What is PCB Assembly?

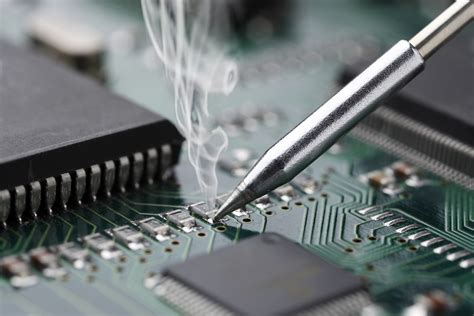

PCB assembly is the process of soldering or mounting electronic components onto a printed circuit board (PCB). The PCB serves as the foundation for the electrical interconnections between components. PCB assembly transforms a bare board into a functional electronic device.

The PCB assembly process involves several steps:

-

Solder Paste Application: Solder paste, a mixture of tiny solder particles suspended in flux, is precisely applied onto the PCB’s pads using a stencil or solder paste printer.

-

Component Placement: Surface mount devices (SMDs) and through-hole components are placed onto their designated locations on the PCB. High-speed pick-and-place machines automate this process for SMDs.

-

Reflow Soldering: The PCB with components passes through a reflow oven. The solder paste melts in a controlled heating process, forming permanent electrical connections between the components and the PCB pads.

-

Inspection and Testing: Assembled PCBs undergo automated optical inspection (AOI) and electrical testing to identify any defects or malfunctions before proceeding to the next stage.

Why China is a Global Leader in PCB Assembly

China has emerged as a global powerhouse in PCB assembly due to several factors:

Cost Advantage

China’s lower labor costs and economies of scale enable PCB assembly providers to offer competitive pricing. This cost advantage attracts electronics manufacturers worldwide to outsource their PCB assembly to China.

Extensive Supply Chain

China has a well-established and comprehensive supply chain for electronic components and PCB materials. The proximity and availability of suppliers facilitate efficient procurement and shorter lead times.

Skilled Workforce

China has a large pool of skilled workers experienced in PCB assembly. Technical schools and vocational training programs ensure a steady supply of qualified personnel to meet the industry’s demands.

Advanced Infrastructure

China has invested heavily in developing advanced manufacturing infrastructure, including state-of-the-art PCB assembly facilities equipped with automated equipment and technology.

Government Support

The Chinese government has implemented policies and incentives to support the growth of the electronics industry, including tax breaks, subsidies, and infrastructure development.

Key Considerations for PCB Assembly in China

When outsourcing PCB assembly to China, there are several critical aspects to consider:

Quality Control

Ensuring consistent quality is paramount. Look for PCB assembly providers with robust quality management systems, such as ISO 9001 certification. Request information about their testing and inspection processes, including AOI, X-ray inspection, and functional testing.

Communication and Language

Clear communication is essential for successful PCB assembly outsourcing. Choose a provider with proficient English-speaking staff or dedicated project managers to facilitate effective communication. Establish well-defined communication channels and protocols.

Intellectual Property (IP) Protection

Protect your intellectual property when outsourcing PCB assembly. Implement non-disclosure agreements (NDAs) and conduct due diligence on the provider’s IP protection measures. Consider working with providers that have a track record of respecting and safeguarding client IP.

Delivery and Logistics

Discuss delivery terms, lead times, and logistics arrangements with potential providers. Understand their shipping options, customs clearance procedures, and any additional costs involved. Consider the proximity of the provider to major shipping hubs and airports.

Certifications and Standards

Ensure that the PCB assembly provider complies with relevant industry standards and certifications, such as IPC (Association Connecting Electronics Industries) standards for PCB manufacturing and assembly. Additional certifications like ISO 14001 for environmental management and IATF 16949 for automotive quality management may be required depending on your industry.

PCB Assembly Service Options in China

China offers a range of PCB assembly service options to cater to different client requirements:

| Service | Description |

|---|---|

| Turnkey Service | The provider handles the entire PCB assembly process, from component sourcing to final testing. |

| Consignment Service | The client supplies components, and the provider performs assembly and testing. |

| Partial Turnkey Service | The client supplies some components, while the provider sources the rest and performs assembly. |

Choose the service option that aligns with your supply chain strategy, component availability, and cost considerations.

Choosing the Right PCB Assembly Partner in China

Selecting the right PCB assembly partner in China is crucial for the success of your project. Consider the following factors:

-

Experience and Expertise: Look for providers with a proven track record in PCB assembly, particularly in your industry or application domain. Assess their technical capabilities and familiarity with your product requirements.

-

Manufacturing Capabilities: Evaluate the provider’s manufacturing facilities, equipment, and technology. Ensure they have the necessary capabilities to handle your PCB complexity, volume, and specific requirements (e.g., BGA placement, fine-pitch components).

-

Quality Management: Assess the provider’s quality management system, certifications, and adherence to industry standards. Inquire about their quality control processes, testing methodologies, and defect rates.

-

Scalability and Flexibility: Consider the provider’s ability to scale production based on your demand fluctuations. Assess their responsiveness to changes in design or order quantities and their flexibility in accommodating your specific needs.

-

Customer Support: Evaluate the level of customer support offered by the provider. Look for dedicated account managers, responsive communication, and proactive problem-solving approaches.

-

Reputation and References: Research the provider’s reputation in the industry. Seek references from existing clients and gather feedback on their experience, reliability, and overall satisfaction.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity (MOQ) for PCB assembly in China?

MOQs vary among PCB assembly providers in China. Some providers offer low MOQs, even as low as one piece, to cater to prototype and small-volume production. However, larger MOQs may be required for high-volume production to achieve cost efficiency. Discuss your specific requirements with potential providers to determine their MOQ policies.

2. How long does PCB assembly in China typically take?

Lead times for PCB assembly in China depend on various factors, such as PCB complexity, order quantity, and component availability. Prototype and small-volume orders can typically be completed within 1-2 weeks, while larger volume production may take several weeks. Rush services may be available for time-critical projects, but they often incur additional costs.

3. Can I supply my own components for PCB assembly in China?

Yes, many PCB assembly providers in China offer consignment services, where clients supply their own components. This option is suitable if you have existing component inventory or specific component requirements. However, ensure that you provide detailed component specifications and maintain clear communication with the provider regarding component management and handling.

4. How can I ensure the quality of PCB assembly in China?

To ensure the quality of PCB assembly in China, consider the following:

- Choose a provider with a robust quality management system and relevant certifications (e.g., ISO 9001, IPC standards).

- Clearly communicate your quality requirements and specifications to the provider.

- Request detailed information about their testing and inspection processes, including AOI, X-ray inspection, and functional testing.

- Establish quality control checkpoints and regular communication to monitor progress and address any issues promptly.

- Consider on-site visits or third-party inspections to assess the provider’s facilities and processes firsthand.

5. What are the shipping and logistics options for PCB assembly in China?

PCB assembly providers in China offer various shipping and logistics options, including:

- Air freight: Faster but more expensive option, suitable for time-sensitive deliveries.

- Sea freight: Cost-effective option for larger shipments, but with longer transit times.

- Express courier services: Ideal for smaller shipments and faster delivery times.

- Door-to-door logistics: Some providers offer end-to-end logistics services, including customs clearance and final delivery to your designated location.

Discuss your shipping requirements, urgency, and cost considerations with the provider to determine the most suitable option for your needs.

Conclusion

China PCB assembly is a critical aspect of electronics manufacturing, offering cost advantages, a skilled workforce, and advanced infrastructure. When outsourcing PCB assembly to China, consider factors such as quality control, communication, IP protection, delivery, and certifications.

Choose a PCB assembly partner that aligns with your requirements, has relevant experience and expertise, and demonstrates a commitment to quality and customer support. By carefully selecting the right provider and establishing clear communication and expectations, you can leverage the benefits of China PCB assembly for your electronic products.

Leave a Reply