ALL ABOUT FLEX PCB

-

PCB PCBA-Devices In Which Are Applied | RAYPCB

Posted by

–

Read more: PCB PCBA-Devices In Which Are Applied | RAYPCB

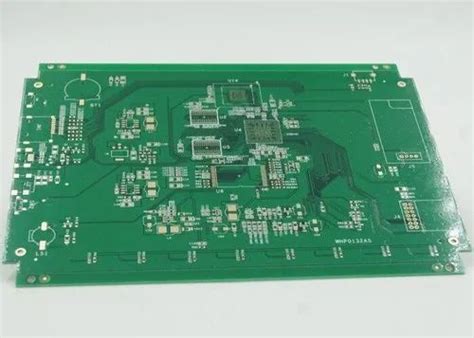

Read more: PCB PCBA-Devices In Which Are Applied | RAYPCBIntroduction to PCB and PCBA Printed Circuit Boards (PCBs) and Printed Circuit Board Assemblies (PCBAs) are essential components in a wide range of electronic devices. These boards provide a platform for mounting and interconnecting electronic components, allowing for the creation of complex circuits and systems. PCBs and PCBAs are used […]

-

Read more: A Guide to PCBA: Definition, Types, Applications, and Process

Read more: A Guide to PCBA: Definition, Types, Applications, and ProcessWhat is PCBA? PCBA stands for Printed Circuit Board Assembly, which is the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. The PCB is a flat board made of insulating materials, such as fiberglass or plastic, with conductive tracks, pads, and […]

-

PCBA Manufacturing: A Step-by-Step Guide

Posted by

–

Read more: PCBA Manufacturing: A Step-by-Step Guide

Read more: PCBA Manufacturing: A Step-by-Step GuideIntroduction to PCBA Manufacturing Printed Circuit Board Assembly (PCBA) manufacturing is a complex process that involves the assembly of electronic components onto a printed circuit board (PCB). The PCB is the backbone of every electronic device, and the quality of the PCBA determines the overall performance and reliability of the […]

-

RAYMING Is A Through Hole PCB Assembly Expert

Posted by

–

Read more: RAYMING Is A Through Hole PCB Assembly Expert

Read more: RAYMING Is A Through Hole PCB Assembly ExpertIntroduction to PCB Assembly PCB (Printed Circuit Board) assembly is the process of soldering electronic components onto a printed circuit board to create a functional electronic device. It is a crucial step in the manufacturing process of electronic products, as it determines the quality, reliability, and performance of the final […]

-

Read more: The Importance of Plated through-hole Technology in PCB Production

Read more: The Importance of Plated through-hole Technology in PCB ProductionWhat is Plated Through-Hole (PTH) Technology in PCB? Plated through-hole (PTH) technology is a crucial process in the production of printed circuit boards (PCBs). It involves creating holes in the PCB substrate and plating them with a conductive material, typically copper, to establish electrical connections between different layers of the […]

-

Read more: RAYMING: Your First Choice of Quick Turn PCB Manufacturing

Read more: RAYMING: Your First Choice of Quick Turn PCB ManufacturingIntroduction to RAYMING and Quick-Turn PCB Manufacturing RAYMING is a leading provider of quick-turn printed circuit board (PCB) manufacturing services. With state-of-the-art facilities and a team of experienced engineers, RAYMING offers fast, reliable, and high-quality PCB fabrication for prototypes and low-volume production runs. Quick-turn PCB manufacturing refers to the rapid […]

-

Rigid Flex PCB vs. Flexible PCB

Posted by

–

Read more: Rigid Flex PCB vs. Flexible PCB

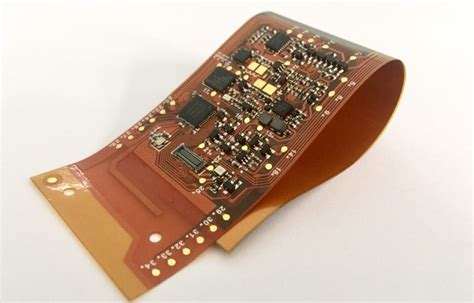

Read more: Rigid Flex PCB vs. Flexible PCBIntroduction to Rigid-Flex PCBs and Flexible PCBs Printed Circuit Boards (PCBs) have revolutionized the electronics industry by providing a reliable and efficient way to connect electronic components. As technology advances, the demand for more versatile and compact PCBs has led to the development of Rigid-Flex PCBs and Flexible PCBs. While […]

-

Read more: Should I Use Double Layer PCB or Single Layer PCB?

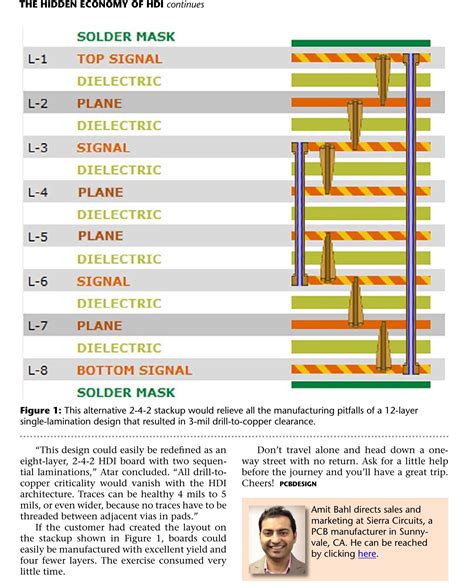

Read more: Should I Use Double Layer PCB or Single Layer PCB?Introduction to PCB Layers Printed Circuit Boards (PCBs) are essential components in modern electronics. They provide a platform for mounting and interconnecting electronic components, allowing for the creation of complex circuits. One of the key decisions in PCB design is choosing between a single layer PCB and a double layer […]

-

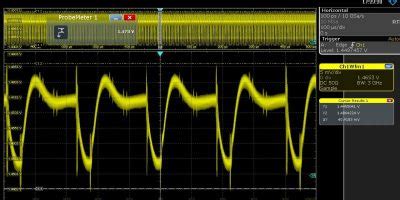

Read more: Signal and Power Integrity Fundamentals on High Speed

Read more: Signal and Power Integrity Fundamentals on High SpeedUnderstanding Signal Integrity and Power Integrity Signal integrity (SI) and power integrity (PI) are crucial aspects of high-speed electronic systems. As data rates continue to increase, ensuring the quality and reliability of signals becomes more challenging. This article will delve into the fundamentals of signal and power integrity, discussing key […]

-

Read more: What is Flexible PCB: An Introduction to Flexible Circuit Boards

Read more: What is Flexible PCB: An Introduction to Flexible Circuit BoardsWhat is a Flexible PCB? A flexible printed circuit board (PCB), also known as a flex circuit or flexible electronics, is a type of PCB that consists of a thin, flexible plastic substrate with printed circuitry. Unlike traditional Rigid PCBs, Flexible PCBs can bend, twist, and conform to various shapes, […]