ALL ABOUT FLEX PCB

-

Read more: Different Types of PCB Substrate Material for Your Project

Read more: Different Types of PCB Substrate Material for Your ProjectCommon PCB Substrate Materials There are several common substrate materials used in PCB manufacturing, each with its own set of properties and advantages. The following table summarizes the most widely used PCB substrate materials: Material Description Key Properties FR-4 Glass-reinforced epoxy laminate Good electrical insulation, moderate thermal stability, cost-effective High […]

-

Electronic Manufacturing Services

Posted by

–

Read more: Electronic Manufacturing Services

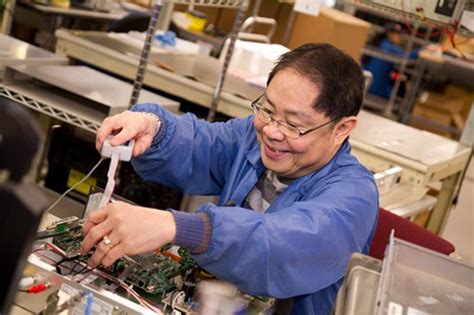

Read more: Electronic Manufacturing ServicesWhat is Electronic Manufacturing Services (EMS)? Electronic Manufacturing Services (EMS) is a service provided by companies that design, manufacture, test, distribute, and repair electronic components and assemblies for original equipment manufacturers (OEMs). EMS companies provide a wide range of services, including: Product design and engineering Prototyping and testing Supply chain […]

-

Read more: What to do with Discontinued Electronic Components

Read more: What to do with Discontinued Electronic ComponentsUnderstanding Discontinued Electronics What are Discontinued Electronic Components? Discontinued electronic components are parts that are no longer being manufactured or supported by the original supplier. This can happen for a variety of reasons, such as: Technological advancements rendering the component obsolete Lack of demand for the component Changes in industry […]

-

Read more: High Power LED Lights with 100W, 200W, and Higher Power

Read more: High Power LED Lights with 100W, 200W, and Higher PowerWhat are High Power LED Lights? High power LED lights are a type of light-emitting diode (LED) technology designed to deliver exceptional brightness and efficiency. These lights typically have power ratings of 100W, 200W, and higher, making them suitable for a wide range of applications that require intense illumination. Some […]

-

6 Tips on How To Repair Printed Circuit Board

Posted by

–

Read more: 6 Tips on How To Repair Printed Circuit Board

Read more: 6 Tips on How To Repair Printed Circuit BoardUnderstanding PCB Repair PCB repair is the process of identifying and fixing issues in a printed circuit board to restore its functionality. This can involve various techniques, such as soldering, desoldering, cleaning, and replacing components. Successful PCB repair requires a combination of technical knowledge, practical skills, and the right tools. […]

-

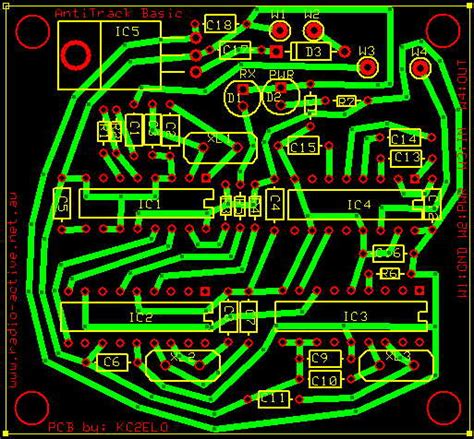

What is PCB Copper Layers

Posted by

–

Read more: What is PCB Copper Layers

Read more: What is PCB Copper LayersWhat are PCB Copper Layers? PCB copper layers are thin sheets of copper foil laminated onto the insulating substrate material of a printed circuit board. These layers act as conductive pathways for electrical signals and power distribution between various components on the board. The number of copper layers in a […]

-

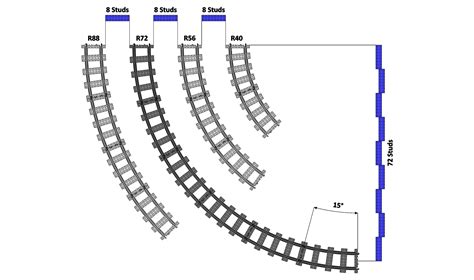

Why is track width important in PCB design?

Posted by

–

Read more: Why is track width important in PCB design?

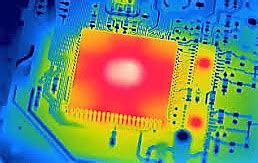

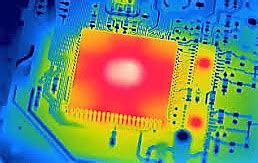

Read more: Why is track width important in PCB design?Introduction to Track width in PCB Design Track width is a crucial aspect of printed circuit board (PCB) design that significantly impacts the performance, reliability, and manufacturability of electronic devices. In PCB design, tracks are the conductive paths that carry electrical signals and power between components. The width of these […]

-

Read more: 11 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality

Read more: 11 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality1. Optimize PCB Design for Manufacturing (DFM) One of the most effective ways to cut PCB Assembly Costs is to optimize your PCB design for manufacturing (DFM). By following DFM guidelines, you can ensure that your PCB design is compatible with the manufacturing process, minimizing the risk of errors, delays, […]

-

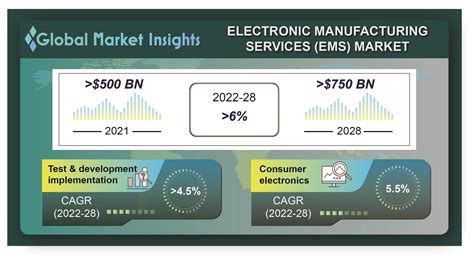

Read more: Electronic Manufacturing Services (EMS) Market Analysis & Trends 2024

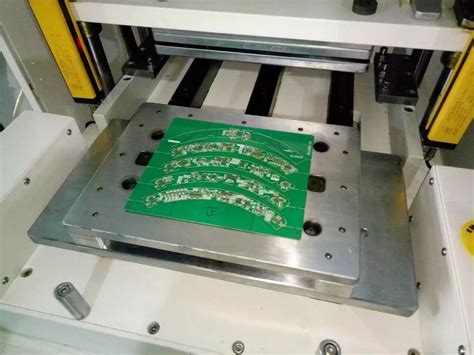

Read more: Electronic Manufacturing Services (EMS) Market Analysis & Trends 2024Overview of the EMS Market Electronic Manufacturing Services (EMS) refers to the outsourcing of electronic product manufacturing to specialized companies. These companies provide a range of services, including design, assembly, testing, and supply chain management. The EMS industry has grown significantly over the past few decades, driven by the increasing […]

-

Read more: Pay attention to some issues related to Express PCB manufacturing & assembly.

Read more: Pay attention to some issues related to Express PCB manufacturing & assembly.What is Express PCB Manufacturing? Express PCB manufacturing refers to the rapid fabrication and assembly of printed circuit boards (PCBs) within a short turnaround time. This service is essential for businesses and individuals who require quick prototyping or small-scale production of PCBs for their projects. Express PCB manufacturers utilize advanced […]