

ESD footwear: ESD footwear, such as conductive or dissipative shoes or heel grounders, provide a continuous electrical connection between the person and the ESD flooring.

-

ESD clothing: ESD clothing, such as lab coats or smocks, are made of conductive or dissipative materials that prevent the buildup and accumulation of static charges on the body.

-

ESD packaging: ESD packaging materials, such as conductive or dissipative bags, boxes, and containers, provide shielding and protection for sensitive electronic components during storage and transportation.

Grounding Techniques

Grounding is the process of creating an electrical connection between an object and the earth or a common reference point. Grounding techniques are used to dissipate static charges and prevent the buildup of electrical potentials. Some common grounding techniques include:

-

Equipment grounding: All conductive workstations, tools, and equipment should be properly grounded to a common reference point, such as an ESD ground.

-

Personnel grounding: Personnel should be continuously grounded using ESD wrist straps or ESD footwear when handling sensitive electronic components.

-

Bonding: Bonding is the process of connecting two or more conductive objects together to minimize the difference in electrical potential between them.

Proper Handling Procedures

In addition to using ESD protection products and grounding techniques, proper handling procedures should be followed to minimize the risk of ESD damage. Some key handling procedures include:

-

Handling components by their edges: When handling sensitive electronic components, always hold them by their edges or leads, avoiding contact with the package or pins.

-

Using ESD-safe tools: Use ESD-safe tools, such as conductive or dissipative tweezers or vacuums, to handle and manipulate sensitive components.

-

Minimizing movement: Minimize unnecessary movement or friction when handling sensitive components, as this can generate static charges.

-

Storing components in ESD packaging: When not in use, store sensitive electronic components in ESD-safe packaging to provide shielding and protection from static charges.

ESD Training and Awareness

To ensure the effectiveness of ESD protection measures, it is essential to provide proper training and raise awareness among personnel working with sensitive electronic components. ESD training should cover the following topics:

- Understanding ESD and its effects on electronic components

- Identifying common sources of ESD in the workplace

- Proper use and maintenance of ESD protection products

- Grounding techniques and their importance

- Proper handling procedures for sensitive electronic components

- Recognizing and reporting ESD events or damage

Regular refresher training and audits should be conducted to maintain a high level of ESD awareness and compliance.

ESD Auditing and Monitoring

To maintain an effective ESD protection program, regular auditing and monitoring should be performed. ESD audits should assess the following areas:

- Proper use and maintenance of ESD protection products

- Grounding continuity and effectiveness

- Compliance with handling procedures

- Condition and functionality of ESD-safe tools and equipment

- Effectiveness of ESD training and awareness programs

ESD monitoring can be performed using specialized equipment, such as static field meters or charge plate monitors, to measure the effectiveness of ESD protection measures and identify potential issues.

Frequently Asked Questions (FAQ)

1. What is the difference between conductive and dissipative materials?

Conductive materials, such as metals, have a low electrical resistance and allow the free flow of electrical charges. Dissipative materials, such as certain plastics or rubber compounds, have a higher electrical resistance and allow a controlled discharge of electrical charges.

2. How often should ESD wrist straps be tested?

ESD wrist straps should be tested before each use to ensure they are functioning properly. Most ESD wrist straps have built-in resistors that can be checked using a wrist strap tester.

3. Can ESD damage occur without visible or audible signs?

Yes, ESD damage can occur without any visible or audible signs. In some cases, the damage may be latent or may manifest as intermittent failures later on.

4. What is the recommended humidity level for an ESD-safe environment?

The recommended humidity level for an ESD-safe environment is between 30% and 70% relative humidity. Low humidity levels can increase the risk of static charge buildup, while high humidity levels can lead to corrosion or other issues.

5. How can I test the effectiveness of my ESD protection measures?

The effectiveness of ESD protection measures can be tested using specialized equipment, such as static field meters or charge plate monitors. Regular audits and monitoring can also help identify potential issues or areas for improvement.

Conclusion

Creating an anti-static environment is essential for protecting sensitive electronic components and devices from the damaging effects of ESD. By implementing a comprehensive ESD protection program that includes the use of ESD protection products, grounding techniques, proper handling procedures, and regular training and auditing, organizations can minimize the risk of ESD damage and ensure the reliability and performance of their electronic products.

As technology continues to advance and electronic components become increasingly sensitive to ESD, the importance of effective ESD protection will only continue to grow. By staying up-to-date with the latest ESD protection methods and best practices, organizations can stay ahead of the curve and maintain a competitive edge in their respective industries.

| ESD Protection Method | Description |

|---|---|

| ESD Mats | Conductive or dissipative surfaces placed on workstations or floors |

| ESD Wrist Straps | Conductive bands worn by personnel to provide a continuous ground connection |

| ESD Footwear | Conductive or dissipative shoes or heel grounders worn by personnel |

| ESD Clothing | Lab coats or smocks made of conductive or dissipative materials |

| ESD Packaging | Conductive or dissipative bags, boxes, and containers for storage and transportation |

| Grounding Technique | Description |

|---|---|

| Equipment Grounding | Connecting conductive workstations, tools, and equipment to a common ground |

| Personnel Grounding | Continuously grounding personnel using ESD wrist straps or ESD footwear |

| Bonding | Connecting two or more conductive objects together to minimize electrical potential differences |

By implementing these ESD protection methods and grounding techniques, along with proper handling procedures and regular training and auditing, organizations can create an effective anti-static environment that minimizes the risk of ESD damage to sensitive electronic components and devices.

Leave a Reply