ALL ABOUT FLEX PCB

-

ATMega328P: A Detailed Explanation

Posted by

–

Read more: ATMega328P: A Detailed Explanation

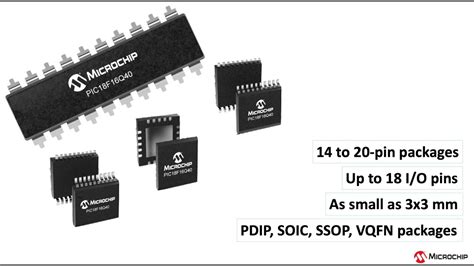

Read more: ATMega328P: A Detailed ExplanationMicrocontroller Overview The ATMega328P is a popular 8-bit microcontroller from Microchip’s AVR family. It is widely used in various applications, including Arduino boards, due to its versatility, low power consumption, and robust feature set. In this comprehensive article, we will dive deep into the ATMega328P, exploring its architecture, peripherals, and […]

-

Glx PCB Main-Using to Clean Your Pool

Posted by

–

Read more: Glx PCB Main-Using to Clean Your Pool

Read more: Glx PCB Main-Using to Clean Your PoolIntroduction to PCB Pool Cleaning Swimming pools are a great way to cool off during hot summer days, but they require regular maintenance to keep them clean and safe for use. One important aspect of pool maintenance is ensuring that the water is properly sanitized and free from harmful bacteria […]

-

Read more: Single Board Computer- How To Quickly Capture Our Social Market

Read more: Single Board Computer- How To Quickly Capture Our Social MarketIntroduction to Single Board Computers (SBCs) Single board computers (SBCs) are compact, self-contained computer systems built on a single circuit board. They include all the essential components of a functional computer such as a microprocessor, memory, input/output ports, and other features needed for a complete computing experience. SBCs are designed […]

-

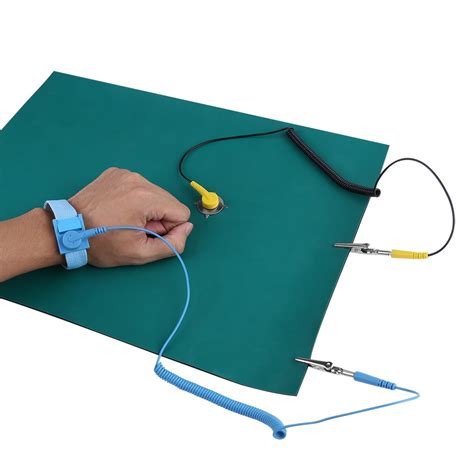

Read more: ESD Protection–How ESD Creates an Anti-Static Environment

Read more: ESD Protection–How ESD Creates an Anti-Static EnvironmentWhat is ESD? ESD is the sudden flow of electricity between two objects with different electrical potentials. It can occur when an electrically charged object, such as a person or a tool, comes into contact with an electrically sensitive object, such as an electronic component or device. ESD can generate […]

-

Read more: SMD Polarity Identification of LED, Capacitor, Diode, Inductor, IC

Read more: SMD Polarity Identification of LED, Capacitor, Diode, Inductor, ICTable of Contents Introduction to SMD Components SMD LED Polarity Identification SMD

-

Ultimate Guide to Printed Circuit Board Storage

Posted by

–

Read more: Ultimate Guide to Printed Circuit Board Storage

Read more: Ultimate Guide to Printed Circuit Board StorageFactors Affecting PCB Storage Several factors can impact the quality and longevity of stored PCBs. Understanding these factors is crucial in determining the best storage practices for your specific needs. Humidity Humidity is one of the most significant factors affecting PCB storage. Excessive moisture can lead to the growth of […]

-

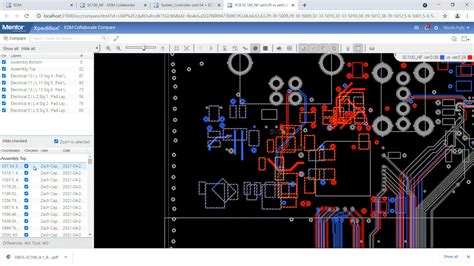

Optimum PCB Design Flow

Posted by

–

Read more: Optimum PCB Design Flow

Read more: Optimum PCB Design FlowIntroduction to PCB Design Flow Printed Circuit Board (PCB) design is a complex process that involves multiple steps and considerations. To ensure a successful PCB design, it is essential to follow an optimized design flow that encompasses all the necessary stages from concept to manufacturing. In this article, we will […]

-

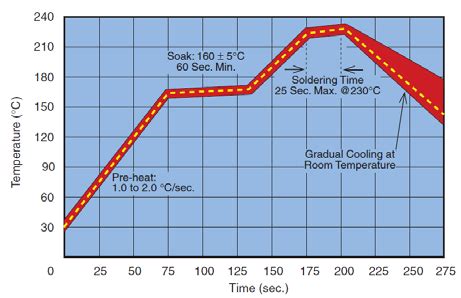

Read more: Solder profiles and oven parameters for the eC-reflow-mate

Read more: Solder profiles and oven parameters for the eC-reflow-mateIntroduction to Solder profiles Solder profiles are critical parameters that define the temperature curve followed during the reflow soldering process. Proper solder profiles ensure reliable solder joints, minimize thermal stress on components, and prevent defects such as bridging, tombstoning, and delamination. When using the eC-reflow-mate, understanding and optimizing solder profiles […]

-

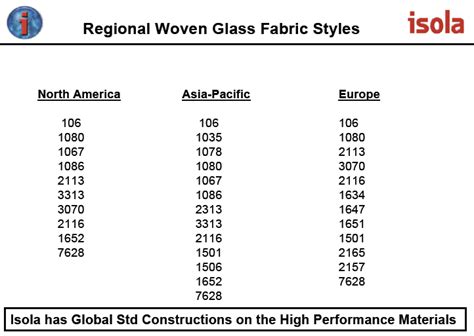

What is PCB Prepreg?

Posted by

–

Read more: What is PCB Prepreg?

Read more: What is PCB Prepreg?Composition of PCB Prepreg PCB Prepreg is composed of two main components: Reinforcement fabric Thermosetting resin Reinforcement Fabric The reinforcement fabric used in PCB Prepreg is most commonly glass fiber, although other materials such as aramid or carbon fiber can be used for specific applications. The fabric is woven into […]

-

All you need to know about PCB Gold Fingers

Posted by

–

Read more: All you need to know about PCB Gold Fingers

Read more: All you need to know about PCB Gold FingersWhat are PCB Gold Fingers? PCB gold fingers, also known as edge connector contacts or gold-plated contacts, are the gold-plated pads or traces located on the edge of a printed circuit board (PCB). These gold-plated contacts are designed to connect the PCB to another device or connector, enabling electrical signals […]