ALL ABOUT FLEX PCB

-

Read more: 12 Guides To Help You Choose The Right PCB Conformal Coating

Read more: 12 Guides To Help You Choose The Right PCB Conformal CoatingIntroduction When it comes to protecting your printed circuit boards (PCBs) from harsh environmental conditions, applying a conformal coating is one of the most effective methods. PCB Conformal Coating is a thin layer of protective material that is applied to the surface of a PCB to shield it from moisture, […]

-

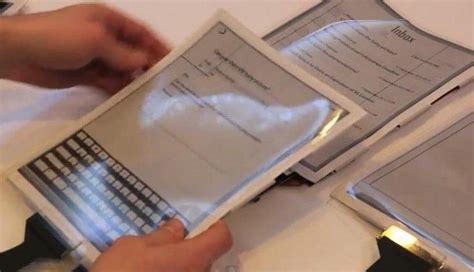

Read more: Paper Tab-Revolutionary High Tech Quick Introducing

Read more: Paper Tab-Revolutionary High Tech Quick IntroducingWhat is PaperTab? PaperTab is a revolutionary new technology that aims to replace traditional paper documents with flexible, high-resolution electronic displays. Developed by a team of researchers from Queen’s University in collaboration with Plastic Logic and Intel Labs, PaperTab combines the familiarity and ease of use of paper with the […]

-

How to make sure PCB Printing Properly

Posted by

–

Read more: How to make sure PCB Printing Properly

Read more: How to make sure PCB Printing ProperlyIntroduction to PCB Printing Printed Circuit Board (PCB) printing is a crucial step in the manufacturing process of electronic devices. It involves creating a pattern of conductive tracks, pads, and other features onto a substrate material, typically fiberglass or plastic. Proper PCB printing ensures that the electronic components are correctly […]

-

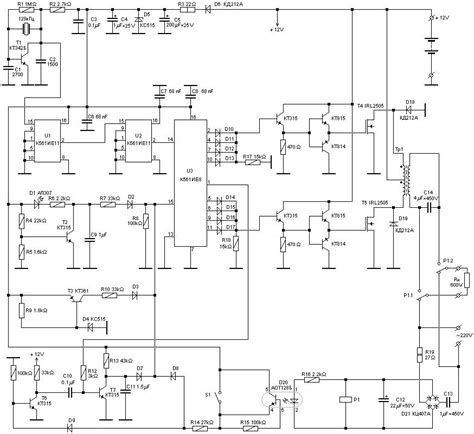

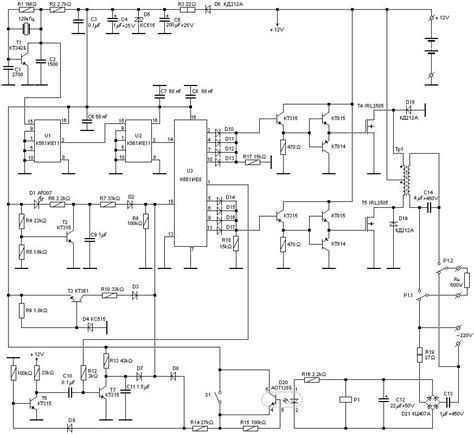

Read more: UPS Circuit – Easily Build Emergency Backup Battery Systems

Read more: UPS Circuit – Easily Build Emergency Backup Battery SystemsWhat is a UPS Circuit? A UPS circuit, or uninterruptible power supply circuit, is an electronic system that provides backup power to connected devices in the event of a power outage or fluctuation. It consists of a battery, charging circuit, inverter, and control circuitry. When the main power supply is […]

-

Read more: PCBA Services – How to Order Assembled Prototypes & Small Series.

Read more: PCBA Services – How to Order Assembled Prototypes & Small Series.Introduction to PCBA Services PCBA (Printed Circuit Board Assembly) services are essential for businesses and individuals who require high-quality, assembLED Circuit boards for their projects. Whether you need prototypes or small series production, PCBA services can help you bring your electronic designs to life. In this comprehensive article, we will […]

-

High Current PCB Design and Its Applications

Posted by

–

Read more: High Current PCB Design and Its Applications

Read more: High Current PCB Design and Its ApplicationsUnderstanding High Current in PCBs Before diving into the design aspects, it’s important to understand what constitutes “high current” in the context of PCBs. The definition of high current can vary depending on the specific application and the PCB’s size. However, as a general guideline, a PCB is considered to […]

-

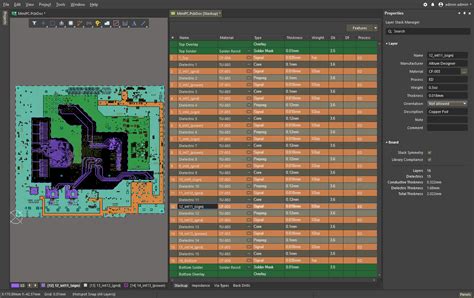

8 rules for designing PCB stack up

Posted by

–

Read more: 8 rules for designing PCB stack up

Read more: 8 rules for designing PCB stack upIntroduction to PCB Stack-Up Printed Circuit Board (PCB) stack-up refers to the arrangement of layers in a PCB design. It is a crucial aspect of PCB design that determines the electrical performance, signal integrity, and manufacturability of the board. A well-designed PCB stack-up ensures that the signals are transmitted efficiently […]

-

Read more: UPS Circuit: Everything You Need To Know and More

Read more: UPS Circuit: Everything You Need To Know and MoreWhat is a UPS Circuit? A UPS circuit is an electronic system that provides backup power to connected devices in case of a power failure or instability. It ensures that the connected load continues to receive power without any interruption, even if the main power source is lost. UPS circuits […]

-

Read more: Why are Motherboards Green: The Secret Behind PCB Colors

Read more: Why are Motherboards Green: The Secret Behind PCB ColorsIntroduction to Motherboards and PCB Colors Motherboards are the backbone of every computer system, connecting all the essential components and enabling them to communicate with each other. One of the most distinctive features of motherboards is their vibrant green color. Have you ever wondered why motherboards are predominantly green? In […]

-

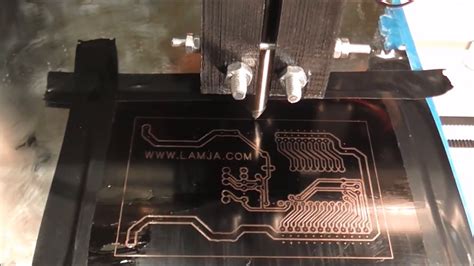

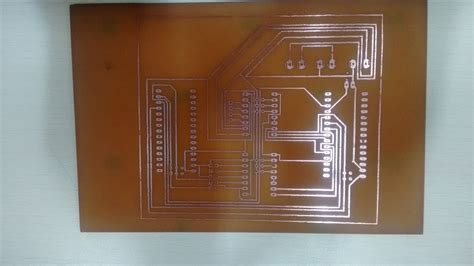

How To Make The Etching PCBs

Posted by

–

Read more: How To Make The Etching PCBs

Read more: How To Make The Etching PCBsWhat is PCB Etching? PCB etching is the process of creating custom printed circuit boards (PCBs) by selectively removing copper from a copper-clad board using a chemical etchant solution. This allows you to create the copper traces and pads that electrically connect components on the PCB. PCB etching is commonly […]