Introduction to PCB Data Files

When placing an order for a printed circuit board (PCB), it is essential to provide the manufacturer with the necessary data files. These files contain critical information about your PCB design, including the layout, components, and specifications. Uploading the correct data files ensures that your PCB will be fabricated according to your requirements, minimizing the risk of errors and delays.

In this article, we will explore the various data files you should include when uploading your PCB order, with a focus on stencil-mate files. We will also discuss the importance of each file type and provide tips for ensuring that your data is accurate and complete.

Types of PCB Data Files

There are several types of data files that you may need to provide when ordering a PCB. The specific files required may vary depending on the manufacturer and the complexity of your design. However, the following are some of the most common data files used in PCB fabrication:

1. Gerber Files

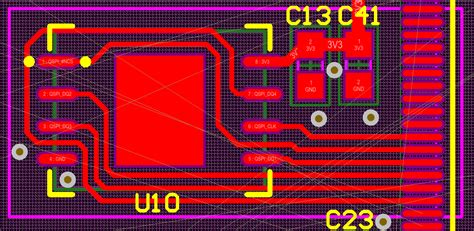

Gerber files are the most essential data files for PCB fabrication. They contain information about the copper layers, solder mask, silkscreen, and drill holes of your PCB. Gerber files are named according to their function, such as:

.GTL(Top Copper Layer).GBL(Bottom Copper Layer).GTS(Top Solder Mask).GBS(Bottom Solder Mask).GTO(Top Silkscreen).GBO(Bottom Silkscreen).TXT(Drill File)

It is crucial to ensure that your Gerber files are generated correctly and include all the necessary layers. Most PCB design software can export Gerber files, but it is essential to double-check the settings to avoid any errors.

2. Drill Files

Drill files contain information about the location, size, and type of holes to be drilled in your PCB. There are two main types of drill files:

.DRL(Drill File).PHO(Plated Hole File)

The .DRL file specifies the location and size of all the holes in your PCB, while the .PHO file indicates which holes should be plated. It is important to ensure that your drill files are accurate and complete to avoid any issues during fabrication.

3. Stencil-Mate Files

Stencil-mate files are used for creating solder paste stencils, which are essential for surface mount technology (SMT) assembly. These files contain information about the solder paste apertures and their locations on the PCB. The most common stencil-mate file formats are:

.GBP(Gerber Paste File).GTP(Gerber Top Paste).GBR(Gerber Bottom Paste)

Stencil-mate files should be generated based on your PCB design and the specific requirements of your SMT assembly process. It is essential to ensure that the aperture sizes and locations are correct to avoid any issues during the solder paste application.

4. Pick and Place Files

Pick and place files, also known as centroid files, contain information about the location and orientation of surface mount components on your PCB. These files are used by automated pick and place machines to accurately place components during the SMT assembly process. Common pick and place file formats include:

.CSV(Comma Separated Values).TXT(Text File).XLS(Excel Spreadsheet)

It is crucial to ensure that your pick and place files are accurate and include all the necessary components. Any errors in these files can lead to incorrect component placement and potential functionality issues.

5. Bill of Materials (BOM)

A bill of materials (BOM) is a comprehensive list of all the components used in your PCB design. It typically includes information such as the part number, quantity, description, and manufacturer for each component. The BOM is essential for ensuring that the correct components are ordered and used during the assembly process.

When creating a BOM, it is important to use a consistent format and include all the necessary information. Many PCB design software tools can generate a BOM automatically based on your design, but it is always a good idea to review and verify the information before submitting it to your manufacturer.

Importance of Accurate PCB Data Files

Providing accurate and complete PCB data files is essential for ensuring the success of your PCB fabrication and assembly. Here are some reasons why accurate data files are so important:

-

Avoiding Errors: Inaccurate or incomplete data files can lead to errors during the fabrication process, such as incorrect layer alignment, wrong hole sizes, or missing components. These errors can result in delays, additional costs, and even non-functional boards.

-

Ensuring Functionality: Accurate data files are essential for ensuring that your PCB functions as intended. Any discrepancies between your design and the manufactured board can lead to performance issues or complete failure of your device.

-

Streamlining Communication: Clear and comprehensive data files help streamline communication between you and your PCB manufacturer. By providing all the necessary information upfront, you can minimize the need for back-and-forth communication and clarify any potential issues before fabrication begins.

-

Saving Time and Money: Accurate data files can help save time and money by reducing the likelihood of errors and rework. By getting your PCB right the first time, you can avoid costly delays and additional fabrication runs.

Tips for Preparing PCB Data Files

To ensure that your PCB data files are accurate and complete, consider the following tips:

-

Use a Consistent Naming Convention: Use a clear and consistent naming convention for your data files to avoid confusion and ensure that all the necessary files are included.

-

Double-Check Your Files: Before submitting your data files, take the time to double-check them for accuracy and completeness. Verify that all the necessary layers and components are included and that the dimensions and specifications match your design.

-

Use a Gerber Viewer: Use a Gerber viewer to visually inspect your Gerber files before submitting them. This can help you catch any errors or discrepancies that may not be apparent in the design software.

-

Communicate with Your Manufacturer: If you have any questions or concerns about the data files required for your PCB order, don’t hesitate to communicate with your manufacturer. They can provide guidance and support to ensure that your files are prepared correctly.

-

Keep a Backup: Always keep a backup of your PCB data files, including your design files and any revisions. This can help you quickly recover in case of data loss or if you need to refer back to an earlier version of your design.

Frequently Asked Questions (FAQ)

-

What are the most critical data files for PCB fabrication?

The most critical data files for PCB fabrication are the Gerber files, which contain information about the copper layers, solder mask, silkscreen, and drill holes. Without accurate and complete Gerber files, it is impossible to fabricate a functional PCB. -

Can I submit my PCB design files directly to the manufacturer?

While some manufacturers may accept PCB design files directly, it is generally recommended to generate and submit the specific data files required for fabrication, such as Gerber files and drill files. This ensures that the manufacturer has all the necessary information in a standardized format. -

What happens if I submit incomplete or inaccurate data files?

Submitting incomplete or inaccurate data files can lead to errors in the fabrication process, resulting in delays, additional costs, and potentially non-functional boards. In some cases, the manufacturer may need to contact you for clarification or request updated files, which can further extend the lead time. -

How do I generate stencil-mate files for my PCB?

Stencil-mate files can typically be generated using your PCB design software. Look for options related to solder paste or stencil generation, and ensure that the settings match your specific requirements for solder paste application. If you are unsure about how to generate stencil-mate files, consult your design software documentation or contact your manufacturer for guidance. -

Can I use different file formats for my PCB data files?

While some manufacturers may accept different file formats, it is generally recommended to use the standard formats for each type of data file, such as Gerber files for copper layers and drill files for hole information. Using standard file formats ensures compatibility and reduces the risk of errors in the fabrication process. If you have specific file format requirements, it is best to discuss them with your manufacturer beforehand.

Conclusion

Uploading accurate and complete PCB data files is essential for ensuring the success of your PCB fabrication and assembly. By providing the necessary Gerber files, drill files, stencil-mate files, pick and place files, and bill of materials, you can help your manufacturer produce a high-quality PCB that meets your specifications and functions as intended.

Remember to use a consistent naming convention, double-check your files for accuracy, and communicate with your manufacturer if you have any questions or concerns. By following these best practices and working closely with your PCB manufacturer, you can streamline the fabrication process and bring your electronic designs to life.

Leave a Reply