ALL ABOUT FLEX PCB

-

FR4 Quality – What to Expect

Posted by

–

Read more: FR4 Quality – What to Expect

Read more: FR4 Quality – What to ExpectWhat is FR4? FR4 is a composite material made from woven fiberglass cloth impregnated with an epoxy resin binder. The “FR” stands for “Flame Retardant,” indicating that the material has been treated to resist catching fire and spreading flames. The “4” in FR4 refers to the specific grade of the […]

-

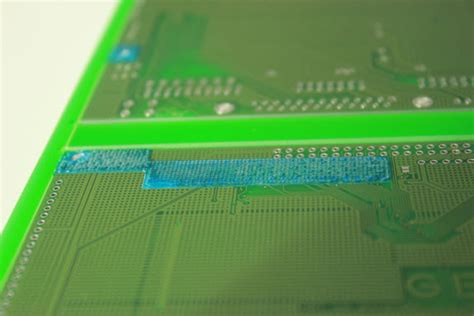

What is a Peelable Soldermask?

Posted by

–

Read more: What is a Peelable Soldermask?

Read more: What is a Peelable Soldermask?Introduction to Peelable Soldermask A peelable soldermask, also known as a temporary soldermask or removable soldermask, is a protective coating applied to printed circuit boards (PCBs) during the manufacturing process. This special type of soldermask is designed to be easily removed from specific areas of the PCB when needed, allowing […]

-

Read more: How does the parameter temperature correction work?

Read more: How does the parameter temperature correction work?What is temperature correction? Temperature correction is a method used to compensate for the influence of temperature variations on the measurement of a parameter. It involves adjusting the measured value of a parameter to account for the deviation caused by temperature changes. By applying temperature correction, the true value of […]

-

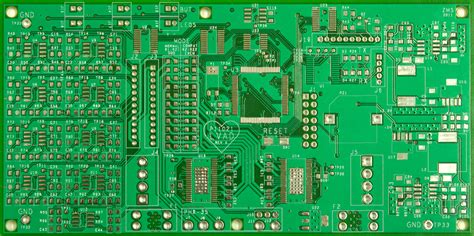

How to Upload PCB Data

Posted by

–

Read more: How to Upload PCB Data

Read more: How to Upload PCB DataIntroduction to PCB Data Upload Uploading PCB (printed circuit board) data is an essential step in the PCB design and manufacturing process. PCB data contains all the necessary information required to fabricate the physical circuit board, including the copper layers, drill holes, component footprints, and more. Properly preparing and uploading […]

-

Copper fills – mechanically speaking

Posted by

–

Read more: Copper fills – mechanically speaking

Read more: Copper fills – mechanically speakingIntroduction to Copper fills Copper fills, also known as copper vias or PTHs (plated through holes), are a crucial component in printed circuit boards (PCBs). They provide electrical connections between different layers of a multi-layer PCB, enabling the flow of signals and power throughout the board. From a mechanical perspective, […]

-

Review – Standard and Predefined Build-ups

Posted by

–

Read more: Review – Standard and Predefined Build-ups

Read more: Review – Standard and Predefined Build-upsWhat are Build-ups? Build-ups, in the context of construction and engineering, refer to the process of gradually increasing the complexity or size of a structure or system. This approach is commonly used in various fields, such as software development, manufacturing, and project management. The main purpose of build-ups is to […]

-

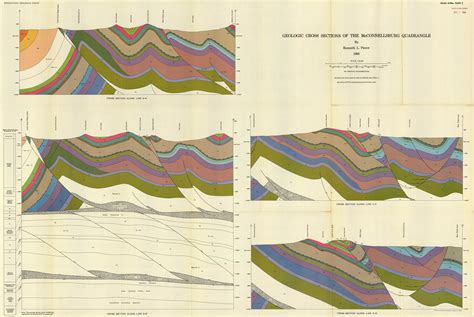

Cross Sections – What is their Purpose ?

Posted by

–

Read more: Cross Sections – What is their Purpose ?

Read more: Cross Sections – What is their Purpose ?What are Cross Sections? A cross section is a view of an object as if it had been sliced through to reveal its internal structure. Imagine cutting a loaf of bread in half and looking at the exposed surface – this is essentially a cross section. Cross sections can be […]

-

cEDM – Electronics Design & Manufacturing

Posted by

–

Read more: cEDM – Electronics Design & Manufacturing

Read more: cEDM – Electronics Design & ManufacturingIntroduction to cEDM cEDM, or Collaborative Electronic Design and Manufacturing, is a groundbreaking approach that combines the power of collaborative design with the efficiency of modern manufacturing techniques. This innovative methodology is transforming the way electronics are designed and produced, enabling companies to bring their products to market faster, more […]

-

ENEPIG vs ENIG: Which Surface Finish is Better?

Posted by

–

Read more: ENEPIG vs ENIG: Which Surface Finish is Better?

Read more: ENEPIG vs ENIG: Which Surface Finish is Better?What is ENEPIG? ENEPIG is a surface finish that consists of three layers: electroless nickel, electroless palladium, and immersion gold. The process involves depositing a layer of electroless nickel onto the copper pads of the PCB, followed by a thin layer of electroless palladium, and finally, a layer of immersion […]

-

Guide to Lead Free Soldering and Reflow Profile

Posted by

–

Read more: Guide to Lead Free Soldering and Reflow Profile

Read more: Guide to Lead Free Soldering and Reflow ProfileUnderstanding Lead Free Soldering Lead-free soldering is the process of joining two or more metal surfaces using a lead-free solder alloy. The most common lead-free solder alloys are tin-silver-copper (SAC) alloys, with the most popular being SAC305 (96.5% tin, 3% silver, and 0.5% copper). Advantages of Lead Free Soldering Environmentally […]