Introduction to ESC Circuits

Electronic Speed Controller (ESC) circuits are essential components in various applications, such as drones, RC cars, and robotics. They play a crucial role in controlling the speed and direction of brushless DC motors, ensuring smooth and precise operation. In this comprehensive guide, we will dive deep into the world of ESC circuits, covering their fundamentals, types, selection criteria, and how to set them up for optimal performance.

What are ESC Circuits?

ESC circuits are electronic devices that regulate the power supplied to brushless DC motors based on the input signals received from the user or a control system. They act as intermediaries between the power source (usually a battery) and the motor, allowing for precise speed and direction control. ESCs convert DC power into three-phase AC power, which is required by brushless motors to operate efficiently.

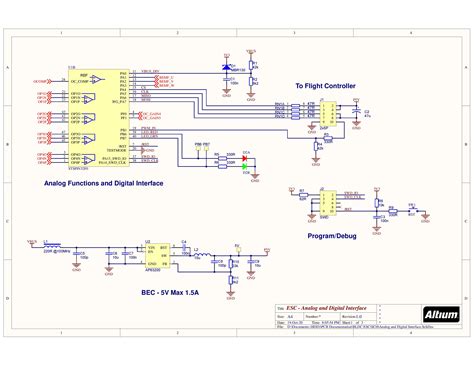

Key Components of an ESC Circuit

An ESC circuit consists of several essential components that work together to control the motor:

- Microcontroller: The brain of the ESC, responsible for processing input signals and generating the appropriate output signals to control the motor.

- MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) Bridge: A set of transistors that switch the current flow to the motor windings, creating the rotating magnetic field necessary for motor operation.

- BEC (Battery Elimination Circuit): An integrated voltage regulator that provides a stable power supply to the receiver and servos, eliminating the need for a separate battery.

- Capacitors: Used for filtering and smoothing the power supply, reducing noise and improving overall stability.

- Connectors: Provide a means to connect the ESC to the battery, motor, and receiver.

Types of ESC Circuits

There are two main types of ESC circuits: brushed and brushless. While they serve the same purpose of controlling motor speed and direction, they differ in their design and compatibility with specific motor types.

Brushed ESC Circuits

Brushed ESC circuits are designed to work with brushed DC motors, which have physical brushes that make contact with the commutator to control the current flow. These ESCs are generally simpler and less expensive than their brushless counterparts. They are commonly used in entry-level RC vehicles and simpler robotics applications.

Brushless ESC Circuits

Brushless ESC circuits are more advanced and are specifically designed to work with brushless DC motors. These motors do not have physical brushes; instead, they rely on the ESC to control the current flow to the motor windings electronically. Brushless ESCs offer higher efficiency, better performance, and longer lifespan compared to brushed ESCs. They are widely used in high-performance applications, such as drones, advanced RC vehicles, and industrial robotics.

Choosing the Right ESC Circuit

Selecting the appropriate ESC circuit for your application is crucial for optimal performance and reliability. Consider the following factors when choosing an ESC:

Motor Compatibility

Ensure that the ESC is compatible with the type of motor you are using (brushed or brushless). Pay attention to the motor’s specifications, such as the maximum current rating and the number of poles, to select an ESC that can handle the motor’s requirements.

Current Rating

Choose an ESC with a current rating that exceeds the maximum current draw of your motor. It is recommended to have a safety margin of at least 20% to account for transient current spikes and ensure reliable operation.

Voltage Range

Make sure the ESC’s voltage range is compatible with your power source (battery). Most ESCs have a specified voltage range, and operating outside this range can lead to poor performance or damage to the ESC.

Programming and Calibration Features

Consider an ESC with programmable settings and calibration features, especially if you require fine-tuning the performance for specific applications. These features allow you to adjust parameters such as throttle range, brake strength, timing, and low voltage cutoff.

Size and Weight

For weight-sensitive applications like drones, opt for compact and lightweight ESCs to minimize the overall system weight and improve flight performance. In other applications, size and weight may be less critical, allowing for more flexibility in ESC selection.

Brand and Quality

Invest in ESCs from reputable brands known for their quality and reliability. Read reviews and seek recommendations from experienced users in your application area to make an informed decision.

Setting Up and Configuring ESC Circuits

Proper setup and configuration of your ESC circuit are essential for optimal performance and safe operation. Follow these steps to get your ESC up and running:

1. Soldering and Connections

- Solder the motor wires to the ESC’s motor output pads, ensuring correct polarity and secure connections.

- Connect the ESC’s battery input to your power source, making sure to observe the correct polarity.

- Connect the ESC’s signal input to the receiver or flight controller, following the manufacturer’s instructions for the specific channel and protocol.

2. ESC Calibration

Most ESCs require calibration to ensure proper throttle range and response. The calibration process typically involves the following steps:

- Turn on the transmitter and set the throttle stick to the maximum position.

- Connect the battery to the ESC (this may require a specific sequence, such as plugging in the battery while holding a button on the ESC).

- Wait for the ESC to emit a specific number of beeps, indicating that it has registered the maximum throttle position.

- Move the throttle stick to the minimum position and wait for the ESC to emit another series of beeps, confirming the minimum throttle position.

- The ESC is now calibrated and ready for use.

3. Programming and Fine-Tuning

If your ESC supports programmable settings, you can use a programming card or a dedicated software tool to adjust various parameters, such as:

- Brake strength

- Timing advance

- Low voltage cutoff

- Throttle curve

- Motor rotation direction

Refer to your ESC’s manual for specific instructions on accessing and modifying these settings.

Troubleshooting Common ESC Issues

Despite proper setup and configuration, you may encounter issues with your ESC circuit. Here are some common problems and their potential solutions:

Motor Not Responding

- Check the connections between the ESC, motor, and receiver to ensure they are secure and free from damage.

- Verify that the ESC is properly calibrated and that the transmitter is set up correctly.

- Ensure that the battery is fully charged and capable of delivering the required current.

Erratic Motor Behavior

- Check for loose connections or damaged wires that may cause intermittent signal or power disruptions.

- Ensure that the ESC’s programming settings are appropriate for your application and motor specifications.

- Verify that the ESC and motor are adequately cooled and not experiencing thermal throttling.

ESC Overheating

- Ensure that the ESC’s current rating is sufficient for your motor’s maximum current draw.

- Provide adequate cooling for the ESC, using heatsinks or active cooling solutions if necessary.

- Check for any obstructions or restrictions in the ESC’s airflow path.

Reduced Flight Time or Performance

- Verify that the battery is in good condition and capable of delivering the required capacity and discharge rate.

- Ensure that the ESC’s low voltage cutoff setting is appropriate for your battery chemistry and cell count.

- Check for any mechanical issues, such as binding or friction, that may be placing additional load on the motor and ESC.

If the issue persists, consult the ESC manufacturer’s support resources or seek assistance from experienced users in your application area.

Frequently Asked Questions (FAQs)

-

Can I use a brushless ESC with a brushed motor?

No, brushless ESCs are designed specifically for brushless motors and are not compatible with brushed motors. Using a brushless ESC with a brushed motor can damage both the ESC and the motor. -

What happens if I use an ESC with a lower current rating than my motor?

Using an ESC with a lower current rating than your motor’s maximum current draw can lead to overheating, reduced performance, and potentially permanent damage to the ESC. Always choose an ESC with a current rating that exceeds your motor’s requirements. -

Can I connect multiple motors to a single ESC?

No, each motor requires its own dedicated ESC. Connecting multiple motors to a single ESC can cause excessive current draw, leading to ESC failure and potential damage to the motors. -

How do I know if my ESC is compatible with my receiver or flight controller?

Ensure that the ESC supports the same communication protocol (e.g., PWM, OneShot, DShot) as your receiver or flight controller. Refer to the ESC and receiver/flight controller documentation for compatibility information. -

What should I do if my ESC emits smoke or a burning smell?

If your ESC emits smoke or a burning smell, immediately disconnect the battery and discontinue use. This indicates a serious issue, such as a short circuit or component failure. Contact the ESC manufacturer for support and avoid using the ESC until the issue is resolved.

Conclusion

ESC circuits are vital components in various applications, enabling precise speed and direction control of brushless DC motors. By understanding the fundamentals of ESC circuits, selecting the appropriate type and specifications for your application, and following proper setup and configuration procedures, you can ensure optimal performance and reliability.

Remember to choose ESCs from reputable brands, consider factors such as current rating, voltage range, and programmability, and take the time to calibrate and fine-tune your ESC for your specific requirements. Regular maintenance, monitoring, and troubleshooting will help you identify and resolve any issues that may arise during operation.

With this comprehensive guide, you now have the knowledge and tools to confidently work with ESC circuits in your projects. Whether you are building drones, RC vehicles, or robotics systems, mastering ESC circuits will undoubtedly enhance your creations’ performance and capabilities.

Leave a Reply