ALL ABOUT FLEX PCB

-

Types of Electrical Test for PCB

Posted by

–

Read more: Types of Electrical Test for PCB

Read more: Types of Electrical Test for PCBIntroduction to PCB Electrical Tests Printed Circuit Boards (PCBs) are essential components in modern electronic devices. To ensure their reliability and performance, various electrical tests are conducted during the manufacturing process. These tests help identify defects, verify functionality, and ensure compliance with industry standards. In this article, we will explore […]

-

PCB Multi-layer Fabrication – Lay-up and Bond

Posted by

–

Read more: PCB Multi-layer Fabrication – Lay-up and Bond

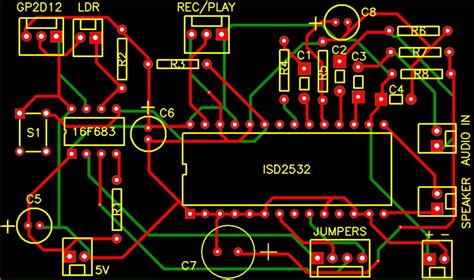

Read more: PCB Multi-layer Fabrication – Lay-up and BondIntroduction to PCB Lay-up PCB (Printed Circuit Board) lay-up is a crucial step in the multi-layer PCB fabrication process. It involves stacking and aligning multiple layers of the PCB, including the core, prepreg, and copper foil, to create a compact and functional circuit board. The lay-up process ensures that the […]

-

Read more: How we can guarantee the quality of your PCB Part 1

Read more: How we can guarantee the quality of your PCB Part 1Introduction to PCB Quality Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and laptops to medical equipment and aerospace systems. The quality of a PCB directly impacts the performance, reliability, and longevity of the electronic device it powers. […]

-

PCB Connector Types – What You Need To Know

Posted by

–

Read more: PCB Connector Types – What You Need To Know

Read more: PCB Connector Types – What You Need To KnowTypes of PCB Connectors 1. Header Connectors Header connectors, also known as pin headers or board-to-board connectors, are commonly used for connecting PCBs to other PCBs or to ribbon cables. They consist of a row of male pins that mate with corresponding female sockets. Characteristics of Header Connectors Available in […]

-

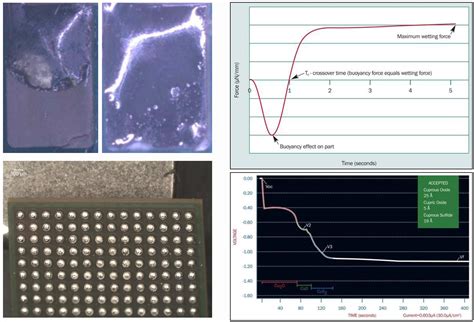

Read more: Solderability Test: Understanding PCB Solderability Testing

Read more: Solderability Test: Understanding PCB Solderability TestingWhat is Solderability Testing? Solderability testing is a process used to evaluate the ability of electronic components and printed circuit boards (PCBs) to be soldered effectively. It assesses the wettability and adhesion properties of the surfaces to be soldered, ensuring reliable electrical connections and mechanical strength. Solderability testing is crucial […]

-

Read more: High Tg PCB Manufacturer With RF4 PCBs of Any Tg Available

Read more: High Tg PCB Manufacturer With RF4 PCBs of Any Tg AvailableIntroduction to High-Tg PCBs High-Tg PCBs, also known as high glass transition temperature printed Circuit Boards, are a type of PCB that can withstand higher temperatures compared to standard PCBs. The glass transition temperature (Tg) refers to the temperature at which the material transitions from a rigid, glassy state to […]

-

When should I choose 2 layer PCB or 4 layer PCB

Posted by

–

Read more: When should I choose 2 layer PCB or 4 layer PCB

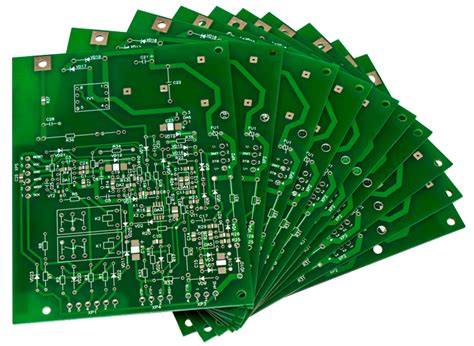

Read more: When should I choose 2 layer PCB or 4 layer PCBUnderstanding PCB Layers Before diving into the comparison between 2 layer and 4 layer PCBs, let’s first understand what PCB layers are and their significance. What are PCB Layers? PCB layers refer to the number of conductive copper layers within a PCB. These layers are used to route electrical signals […]

-

The Final Inspection of PCB Assembly

Posted by

–

Read more: The Final Inspection of PCB Assembly

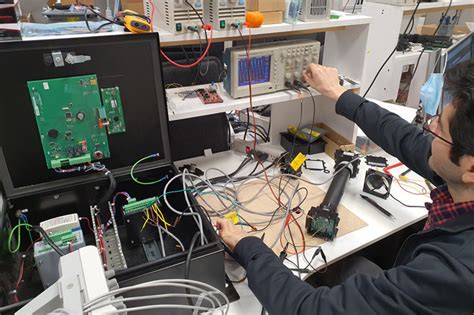

Read more: The Final Inspection of PCB AssemblyIntroduction to PCB inspection Printed Circuit Board (PCB) assembly is a complex process involving many steps, from component placement to soldering. To ensure the quality and reliability of the final product, a thorough inspection is crucial. This final inspection is the last line of defense against any defects or issues […]

-

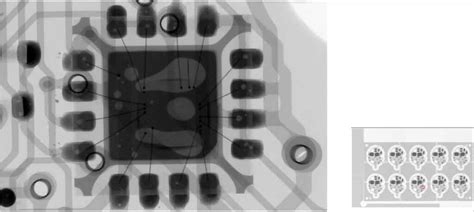

What is x-ray inspection in PCB?

Posted by

–

Read more: What is x-ray inspection in PCB?

Read more: What is x-ray inspection in PCB?What is a Printed Circuit Board (PCB)? A printed circuit board, or PCB, is a fundamental component in modern electronic devices. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, […]

-

Read more: The Most Detailed Introduction AOI Inspection(Latest)

Read more: The Most Detailed Introduction AOI Inspection(Latest)What is AOI Inspection? AOI (Automated Optical Inspection) is a critical process in the manufacturing of printed circuit boards (PCBs) and other electronic components. It involves using specialized cameras and image processing software to automatically inspect the quality of manufactured products for defects, such as missing components, incorrect component placement, […]